Method for testing residual stress of steel thin welding plate with narrow welding seam characteristic

A technology of residual stress and weld characteristics, which is applied in the field of residual stress testing of thin steel welded plates, can solve the problems of inability to measure the direction of residual stress, the inability to achieve accurate positioning and measurement of residual stress in narrow welds, and the difficulty of accurate measurement, achieving an improvement The effect of production process and welding process efficiency and quality stability, fast and accurate detection, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

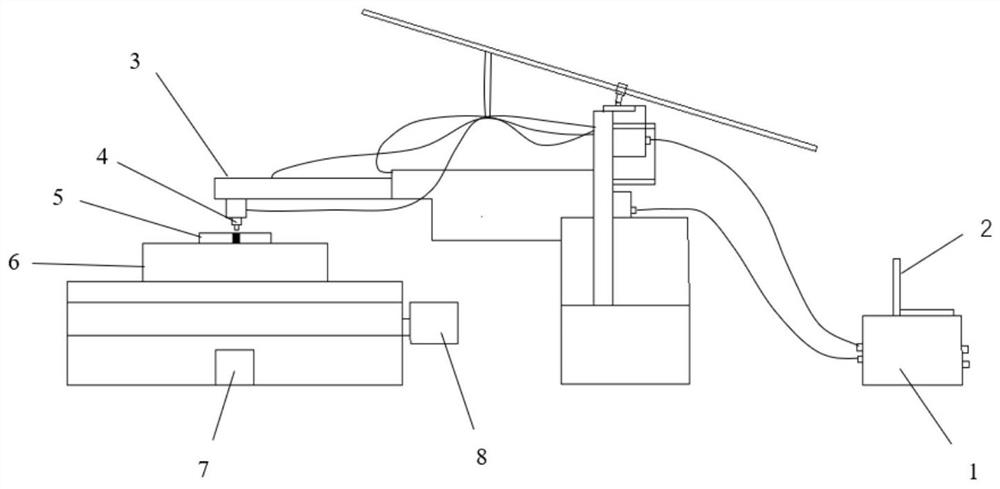

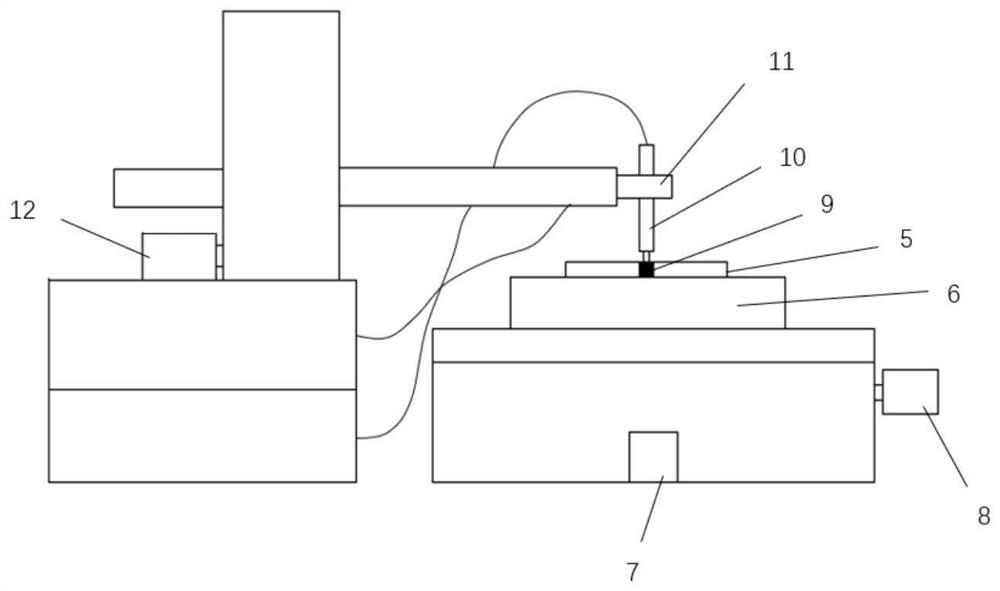

[0024] In order to make the purpose, technical scheme and advantages of the present invention clearer, the accompanying drawings will be used below to detect the residual stress of thin steel welded plates for cruise ships with narrow weld characteristics and the residual stress of the narrow weld surface to the depth of 1mm. The embodiment describes in detail the details of the technical solution of the present invention.

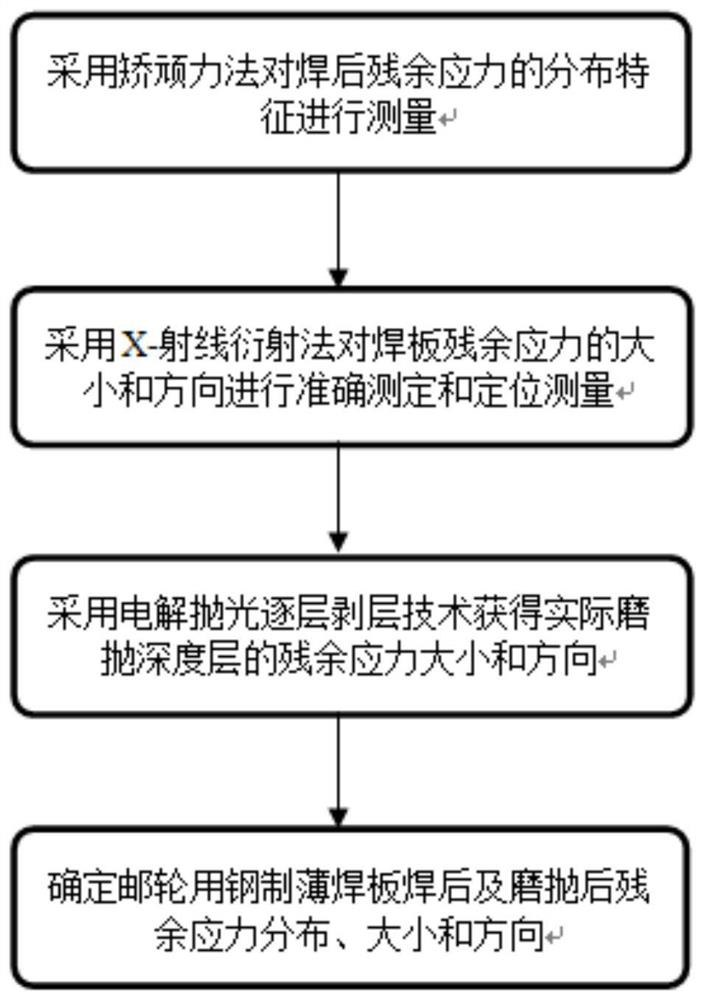

[0025] Such as figure 1 As shown, a method for testing the residual stress of thin steel welded plates with narrow weld features includes the following steps:

[0026] The first step is to use the coercive force method to measure the distribution characteristics of the residual stress of the steel thin welded plate for cruise ships after welding.

[0027] The principle of the coercive force method is to use the magnetic method to measure the residual stress of the material. Under the action of the working load, the ferromagnetic workpiece in the geomagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com