Clean non-pressure-storage fire extinguisher

A fire extinguisher and clean technology, applied in the field of clean non-pressure storage fire extinguishers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

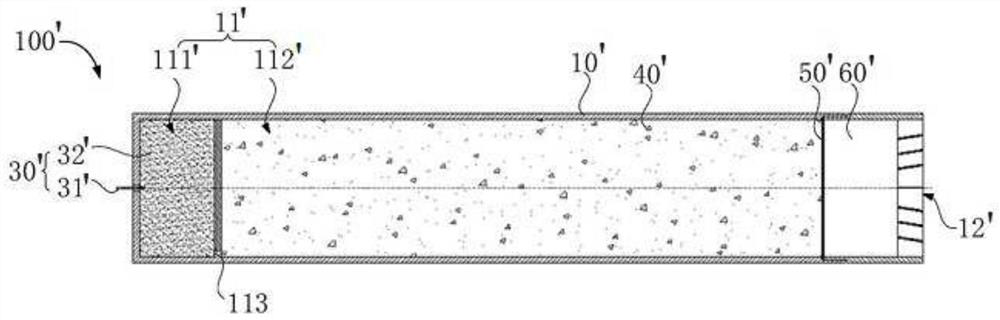

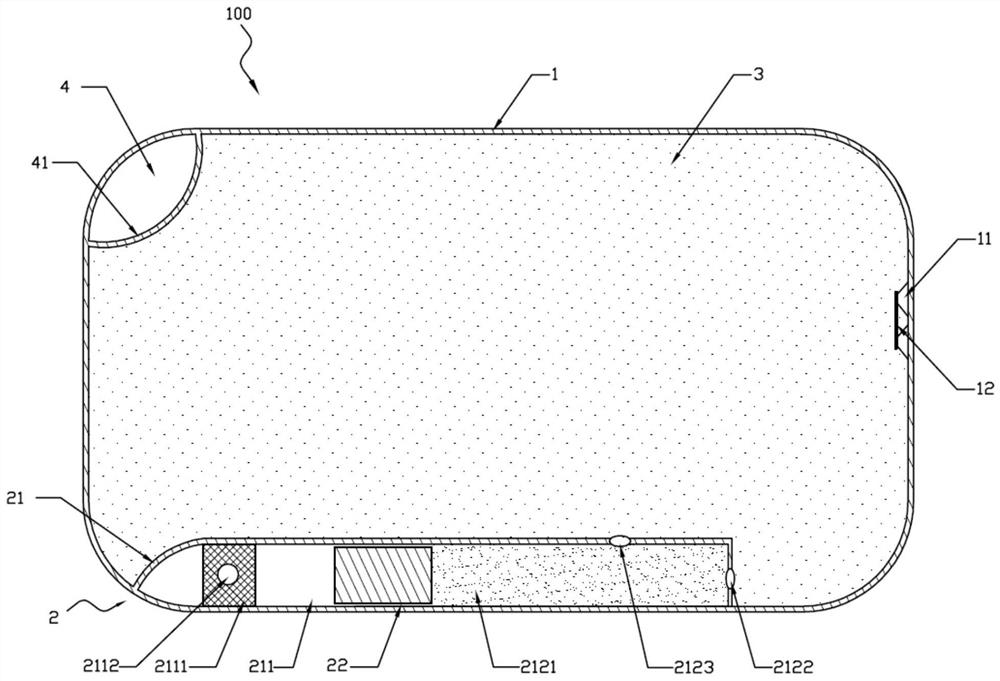

[0029] Such as figure 2 As shown, this embodiment provides a clean non-pressure storage fire extinguisher 100, which mainly includes a fire extinguishing agent storage tank 1 and an eruption power device 2, wherein the fire extinguishing agent storage tank 1 is filled with a liquid or gaseous fire extinguishing agent 3. The fire extinguishing agent 3 of the embodiment is preferably fluid perfluorohexanone.

[0030] The side wall of the fire extinguishing agent storage tank 1 is provided with at least one spout 11, and the spout 11 is closed by a first safety diaphragm 12, so that the perfluorohexanone fire extinguishing agent 3 is stored in a closed environment, which is suitable for long-term storage. The first safety diaphragm 12 is in the shape of a film and will rupture when reaching a critical pressure value. Based on this, the present embodiment uses the eruption power device 2 to provide pressurization, so that the air pressure in the fire extinguishing agent storage ...

Embodiment 2

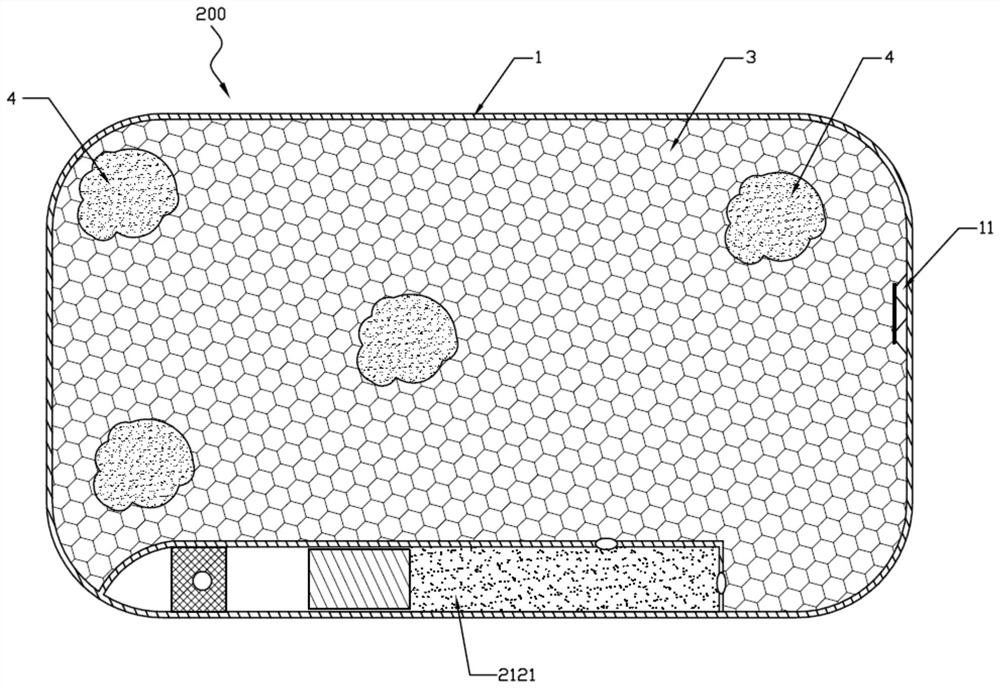

[0042] refer to image 3 As shown, this embodiment provides another clean non-pressure storage fire extinguisher 200. The structure of the clean non-pressure storage fire extinguisher 200 is basically the same as that of the fire extinguishing device shown in Embodiment 1. The main difference is that the embodiment The fire extinguishing agent in one is fluid perfluorohexanone, and the fire extinguishing agent 3 of this embodiment is several perfluorohexanone capsules packaged into small particles, and these perfluorohexanone capsules are squeezed by high temperature and high pressure gas After that, it can also be sprayed out through the nozzle 11 to implement fire extinguishing.

[0043] Another difference is that since the fire extinguishing agent storage tank 1 is filled with full perfluorohexanone capsules, and there are gaps between the perfluorohexanone capsules, the pre-stored resistance in the pressure chamber 212 as the pressurization power The combustible substance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com