Busy trunk line concrete sound barrier installation and construction method

A construction method and concrete technology, applied in the direction of noise absorption device, construction, etc., can solve the problems of difficult installation, lifting of concrete sound-absorbing panels, etc., and achieve the effects of improved construction efficiency, efficient and fast installation operations, and advanced technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] refer to Figure 1-Figure 12 , the installation and construction method of a concrete sound barrier for busy trunk lines described in the present invention will be described in detail.

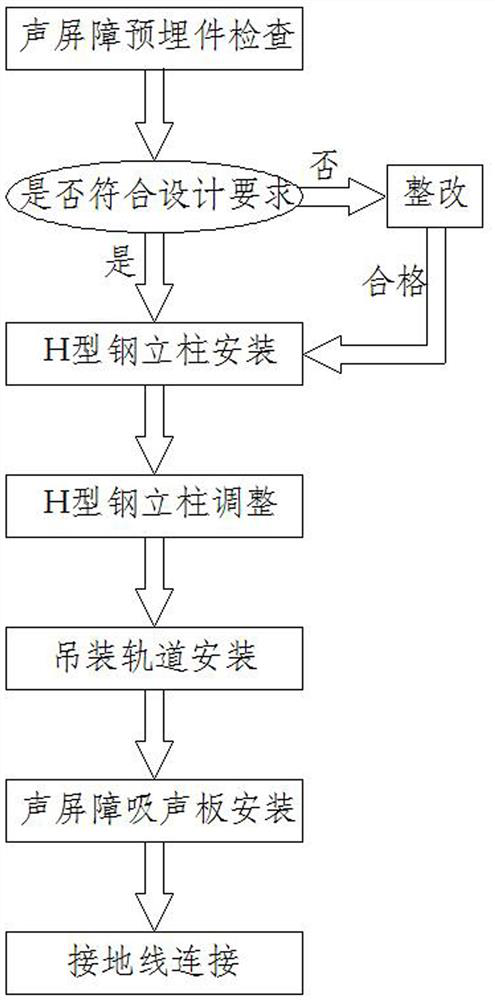

[0028] A construction method for installing a concrete sound barrier on a busy trunk line, comprising the following steps, the process is as follows: figure 1 Shown:

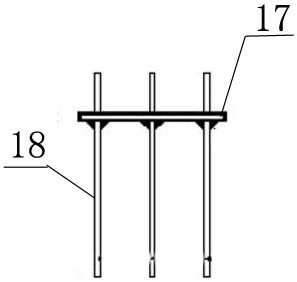

[0029] Step 1: Construct pile foundation 1 at the railway shoulder according to the design position, such as Figure 5 As shown, a number of H-shaped steel columns 3 arranged at intervals and parallel to each other are fixedly connected to the pile foundation 1 through the embedded parts 2, and the H-shaped steel columns 3 are located in the vertical direction, such as Figure 7 As shown; the H-shaped steel column 3 is made of H-shaped steel. According to the design requirements, the standard span of the adjacent embedded part 2 is 4m, and the error is -10~+20mm, because under normal circumstances, the length of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com