Current sharing control device and method for formation of corroded aluminum foil

A technology of corroding aluminum foil and flow control, which is applied in the field of electrode foil, can solve the problems of unstable current and voltage of the forming power supply, affecting the electrolytic formation of aluminum foil, and unstable voltage of the forming power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

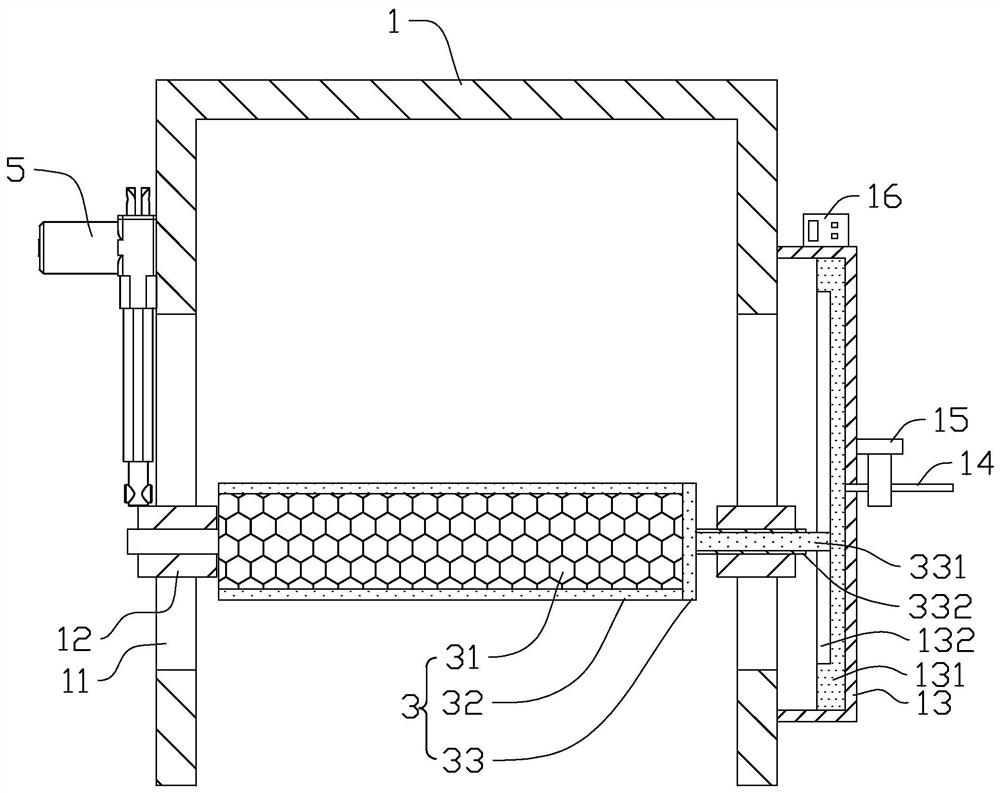

[0028] The following is attached Figure 1-4 The application is described in further detail.

[0029] The embodiment of the present application discloses a current sharing control device and method for forming corroded aluminum foil.

