Double-gas automatic adjustable atomizing nozzle

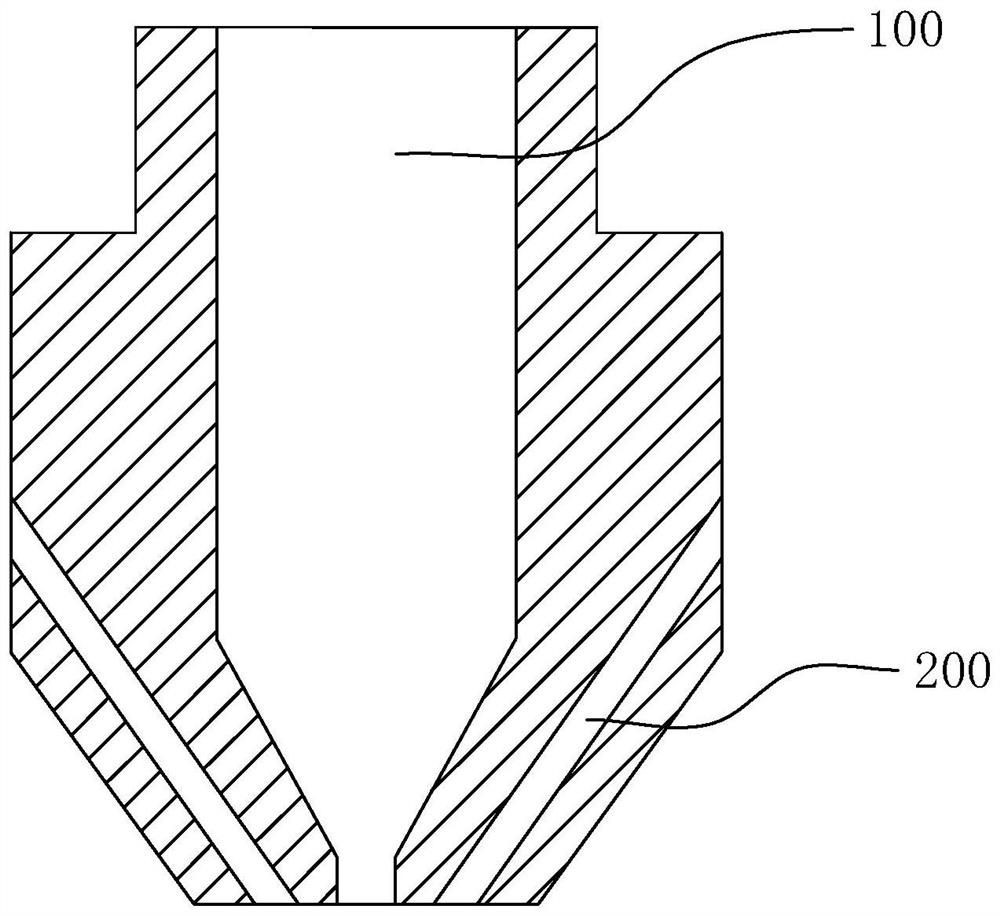

An atomizing nozzle, adjustable technology, applied in the direction of liquid spraying device, spraying device, etc., can solve the problems such as difficulty in forming spray in the spray center, small change range, general applicability, etc., to achieve convenient replacement and maintenance, and increase angle adjustment Gas volume, effect of improving spray uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

