Cable conduction detection machine with compact structure

A compact, testing machine technology, used in electrical measurement, measurement devices, short-circuit testing, etc., can solve the problems of wasting raw materials, damaging cables, affecting production efficiency, etc., to increase the amount of contact, ensure stability, and improve the compact layout sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

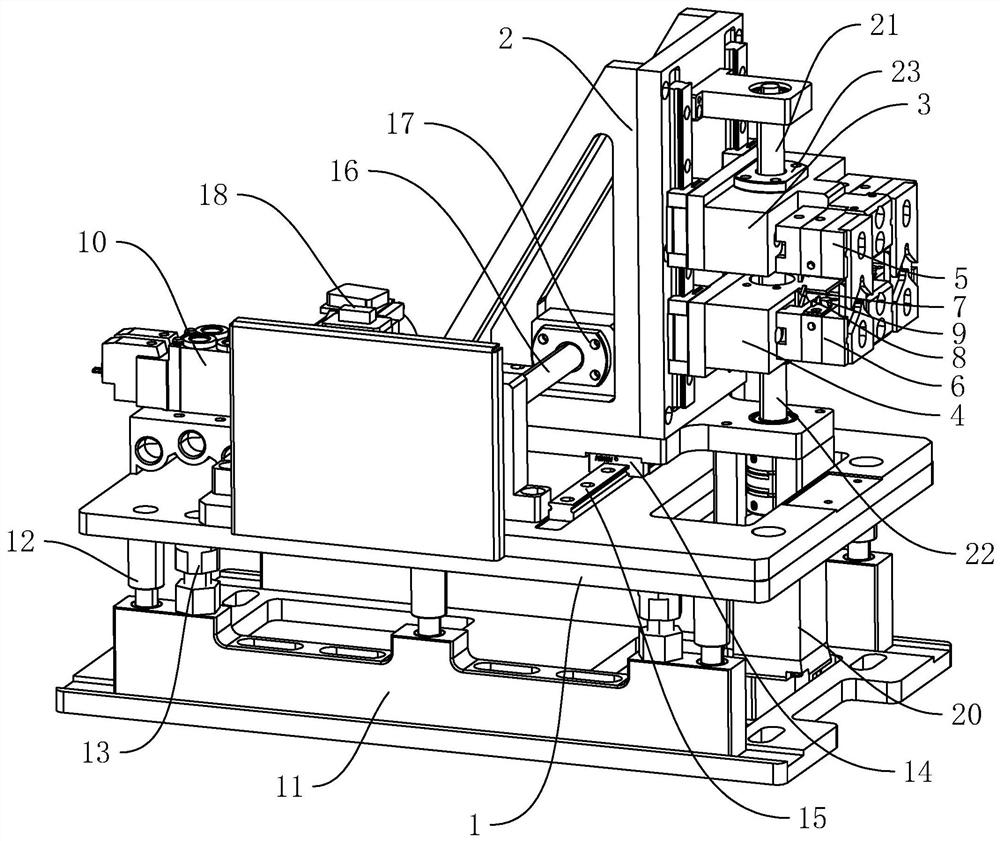

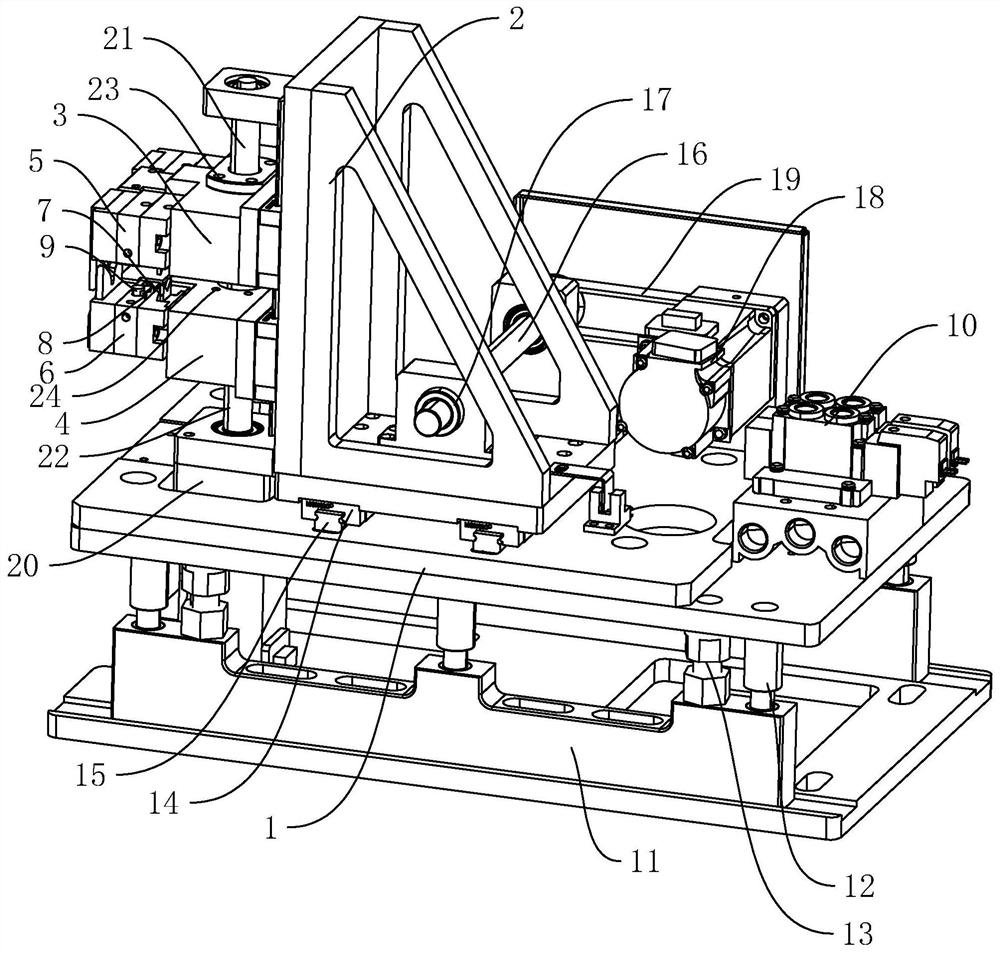

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

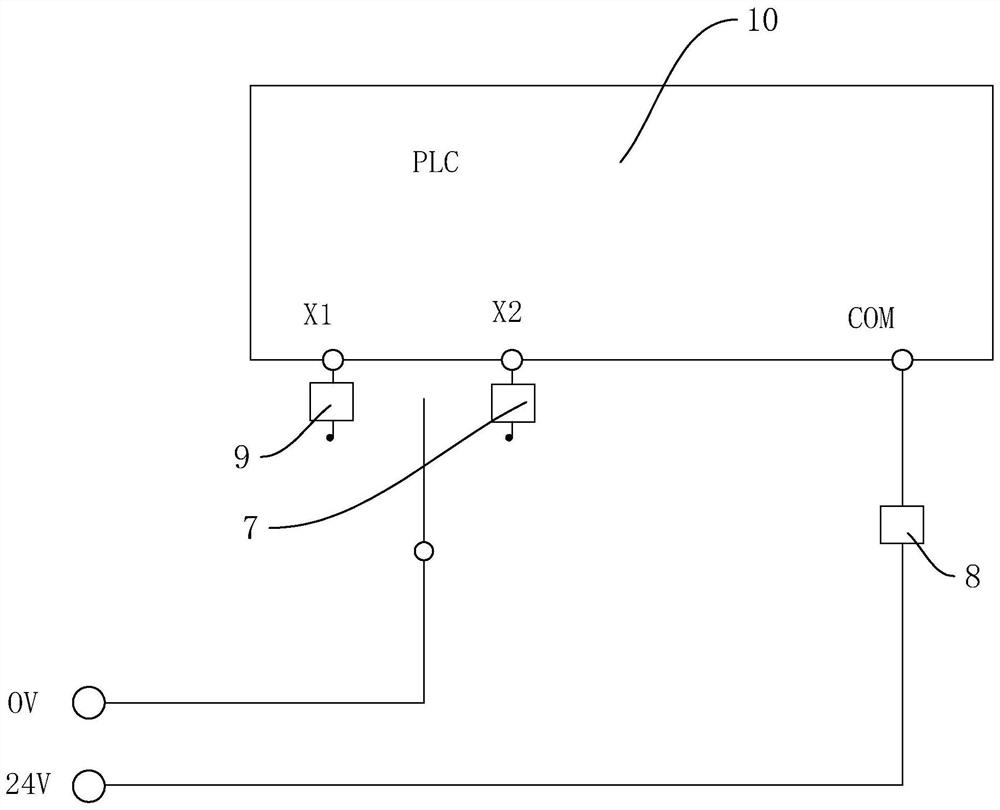

[0035] A compact cable continuity tester such as figure 1 , figure 2 As shown, it includes a mounting seat 1, a vertical frame 2 arranged on the mounting seat 1, an upper sliding seat 3 mounted on the vertical frame 2 for longitudinal sliding, and a lower sliding seat 4 opposite to the upper sliding seat 3. The vertical frame 2 is provided with a useful In order to drive the vertical drive assembly that drives the upper slide 3 and the lower slide 4 to approach and separate from each other, the upper slide 3 and the lower slide 4 are cooperatively provided with a multi-stage contact assembly, and the multi-stage contact assembly includes an upper contact assembly fixedly installed on the upper slide 3 The knife group mounting seat 5, and the lower knife group mounting seat 6 fixedly installed on the lower seat 4, the upper knife group mounting seat 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com