Anti-vibration anti-loosening environment-resistant connector and cable assembly thereof

A connector and environment-resistant technology, which is applied to the parts of the connecting device, the connection, the protective grounding/shielding device of the connecting part, etc., and can solve problems such as fatigue damage of connector interconnected equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and technical effects adopted by the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

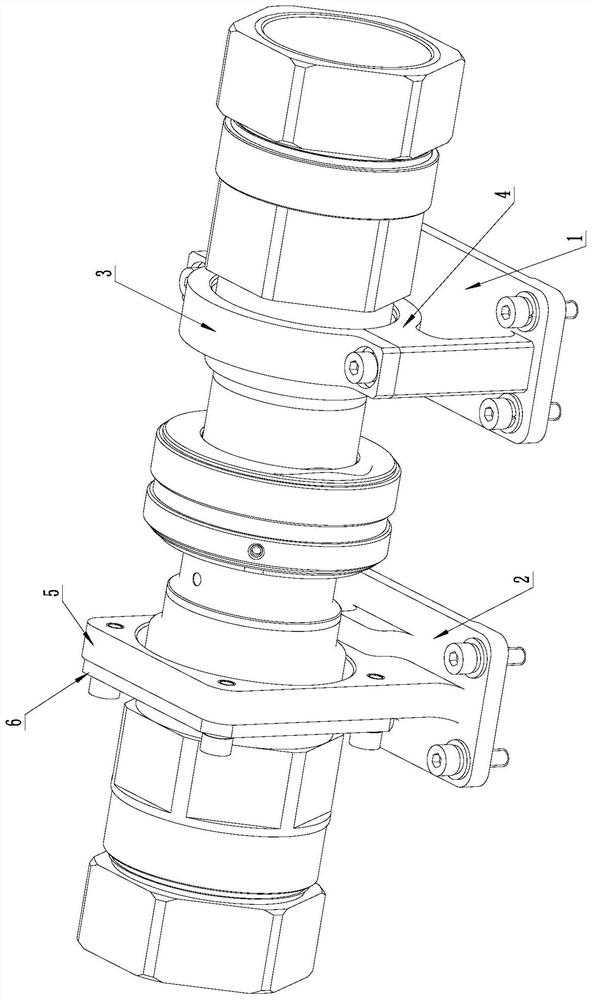

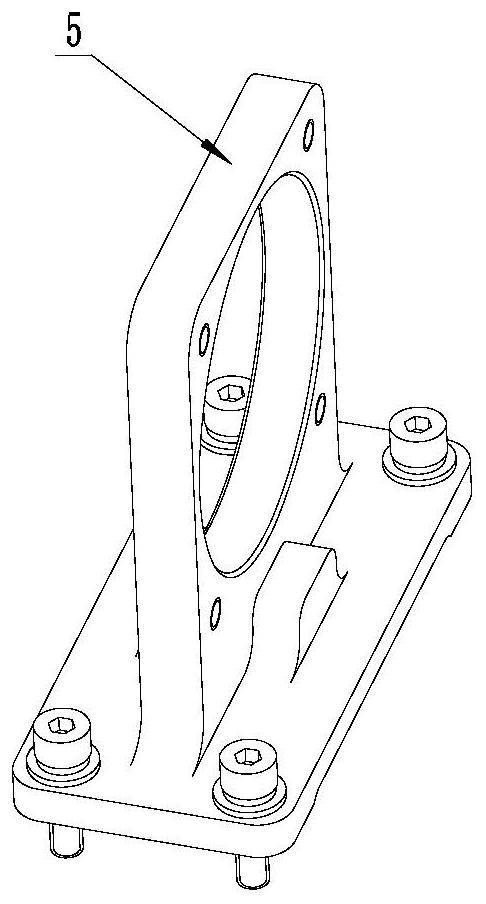

[0031] Such as figure 1 As shown, the connector of the present invention includes a plug, a socket, a floating support 1 and a fixed support 2 . An upper pressing plate 3 and a base 4 are connected to the floating support, and the plug is installed in the ring formed by the upper pressing plate and the base of the floating support, and is fastened by combination screws. The fixed support is provided with a fixed square plate 5, and the socket is provided with a corresponding mounting panel 6, and the mounting panel and the fixed square plate are fastened by combined screws so that the socket is fixed on the fixed support.

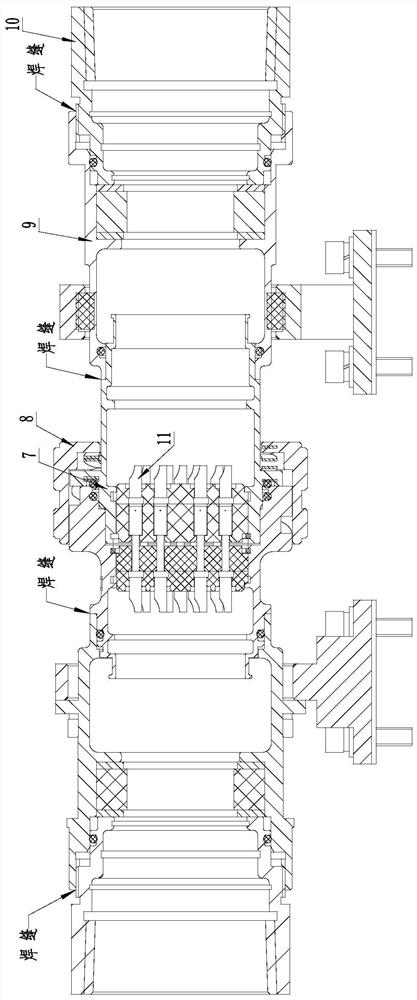

[0032] Specifically, such as Figure 5As shown, the plug includes a plug housing 7, a connecting nut 8, a round s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com