Ultra-large deepwater step type open caisson and soil taking strategy and construction method thereof

A construction method and step-type technology, applied in caisson, infrastructure engineering, construction and other directions, can solve the problems of increasing the scouring effect of water flow on the pier foundation, increasing the cost of building bridge materials, increasing the weight of the caisson, etc. Operational efficiency, overall weight reduction, effect of reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

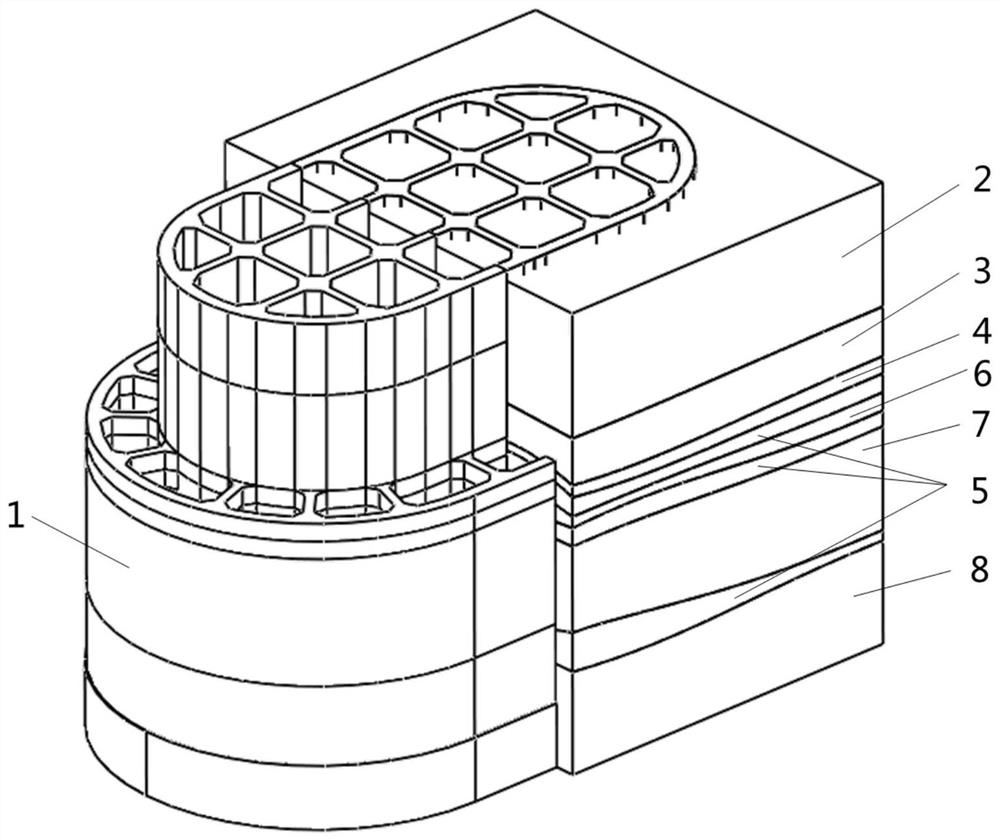

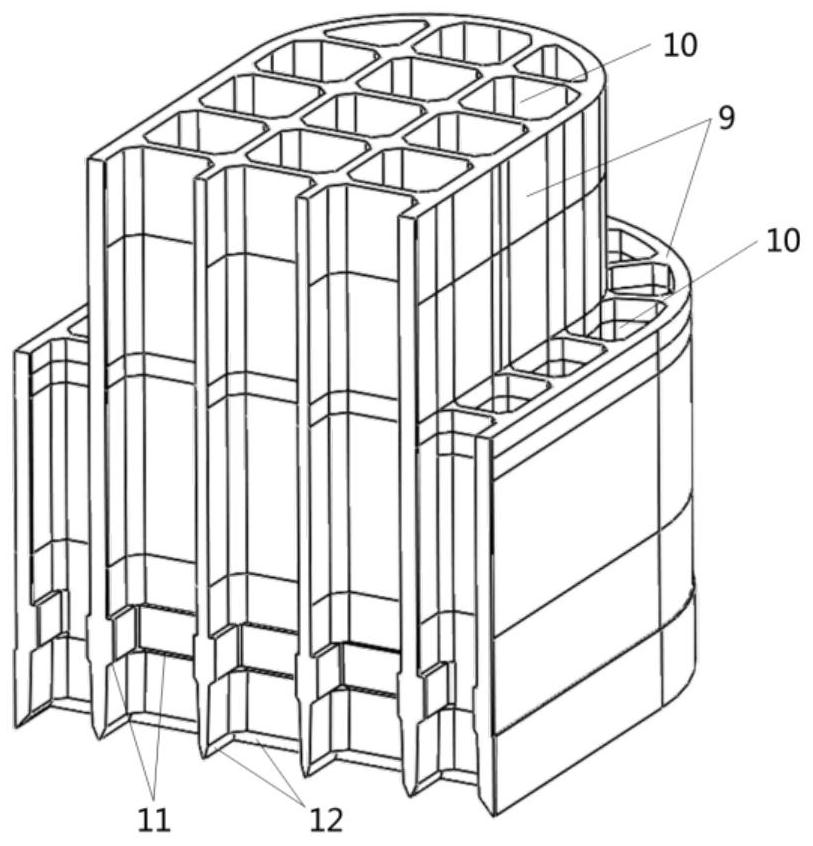

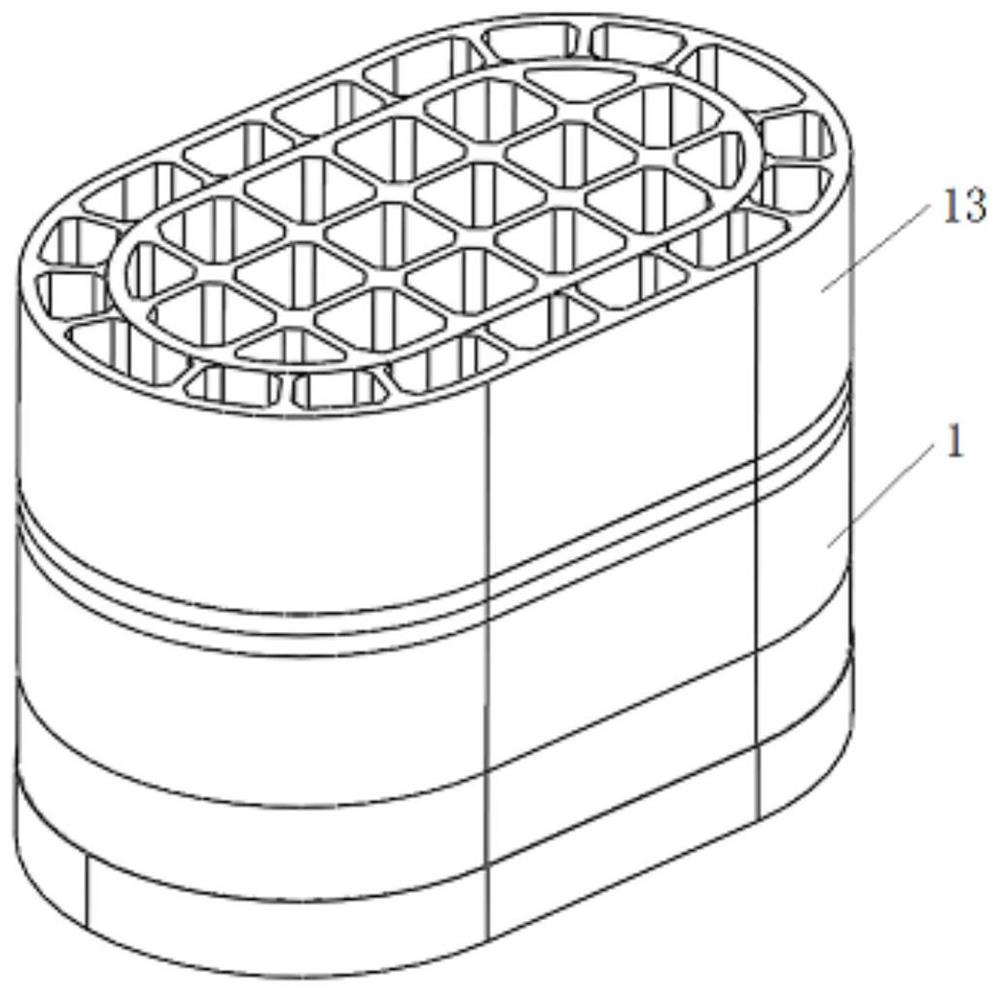

[0053] like Figures 1 to 7 As shown, in the embodiment given in this application, the overall plane size of the stepped caisson 1 is about 95m×58m, and the height is about 64m, and the height of the large caisson below the step is about 43m; The bottom elevation is about -65m. The stepped caisson 1 is a steel shell structure as a whole, the lower part is a large caisson and the upper part is a stepped structure with a small caisson. Both ends of the stepped caisson 1 are round-end structures. The top surface of the well is located under the mud surface, and the top surface of the upper small caisson is near the water surface; the stepped caisson 1 is composed of a well wall 9 and a wellbore 10 that penetrates up and down, and the middle of the well wall 9 is filled with concrete during the sinking process of the caisson; The lowermost end of the caisson 1 is a blade foot 11 structure, and about 9-15m above the blade foot 11 is a shear key 12 structure.

[0054] During the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com