Cleaning equipment and method for high-strength cutting blades

A technology for cutting blades and cleaning equipment, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as affecting cleaning effects, cleaning omissions, and adhered oil stains, so as to improve cleaning effects , Improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

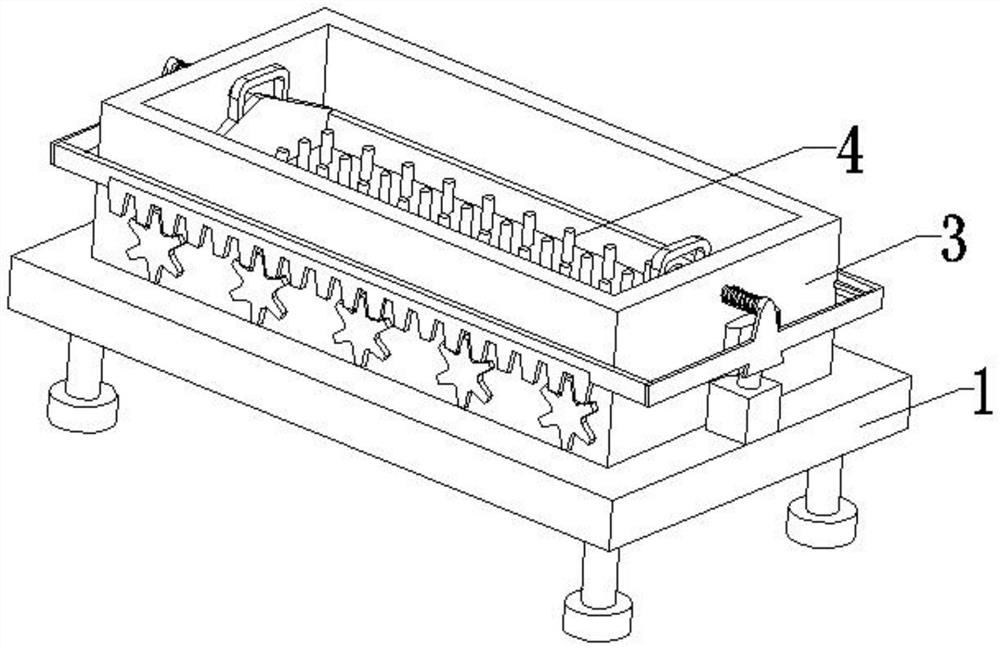

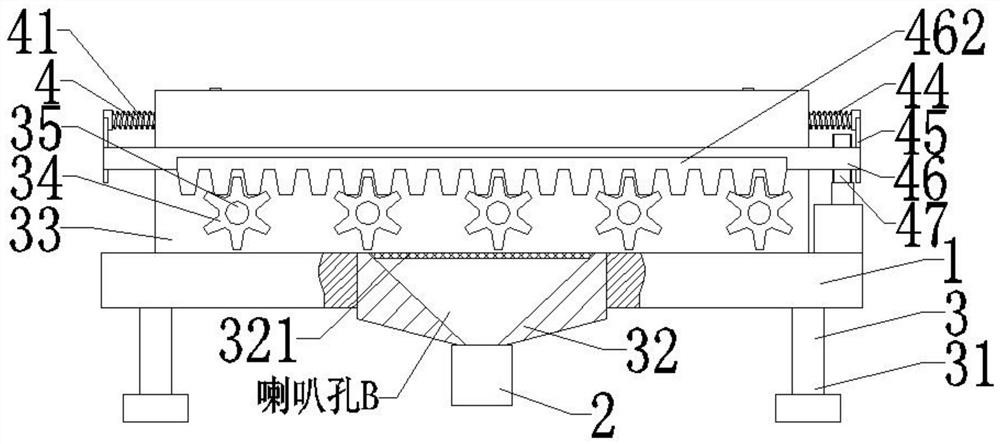

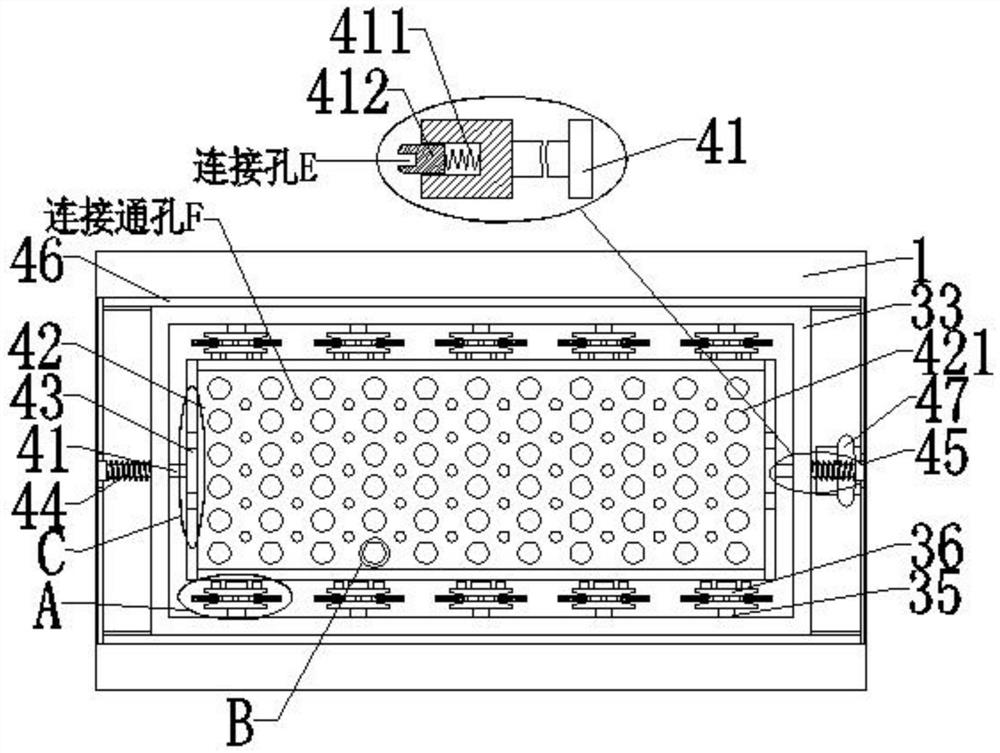

[0031] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 7 , the present invention will be further elaborated.

[0032] A cleaning device for a high-strength cutting blade, comprising a mounting substrate 1, an ultrasonic transmitter 2, a cleaning assembly 3 and a material setting assembly 4, an ultrasonic transmitter 2 is fixedly mounted on the lower end surface of the mounting substrate 1, and an ultrasonic transmitter 2 is fixedly mounted on the mounting substrate 1. The cleaning component 3, the cleaning component 3 is installed with a material holding component 4 by means of sliding connection, wherein:

[0033]The cleaning assembly 3 includes a support rod 31, a diffusion block 32, a cleaning box 33, a rotating toothed plate 34, a rotating column 35 and a stirring block 36. The support rod 31 is fixedly installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com