Unequal-diameter three-roller grinding machine

A technology of three-roll grinding machine and equal diameter, which is applied in the field of grinding machines, can solve the problems of material temperature rise, inappropriateness, and complex structure, and achieve the effects of increasing grinding shear force, improving grinding effect, and reducing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

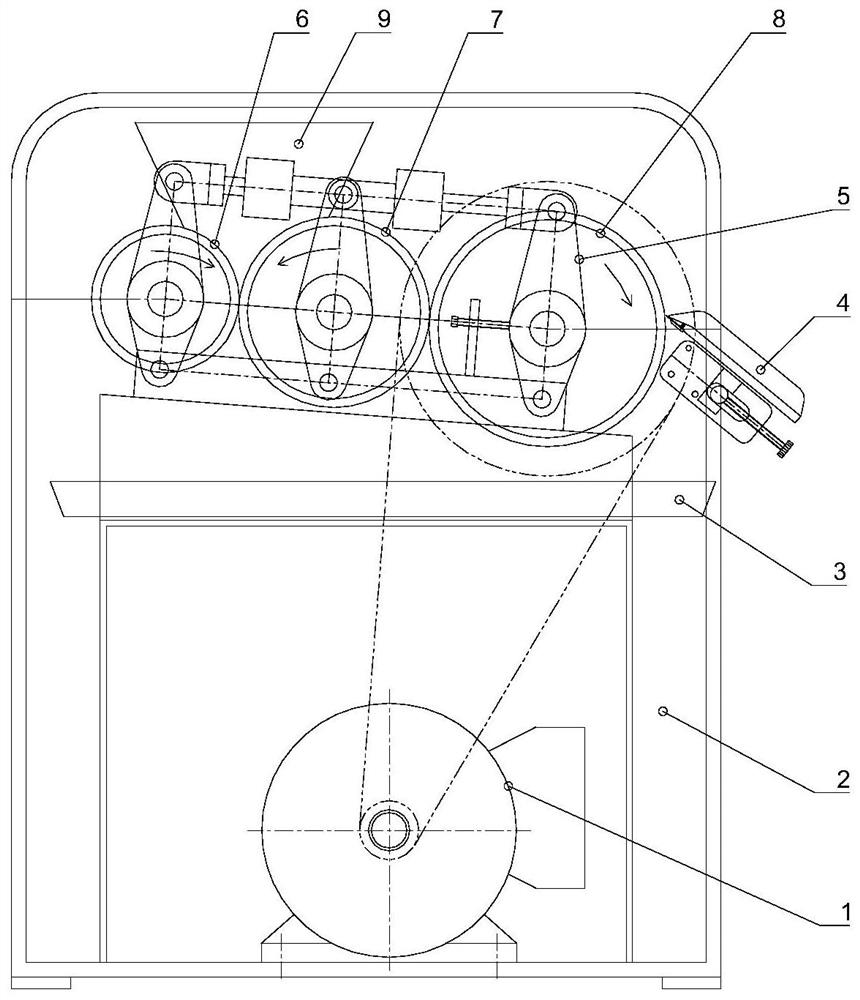

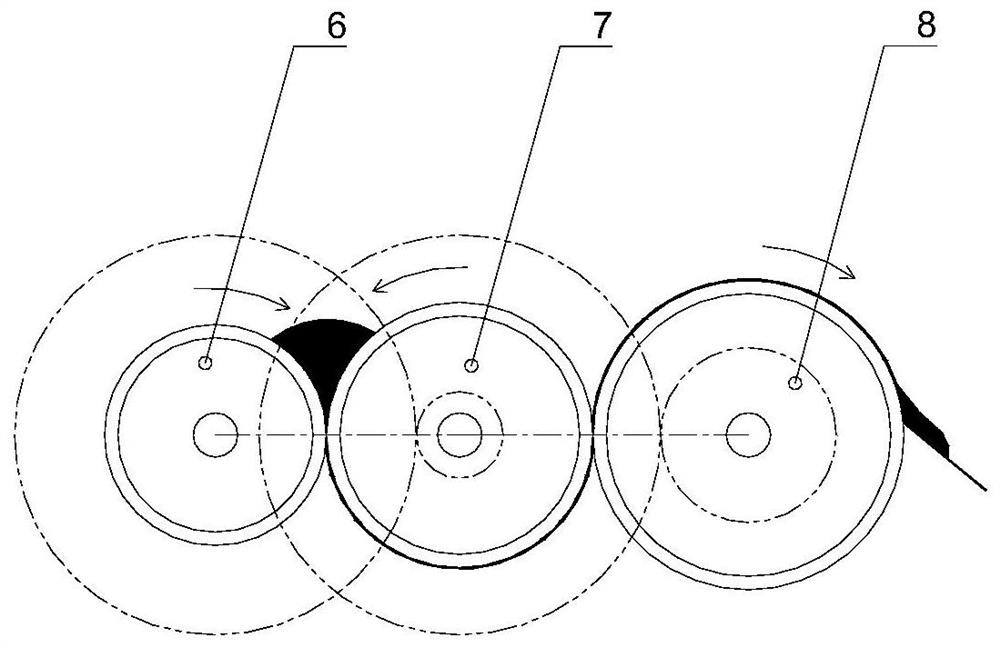

[0036] figure 2 and 3Shown is the overall structure diagram and operation diagram of the three rollers of the unequal diameter three-roll mill arranged in a straight line. The unequal-diameter three-roll mill includes a frame 2, an inlet roller 6, an intermediate roller 7, an outlet roller 8 and a prime mover 1, and the inlet roller 6, the intermediate roller 7, and the outlet roller 8 pass through the bearing mounting seat 5 in turn. Installed on the frame 2, one side of the discharge roller 8 is provided with a discharge roller 8 scraper 4, the blade of the discharge roller scraper 4 can be adjusted to press the discharge roller 8; the feed roller 6, the middle roller 7, the discharge roller The diameter of 8 increases step by step; the axis connection line between the feed roller 6 and the intermediate roller 7 and the axis connection line between the intermediate roller 7 and the discharge roller 8 are arranged in a straight line; the feed roller 6 , Intermediate roll 7...

Embodiment 2

[0039] Figure 4 Shown is a schematic diagram of the overall structure in which the three rollers of the unequal diameter three-roll mill are arranged in a non-line shape; Figure 5 Shown is a schematic diagram of an arrangement of three rollers. The difference from Embodiment 