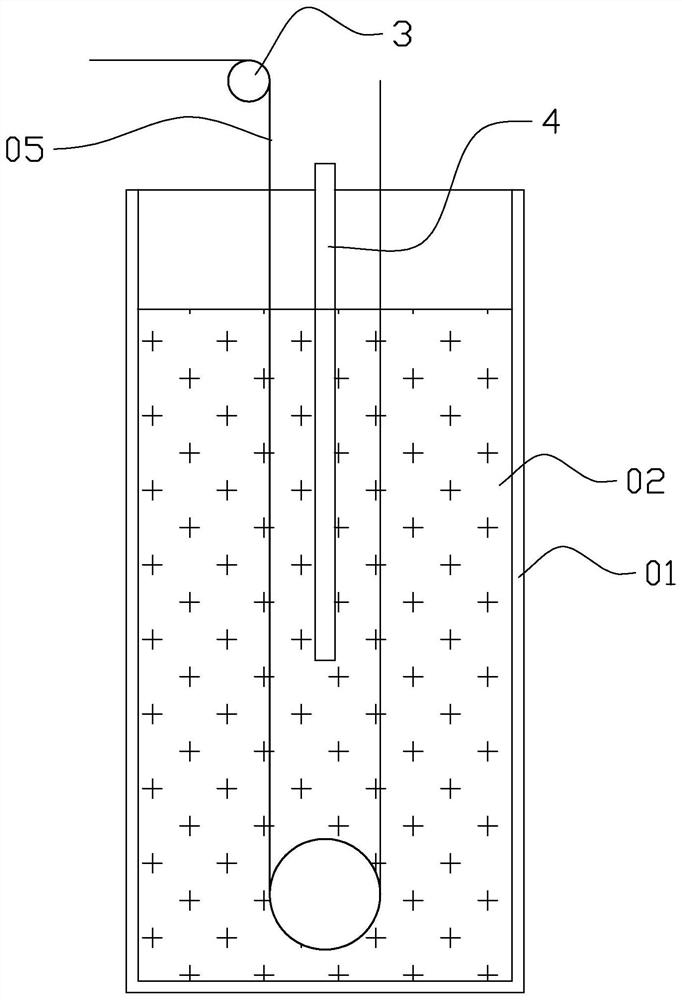

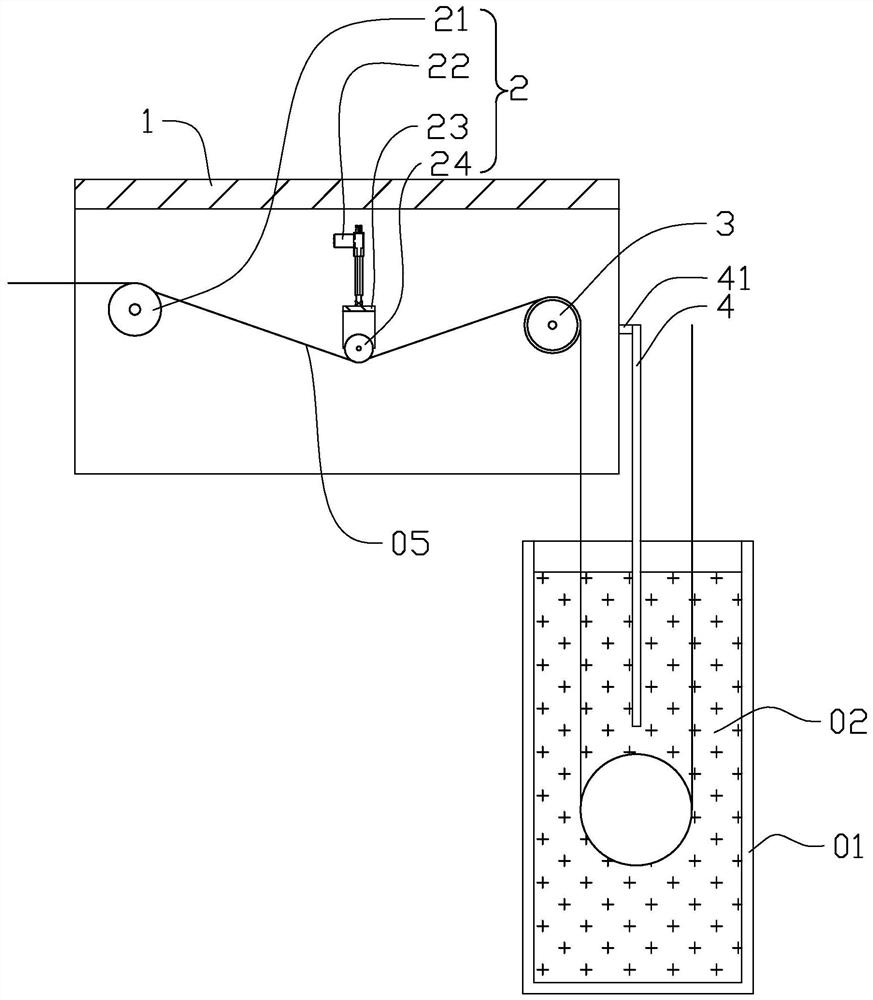

[0030] refer to figure 2 The current sharing control device for corroded aluminum foil formation includes a frame 1 arranged on the upper side of the formation tank 01, a guide assembly 2 arranged in sequence along the extending direction of the aluminum foil 05 passing through the frame 1, a conductive roller 3 and a conductive frame 4. The frame 1 is a plate-like structure with an inverted U-shaped cross section, and its length direction is horizontal, and the aluminum foil 05 passes through the frame 1 before entering the formation tank 01 . The conductive frame 4 is in the shape of a rectangular plate and is made of copper. An insulating block 41 is fixedly connected between its upper end and the end of the frame 1 close to the formation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com