A self-contained waterproof zipper

A technology of waterproof layer and waterproof chain piece, applied in the field of zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

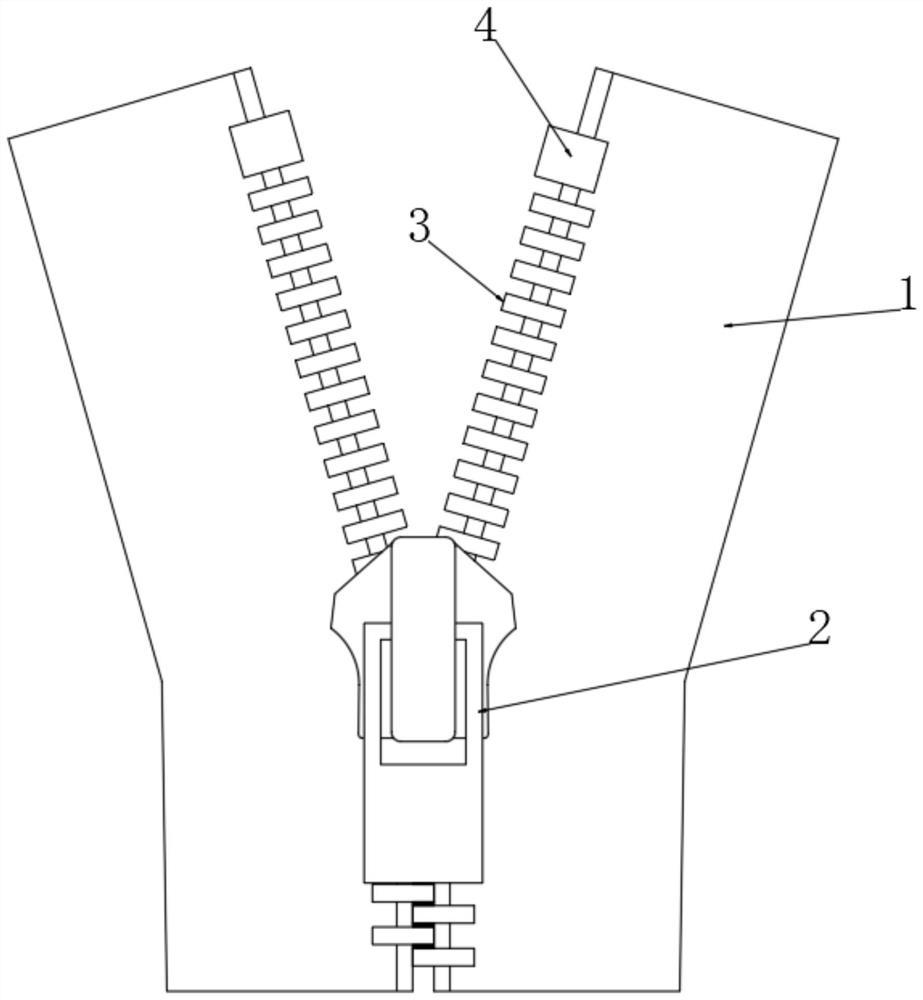

[0043] see figure 1 , a self-contained waterproof layer zipper, comprising two waterproof links 1, two sets of sprockets 3 respectively installed on the two waterproof links 1, and a zipper head 2 connected to the two sets of sprockets 3, adjacent to each other. The two sets of sprockets 3 are dislocated and meshed with each other, and a positioning block 4 is arranged above the two sets of sprockets 3 , and the positioning block 4 is fixedly connected with the waterproof chain piece 1 .

