Non-Newtonian fluid cable and installation method thereof

A non-Newtonian fluid and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems affecting the outer sheath extrusion, transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

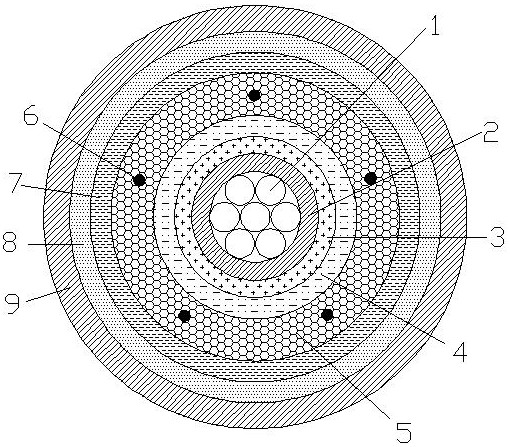

[0025] figure 1 The middle is a non-Newtonian fluid cable, in the figure: 1. wire, 2. reinforced fiber wrapping layer, 3. water blocking layer, 4. waterproof layer A, 5. polyvinyl alcohol particle layer, 6. heating resistance wire, 7. Waterproof layer B, 8. Heat insulation layer, 9. Sheath layer. including a cable core formed by twisting a plurality of wires;

[0026] The cable core is provided with a reinforcing fiber wrapping layer, the reinforcing fiber wrapping layer is provided with a water blocking layer, the water blocking layer is provided with a waterproof layer A, and the waterproof layer A is provided with polyethylene Alcohol particle layer, the polyvinyl alcohol particle layer is provided with a number of heating resistance wires, the polyvinyl alcohol particle is wrapped with water, and the polyvinyl alcohol particle is insoluble in water below 60 degrees Celsius, and the polyvinyl alcohol particle layer is equipped with There is a waterproof layer B, the water...

example 2

[0036] figure 1 The middle is a non-Newtonian fluid cable, in the figure: 1. wire, 2. reinforced fiber wrapping layer, 3. water blocking layer, 4. waterproof layer A, 5. polyvinyl alcohol particle layer, 6. heating resistance wire, 7. Waterproof layer B, 8. Heat insulation layer, 9. Sheath layer. including a cable core formed by twisting a plurality of wires;

[0037] The cable core is provided with a reinforcing fiber wrapping layer, the reinforcing fiber wrapping layer is provided with a water-blocking layer, the water-blocking layer is provided with a waterproof layer A, and the waterproof layer A is provided with polyethylene Alcohol particle layer, the polyvinyl alcohol particle layer is provided with a number of heating resistance wires, the polyvinyl alcohol particle is wrapped with water, and the polyvinyl alcohol particle is insoluble in water below 60 degrees Celsius, and the polyvinyl alcohol particle layer is equipped with There is a waterproof layer B, the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com