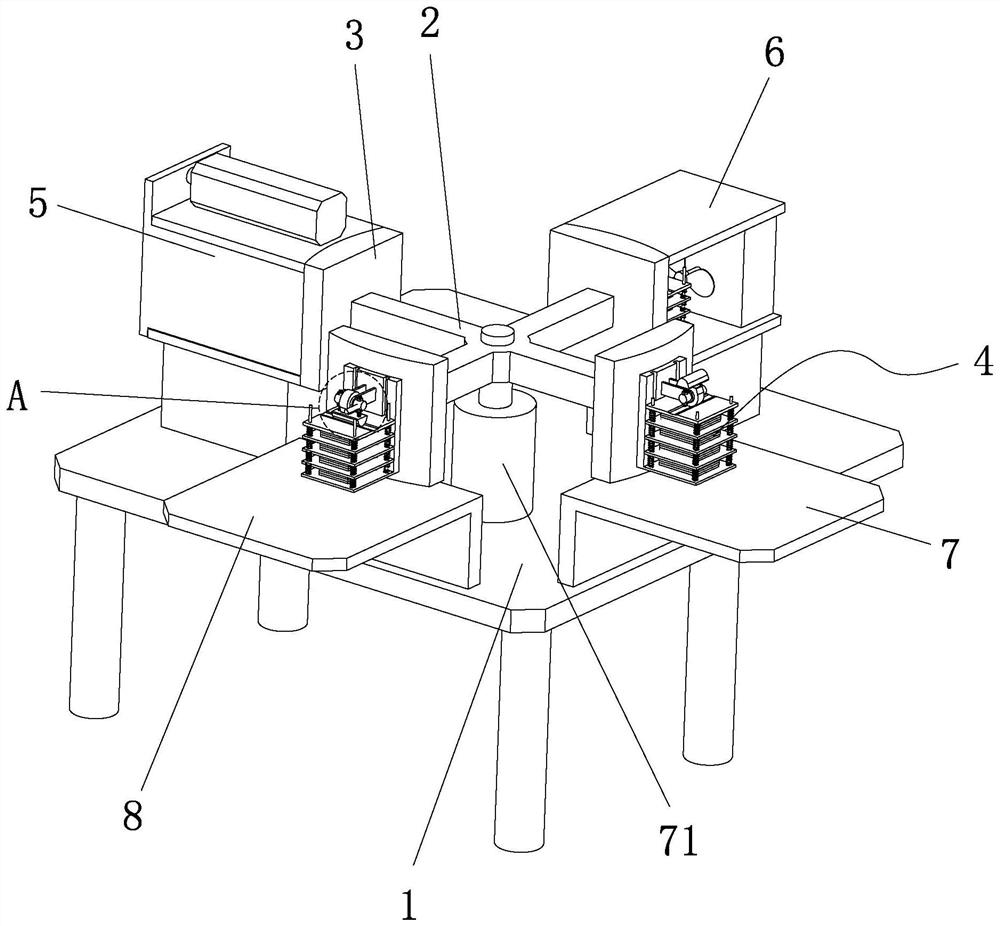

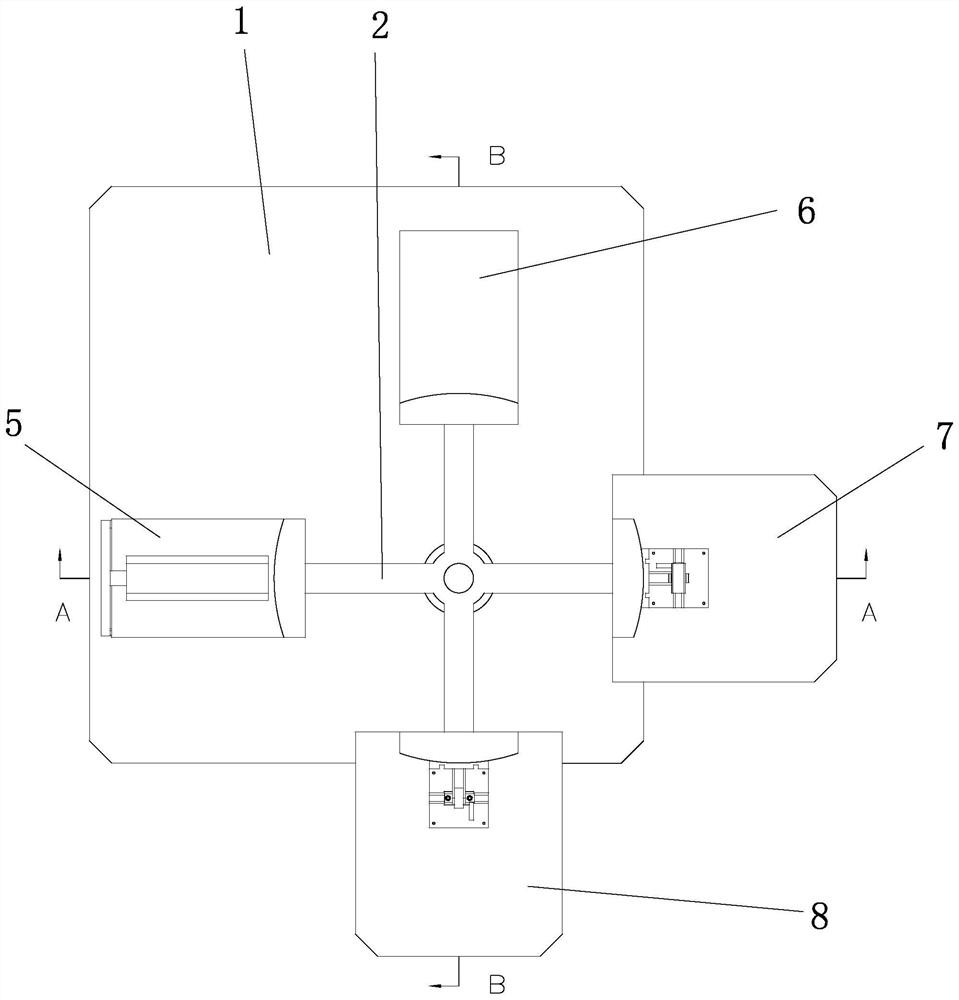

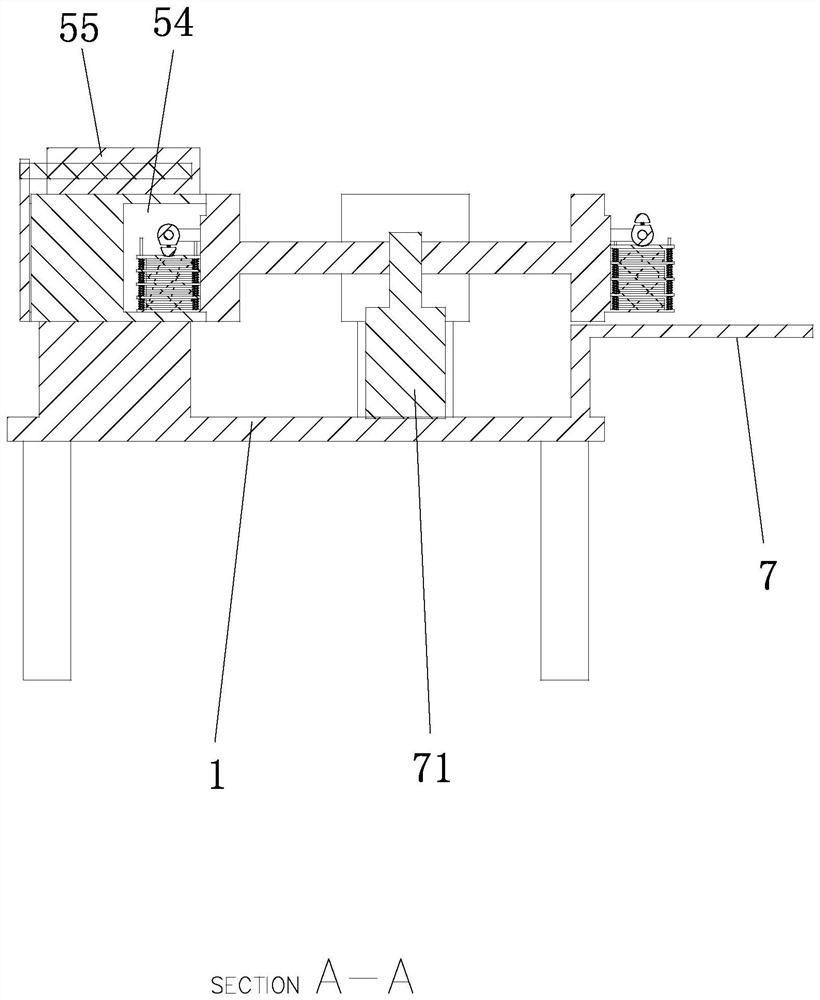

PCB correction equipment and correction method thereof

A PCB board and equipment technology, applied in the field of PCB board correction equipment, can solve problems such as secondary deformation, PCB board deformation, PCB board production process complexity, etc., to reduce processing time, high production efficiency, and realize semi-automatic production processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following detailed description provides various embodiments or examples for implementing the invention. Of course, these are merely embodiments or examples and are not intended to be limiting. In addition, repeated reference numerals, such as repeated numbers and / or letters, may be used in different embodiments. These repetitions are for the purpose of simply and clearly describing the present invention, and do not represent any specific relationship between the different embodiments and / or structures discussed.

[0029] In addition, terms related to space may be used, such as "below", "underside", "inside out", "above", "upper side" and similar terms, these relative words To facilitate describing the relationship between one element or feature and another element or feature in the drawings, these spatial relative terms include different orientations of the device in use or operation, as well as the orientation depicted in the drawings. The device may be turned to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com