Electromagnetic chuck type friction limited slip differential

A limited-slip differential and differential technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of easy slippage, loss of traction, insufficient wheel adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

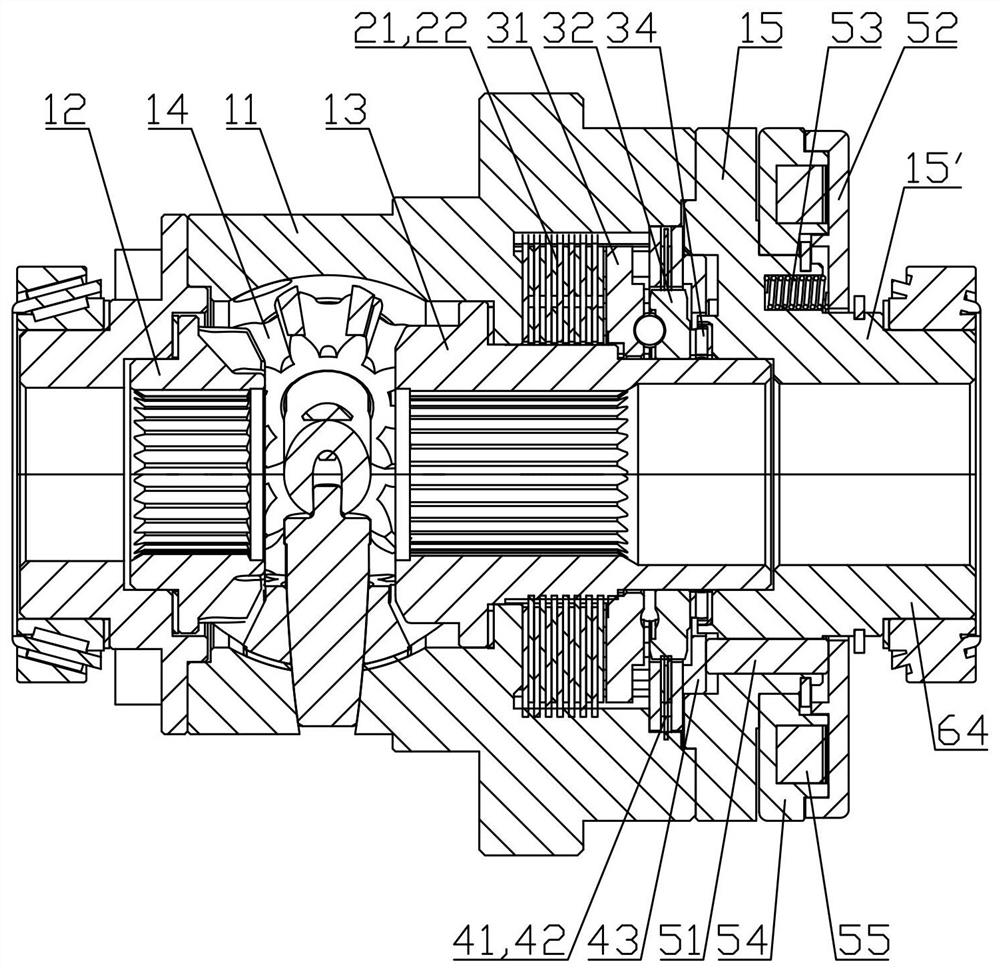

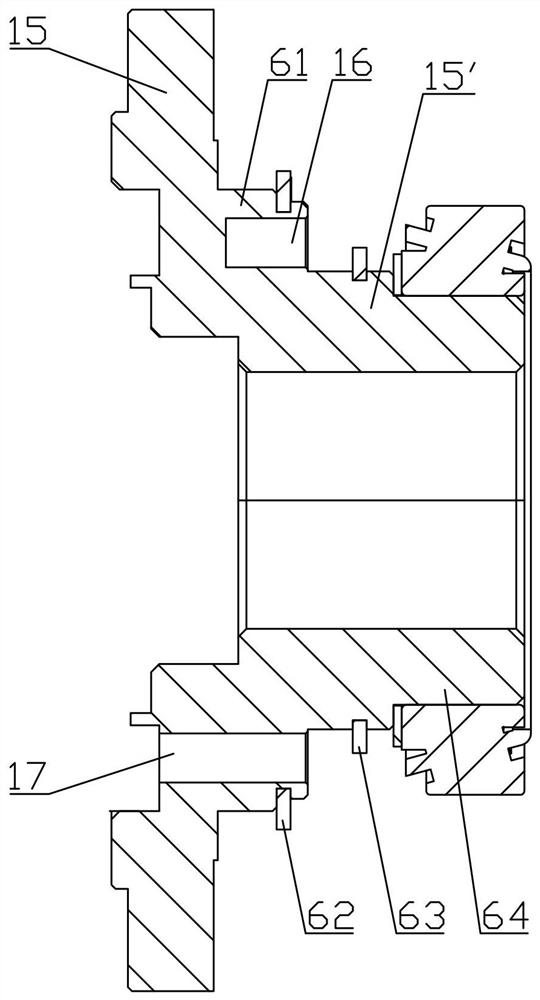

[0027] refer to figure 1, an electromagnetic chuck type friction limited-slip differential provided in this embodiment includes a differential housing 11, a left side gear 12, a right side gear 13, and simultaneously with the left and right side gears 12 and 13 respectively. The meshed planetary gear 14 also includes a limited-slip friction pair, a limited-slip actuator, a leading friction pair and a The right front actuation assembly. Wherein, the limited-slip friction pair has a plurality of first friction plates 21 connected to the differential case 11 and a plurality of second friction plates 22 connected to the right side gear 13, and the limited-slip actuator includes the first The relative rotation actuator of a cam plate 31 and the second cam plate 32, the leading friction pair has a plurality of third friction plates 41 connected to the differential case 11 and a plurality of third friction plates 41 connected to the second cam plate 32. The fourth friction plate 42...

