A kind of highly dispersed cobalt-iron bimetallic catalyst and its preparation method and application

A bimetallic catalyst and high-dispersion cobalt technology, applied in catalyst activation/preparation, molecular sieve catalysts, separation methods, etc., can solve the problems of low catalytic activity and limitation of catalyst dispersion degree, and achieve high catalytic activity and active site distribution Uniform, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

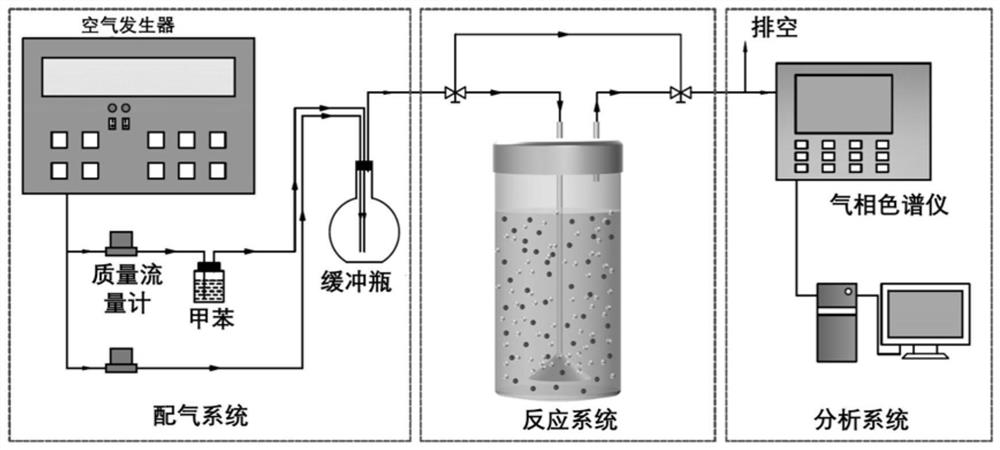

[0051] A preparation method of a highly dispersed cobalt-iron bimetallic catalyst, comprising the following steps:

[0052] S1. Weigh 1g of the prepared SBA-15 carrier in an agate mortar, add a precursor salt and grind for 30min, the precursor salt is 0.3152g Co(NO 3 ) 2 ·6H 2 O and 0.4618g Fe(NO 3 ) 3 ·9H 2 A mixture of O, the mass ratio of cobalt atoms and iron atoms is 1:1;

[0053] S2. the grinding product of S1 is treated at a constant temperature to obtain a powdered high-dispersion cobalt-iron bimetallic catalyst,

[0054] Among them, the precursor salt in S1 is Co(NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 ·9H 2 O,

[0055] The temperature of constant temperature treatment in S2 is 500°C, the heating rate is 2°C / min, and the treatment time is 5h.

[0056] Wherein, the preparation method of uncalcined carrier SBA-15 is as follows:

[0057] S11. Prepare 1.6M hydrochloric acid solution, stir and dissolve 2g of P123 surfactant in 80mL of 1.6M hydrochloric acid solutio...

Embodiment 2

[0062] A preparation method of a highly dispersed cobalt-iron bimetallic catalyst, comprising the following steps:

[0063] S1. Weigh 1g of the prepared SBA-15 carrier in an agate mortar, add a precursor salt and grind for 30min, the precursor salt is 0.1497g Co(NO 3 ) 2 ·6H 2 O and 0.4618g Fe(NO 3 ) 3 ·9H 2 A mixture of O, the mass ratio of cobalt atoms and iron atoms is 1:2;

[0064] S2. the grinding product of S1 is treated at a constant temperature to obtain a powdered high-dispersion cobalt-iron bimetallic catalyst,

[0065] Among them, the precursor salt in S1 is Co(NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 ·9H 2 O,

[0066] The temperature of constant temperature treatment in S2 is 500°C, the heating rate is 2°C / min, and the treatment time is 5h.

[0067] Wherein, the preparation method of uncalcined carrier SBA-15 is as follows:

[0068] S11. Prepare 1.6M hydrochloric acid solution, stir and dissolve 2g of P123 surfactant in 80mL of 1.6M hydrochloric acid solutio...

Embodiment 3

[0072] A preparation method of a highly dispersed cobalt-iron bimetallic catalyst, comprising the following steps:

[0073] S1. Weigh 1g of the prepared SBA-15 carrier in an agate mortar, add a precursor salt and grind for 30min, the precursor salt is 0.0499g Co(NO 3 ) 2 ·6H 2 O and 0.4618g Fe(NO 3 ) 3 ·9H 2 A mixture of O, the mass ratio of cobalt atoms and iron atoms is 1:6;

[0074] S2. the grinding product of S1 is treated at a constant temperature to obtain a powdered high-dispersion cobalt-iron bimetallic catalyst,

[0075] Among them, the precursor salt in S1 is Co(NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 ·9H 2 O,

[0076] The temperature of constant temperature treatment in S2 is 500°C, the heating rate is 2°C / min, and the treatment time is 5h.

[0077] Wherein, the preparation method of uncalcined carrier SBA-15 is as follows:

[0078] S11. Prepare 1.6M hydrochloric acid solution, stir and dissolve 2g of P123 surfactant in 80mL of 1.6M hydrochloric acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com