One-time detonation method for large-section tunnel

A detonation method and large-section technology, which are used in tunnels, blasting, earth-moving drilling, etc., can solve the problem of large throwing range of flying stones, and achieve the effects of reducing the concentration of charges, reducing blasting vibration, and reducing vibration peaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for primary detonation of large-section tunnels, which is suitable for drilling and blasting excavation construction of large-section tunnels in mines, especially under the condition of using an integrated drilling, loading, and transporting tunneling machine. The steps include:

[0042] S1. Divide the excavation section into upper and lower steps, and the upper step is arranged ahead of the lower step; the distance between the upper step and the lower step is greater than the length of the excavation cycle.

[0043] S2. Peripheral holes are arranged along the excavation contour of the upper step, and explosives are installed in the peripheral holes.

[0044] S3. Arrange a plurality of hole vertical lines evenly along the vertical direction on the upper step, and arrange a plurality of hole horizontal lines parallel to the tunnel floor on the upper step to determine the base point of the hole; the intersection point between the hole vertical line and the hole fl...

Embodiment 2

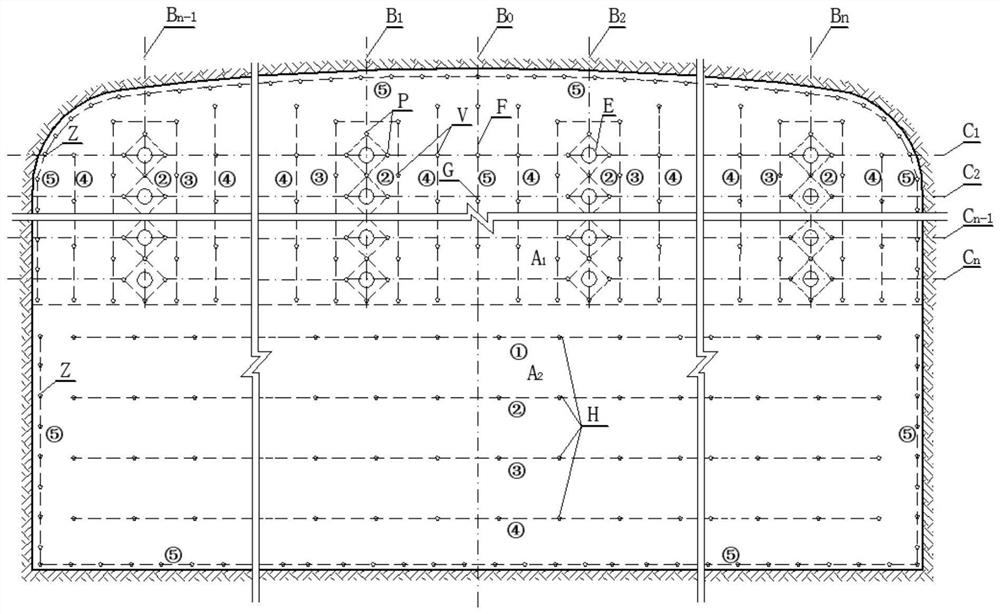

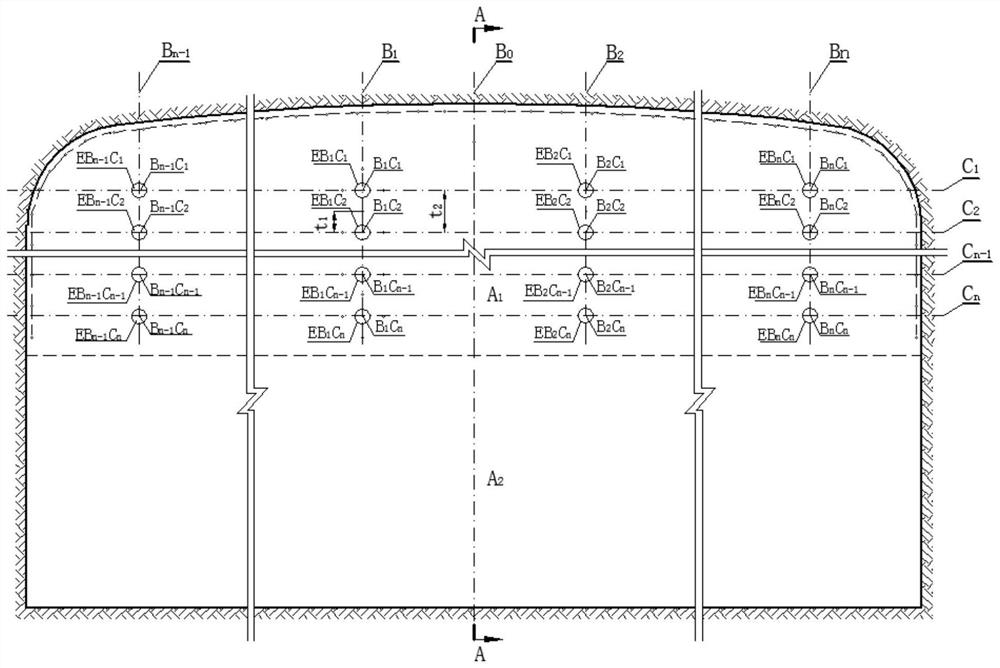

[0056] combine Figure 1 to Figure 3 A method for one-time detonation of a large-section tunnel is described in detail, and the steps may specifically include:

