Pattern making method of female casual jacket

A jacket and women's technology, applied in the field of clothing, can solve the problems of inaccurate shoulder slanting angle, affecting the appearance of the image, and slanting threads appearing in the seam of the jacket.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

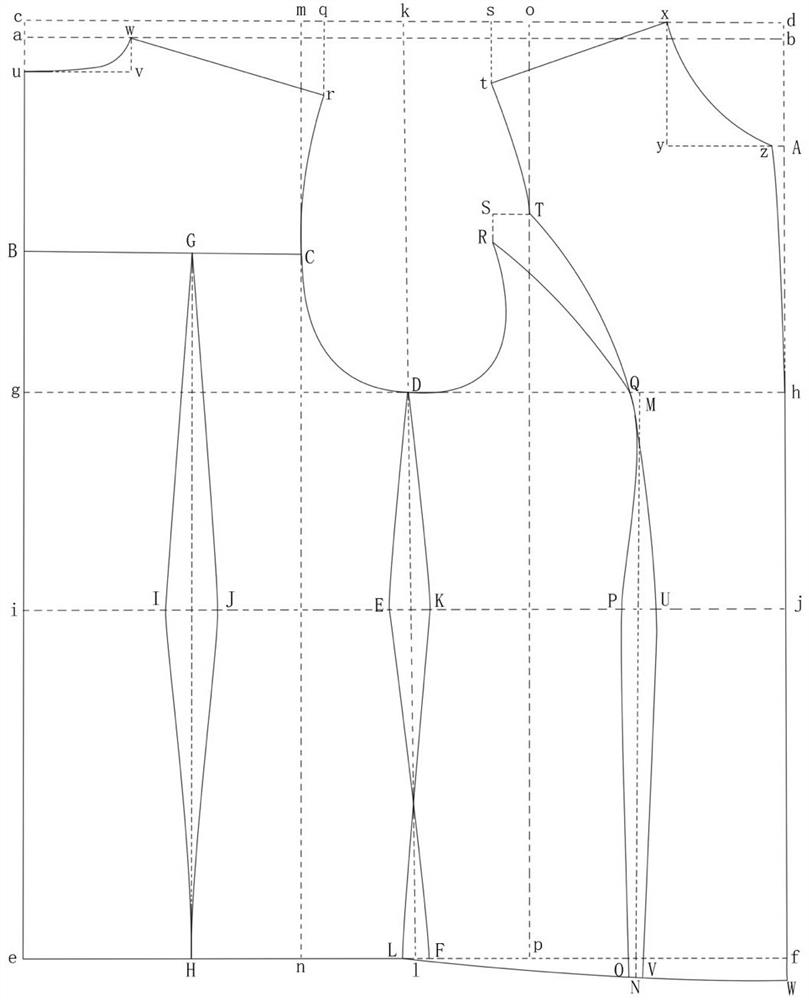

[0047] as attached figure 1 Shown, the plate-making method of women's casual jacket of the present invention, described women's casual jacket comprises two back garment parts of same structure and the same front garment part of structure respectively sewn on the outside of two rear clothes parts, so The back garment piece includes a back yoke and a rear lower panel sewed with the bottom edge of the back yoke, and the front garment piece includes a front side piece and a front knife back piece sewed with the side edge of the front side piece; The following steps are used to make a plate for the lower film, the front side film and the front knife back film:

[0048] Step 1. Make auxiliary lines;

[0049] (1) Make a rectangle cefd, and the line ef is the auxiliary line for the length of the back body;

[0050] (2) Draw parallel lines ab, gh and ij of line cd from top to bottom in the rectangle cefd; lines ab, gh and ij intersect line ce at points a, g and i respectively, lines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com