Integrated breeding sewage treatment device with microbial fermentation pretreatment

A technology for microbial fermentation and aquaculture sewage, which is applied in the field of sewage treatment equipment and integrated aquaculture sewage treatment equipment, and can solve the problems of filter layer blockage, backflow, and waste liquid that cannot be fermented and processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

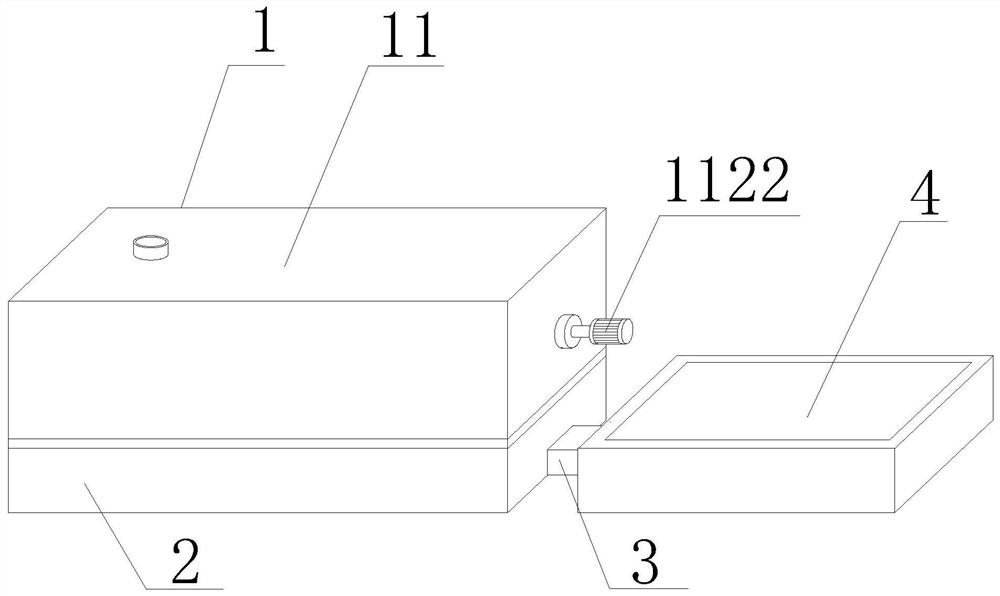

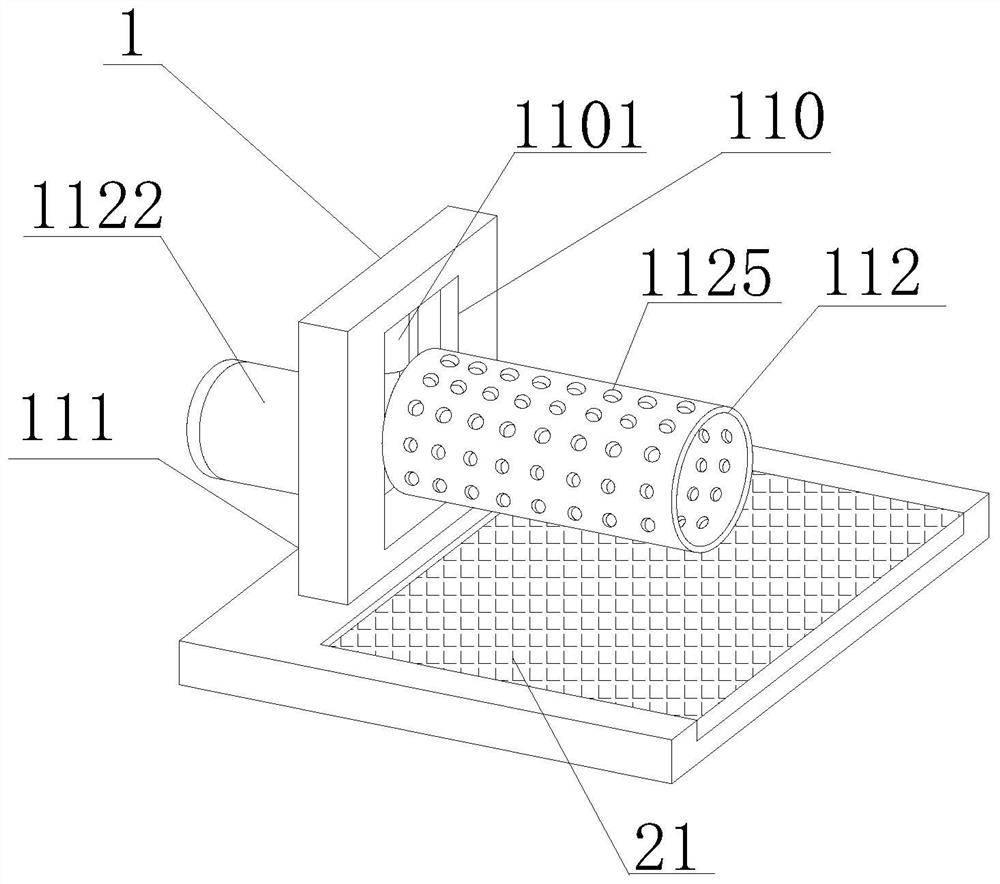

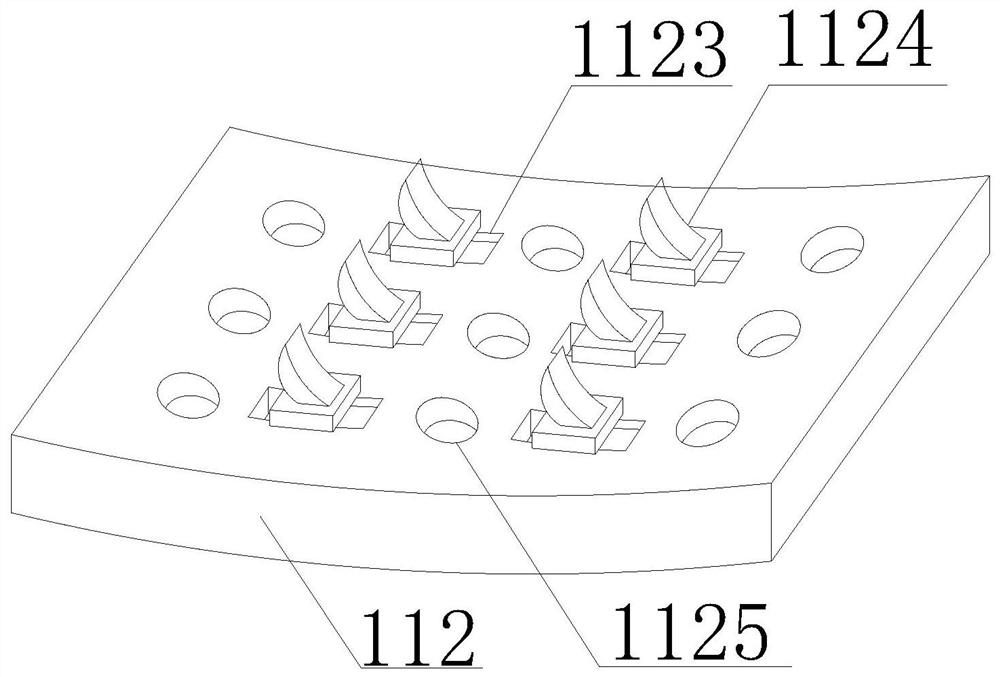

[0044] Such as Figure 1-8As shown, the present invention provides an integrated aquaculture sewage treatment device with microbial fermentation pretreatment, comprising a sewage treatment tank 1, a sedimentation chamber 2, an injection pipe 3 and a fermentation chamber 4, and the interior of the sewage treatment tank 1 is fixedly installed with a filter chamber 11, the bottom of the filtration chamber 11 is fixedly equipped with a precipitation chamber 2, the side of the precipitation chamber 2 is fixedly connected with an injection pipe 3, and the side of the injection pipe 3 away from the precipitation chamber 2 is fixedly installed with a fermentation chamber 4, and the inside of the filtration chamber 11 is fixed A rotating device 111 is installed, and a flow blocking device 31 is fixedly installed on the outside of the injection pipe 3. The rotating device 111 includes a rotating tube 112, and a push block 1121 is fixedly installed on the side of the rotating tube 112, an...

Embodiment 2