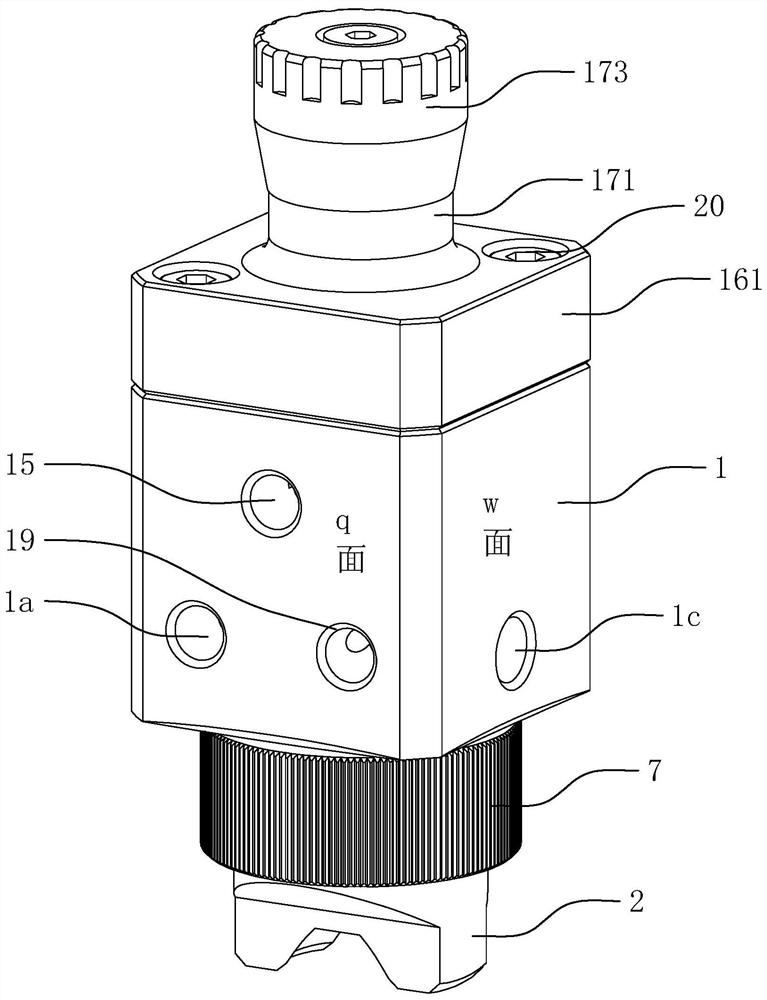

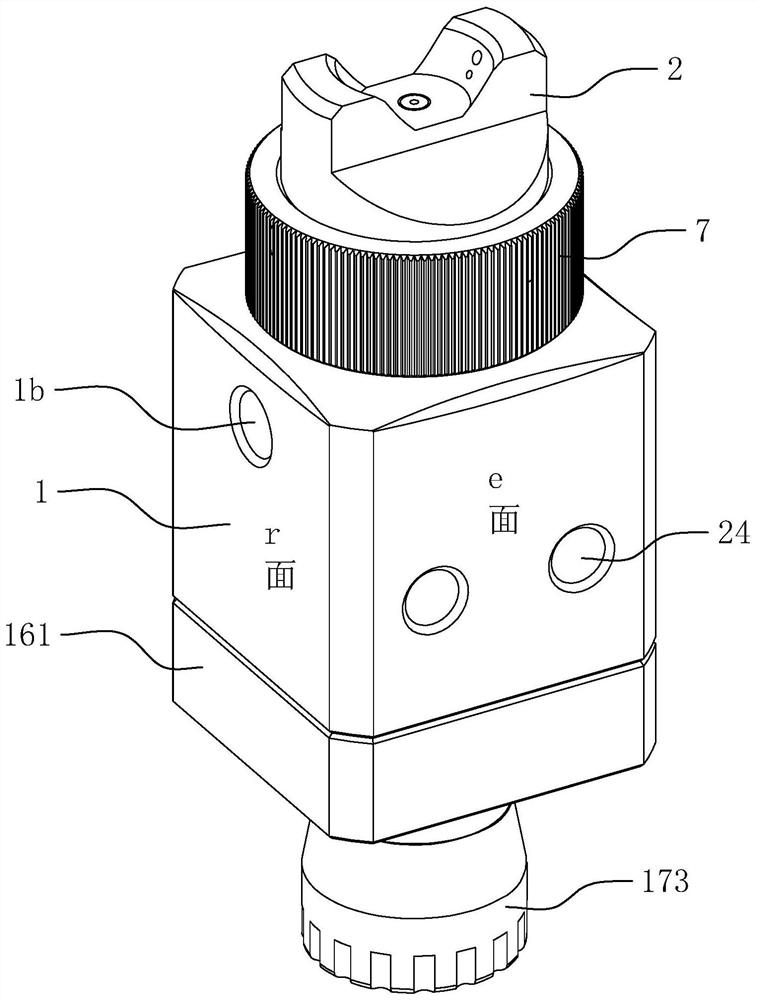

[0047] The following is attached Figure 2-7 The application is described in further detail.

[0048] refer to figure 2 , is a dual-gas automatic adjustable atomizing nozzle disclosed in the embodiment of this application. This dual-gas automatic adjustable atomizing nozzle includes a vertically arranged cuboid main body block 1, the main body block 1 is mainly used for gas and liquid, and a plurality of passages for gas or liquid are opened inside; The top of the main body block 1 is connected with an auxiliary body block 161 by countersunk head bolts 20, that is, the auxiliary body block 161 and the main body block 1 form a detachable connection; the upper surface of the auxiliary body block 161 is vertically and coaxially provided with a sleeve 171, a knob 173 is sheathed on the outer side wall of the sleeve 171, and the knob 173 can move vertically along the outer side wall of the sleeve 171 while rotating; a spraying part is detachably connected under the main body blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com