Embodiment 2

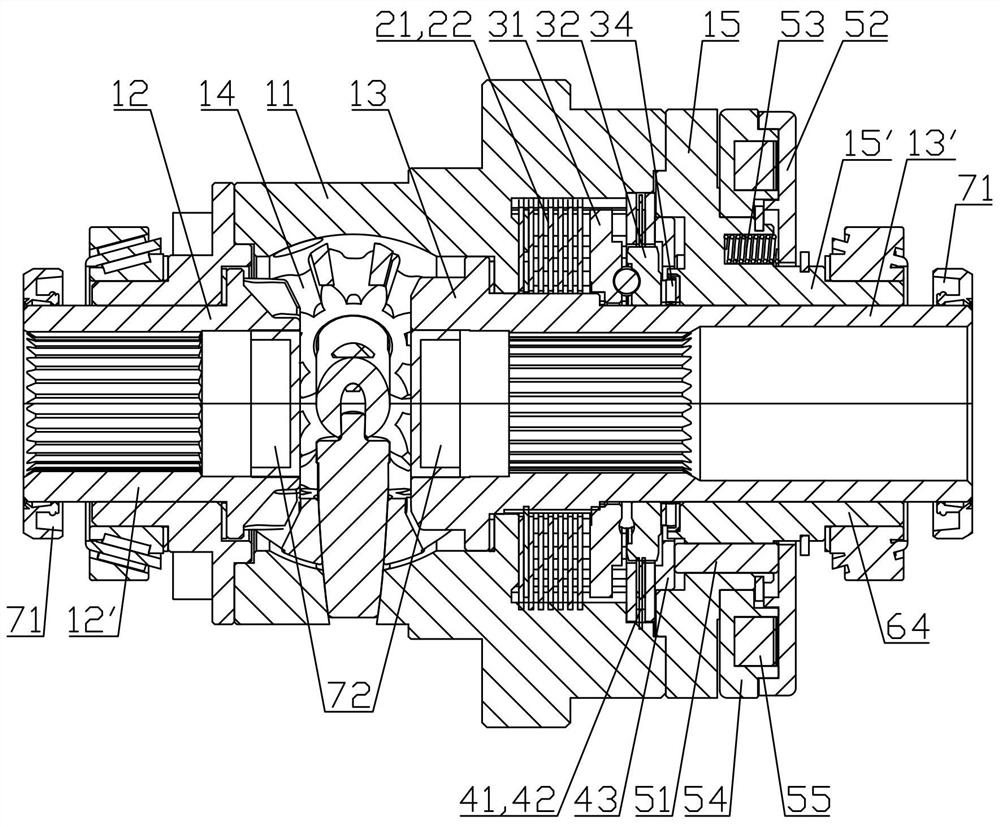

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: refer to image 3 , the left side shaft gear 12 and the right side shaft gear 13 are used to connect the shaft sleeve parts 12' and 13' of the left and right shaft shafts, and both extend axially outward and extend out of the differential case 11. The shaft sleeve part 12' , 13' protruding from the differential housing 11 through the oil seal 71 and the shaft holes at the two ends of the axle reduction box (not shown in the figure) are sealed and connected, and the shafts of the left and right side gears 12 and 13 Plugs 72 are sealingly connected to the inner ends, and a sealed cavity is formed between the plugs 72, the side gears 12, 13, the oil seal 71 and the reduction box. This structure forms a self-sealing when the left and right half shafts are not installed, so lubricating oil can be added without the half shafts being installed and the interior will not be pollute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com