[0047] Such as Figure 1-8 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, the top of sedimentation chamber 2 is fixedly installed with filter layer 21, and the bottom of sedimentation chamber 2 is fixedly installed with sedimentation plate 22, and the bottom of sedimentation chamber 2 is fixedly installed with sedimentation plate 22, and A sedimentation block 221 is fixedly installed on the top, and a blocking column 222 is arranged on the surface of the precipitation block 221 , and a particle block 223 is fixedly installed on the surface of the blocking column 222 .

[0048] In this embodiment, the sedimentation plate 22 is installed through the bottom of the sedimentation chamber 2, so that the filtered liquid is deposited in the sedimentation chamber 2 to the sedimentation plate 22, and then the blocking column 222 and the particle block 223 cooperate with each other, thereby increasing the stability of the sedime...

Embodiment 3

[0050] Such as Figure 1-8 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the blocking device 31 includes a heating tube 311, the inner side of the heating tube 311 is fixedly sleeved on the outside of the injection tube 3, and the inner wall of the injection tube 3 A baffle 312 is fixedly installed on the top of the baffle 312, a stopper 3121 is fixedly installed at the bottom of the baffle 312, a stopper hole 3122 is fixedly installed on the side of the stopper 3121, a heating layer 3111 is fixedly installed inside the heating tube 311, and the heating tube 311 A power board 3112 is fixedly installed on the bottom of the heating layer 3111, a heating block 3113 is fixedly installed inside the heating layer 3111, and a heating net 3114 is fixedly installed on the side of the heating block 3113.

[0051] In this embodiment, the injection pipe 3 is U-shaped, so that the liquid is injected lower than the injection port, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com