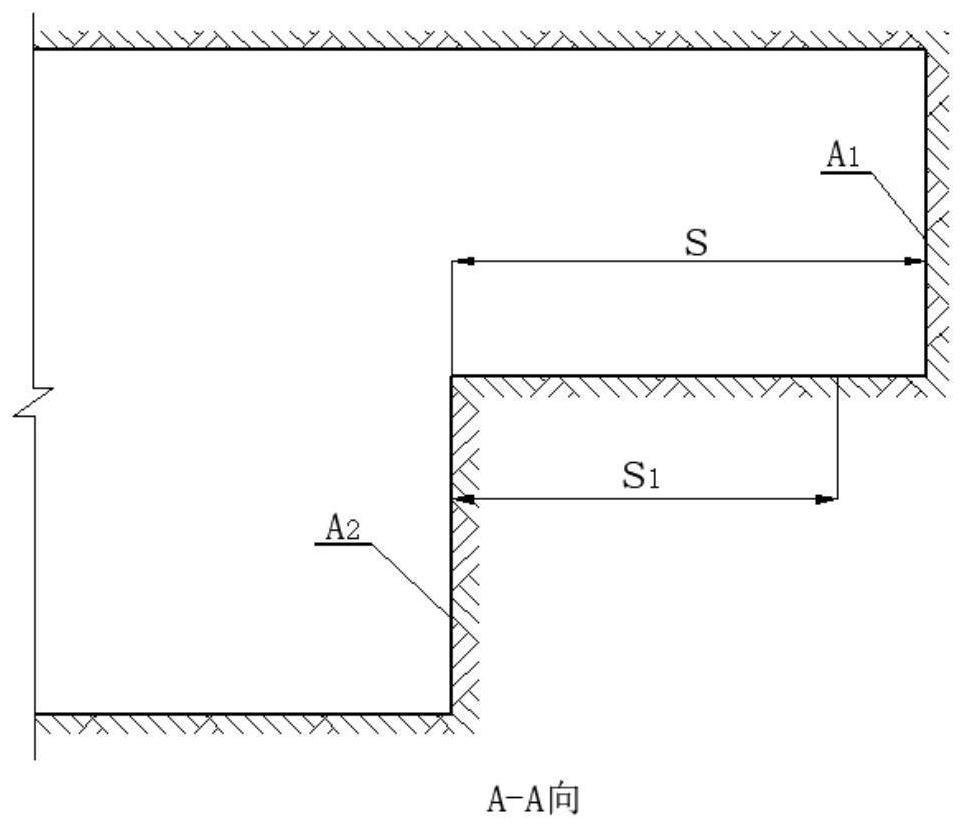

[0057] S1. Divide the excavation section A into upper steps A 1 and down step A 2 Two steps, go up to step A 1 A step ahead 2 A certain distance s, the length of s is greater than the length s of a tunneling cycle 1 ;

[0058] S2. Go up the steps A 1 and down step A 2 The excavation contour line arranges the peripheral hole Z.

[0059] S3. Go up the steps A 2 Perpendicular line B 0 On both sides of , symmetrically arrange i parallel to the vertical line B 0 Hole Perpendicular B 1 , B 2 , B 3 ,...,B i , i≥2,; on the upper step A 2 The horizontal line C of the hole is arranged parallel to the tunnel floor 1 、C 2 、C 3 ,...,C j , j≥1; hole flat line C j and perpendicular line B 0 The intersection point is hole base point B 0 C j , hole perpendicular B 1 , B 2 , B 3 ,...,B i with hole level C 1 ...

Embodiment 3

[0069] Taking the track lane at the west wing of a certain mine as an example, a method of primary detonation for a large-section tunnel is described in detail.

[0070] Such as Figure 4 As shown, the roadway is a straight wall semi-circular arch section, the excavation width is 5.90m, the excavation height is 5.45m, the wall height is 2.50m, and the excavation section area is 28.4m 2 . The diameter of the empty hole E used in the example is 113mm, and the diameter of the expanded hole P is 42mm. Using the large-section tunnel primary detonation method of the present invention in roadway excavation, the specific construction steps include:

[0071] Step 1: Divide the excavation section A into upper steps A 1 and down step A 2 Two sections, the height of the upper step is 2.90m. Design cycle length of excavation h=2.50m, upper step A 1 A step ahead 2 Distance s=4.00m.

[0072] Step 2: Go up Step A 1 The surrounding holes Z are arranged on the excavation contour line, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com