1 is that the axis connecting line between the feeding roller 6 and the intermediate roller 7 and the axis connecting line between the intermediate roller 7 and the discharging roller 8 are not arranged in a straight line. The unequal-diameter three-roll mill can use prime mover 1 to provide power for the feed roller 6, intermediate roller 7, and discharge roller 8, and the feed roller 6 and intermediate roller 7 are connected by gears with different transmission ratios. The intermediate roller 7 and the discharge roller 8 are connected by gears with different transmission ratios, see Figure 5 , by setting gears with different gear ratios, the linear velocity of the relative movement of the rollers is...

Embodiment 3

[0041] The unequal-diameter three-roll mill of this embodiment is more suitable for grinding materials that are more sensitive to temperature increase (such as ink and paint materials). see Figure 6 , the unequal-diameter three-roller grinder includes frame 2, feeding roller 6, intermediate roller 7, discharging roller 8 and prime mover 1, feeding roller 6, intermediate roller 7 and discharging roller 8 pass through bearing mount 5 Installed on the frame 2 in turn, one side of the discharge roller 8 is provided with a discharge roller scraper 4, the blade of the discharge roller scraper 4 can be adjusted to press the discharge roller 8; the feed roller 6, the intermediate roller 7, the discharge roller The diameters of 8 are not completely the same or completely different; the axis connecting line between the feeding roller 6 and the intermediate roller 7 and the axis connecting line between the intermediate roller 7 and the discharging roller 8 are arranged in a V shape; Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com