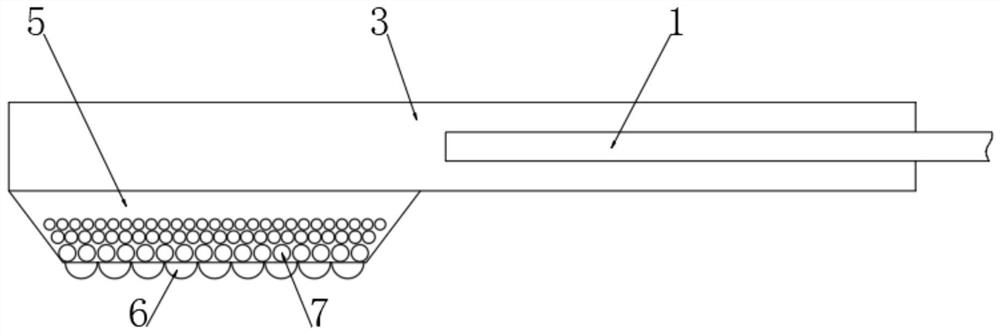

[0044] see Figure 2-3 , the lower end of the sprocket 3 located outside the waterproof chain piece 1 is fixedly connected with an externally variable magnetic capsule 5, and the externally variable magnetic capsule 5 is filled with gas powder, and the gas powder includes graphene powder and compressed air, and the compressed air The multiple is not less than 2 times, so that the externally variable magnetic capsule 5 is in a full state and has a certain hardness. When the externally variab...

Embodiment 2

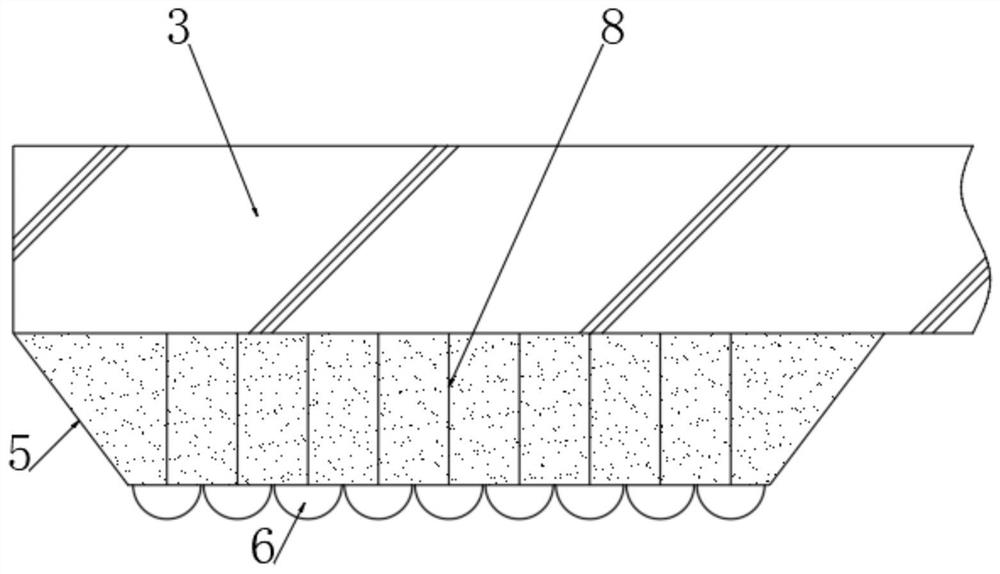

[0050] see Figure 8 , The main difference between this embodiment and Embodiment 1 is: the inner control piece 8 is composed of two arcuate shrapnel whose longitudinal vertices are relatively far away, which has strong resilience. When the zipper is opened through the zipper head 2, its The resilience is convenient for the externally variable magnetic capsule 5 to quickly recover and deform, and the air compression ratio is not higher than 1.5 times, so that the externally variable magnetic capsule 5 has a relatively low strength compared with Example 1 in a natural state, making it difficult to cause the formation of The waterproof layer is accidentally separated, thereby effectively ensuring the stability of the waterproof layer, so that the waterproof effect of the zipper is better. Saturated filling makes the adsorption force between the two adjacent externally variable magnetic capsules 5 larger, makes the connection tightness of the waterproof layer higher, and effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com