A kind of automatic system and method for lysine production and crystallization extraction

An automated system and lysine technology, applied in the field of lysine processing equipment, can solve the problems of re-fusion of crystal and solution, cumbersome process, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

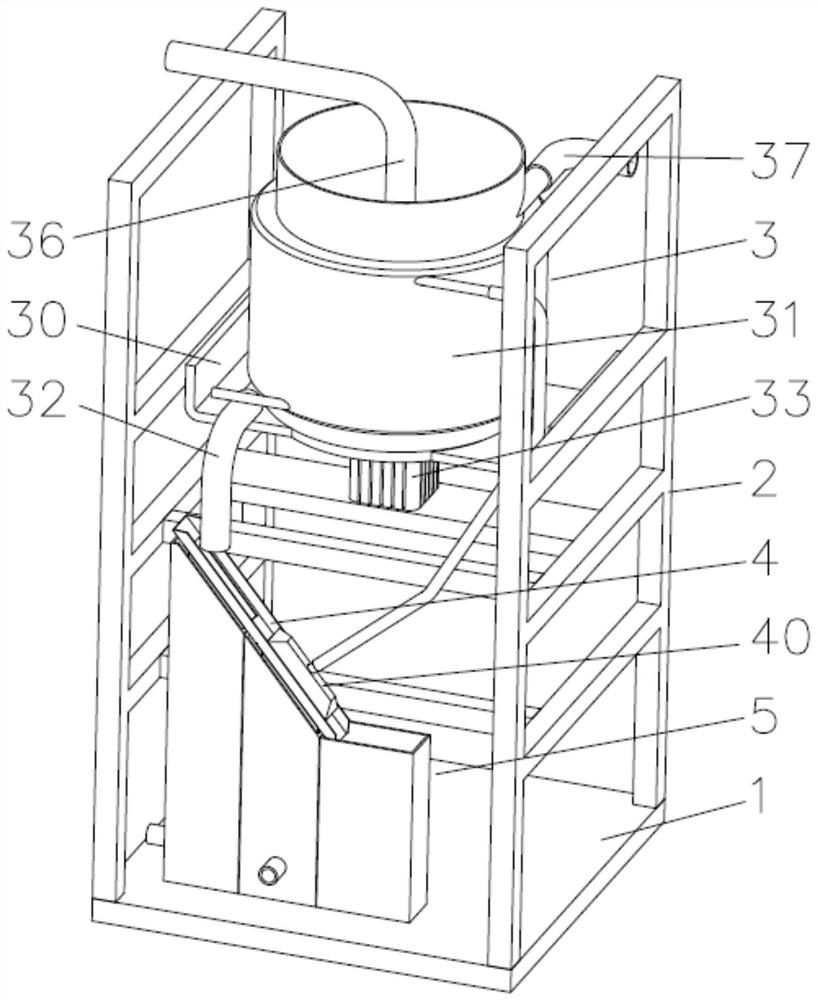

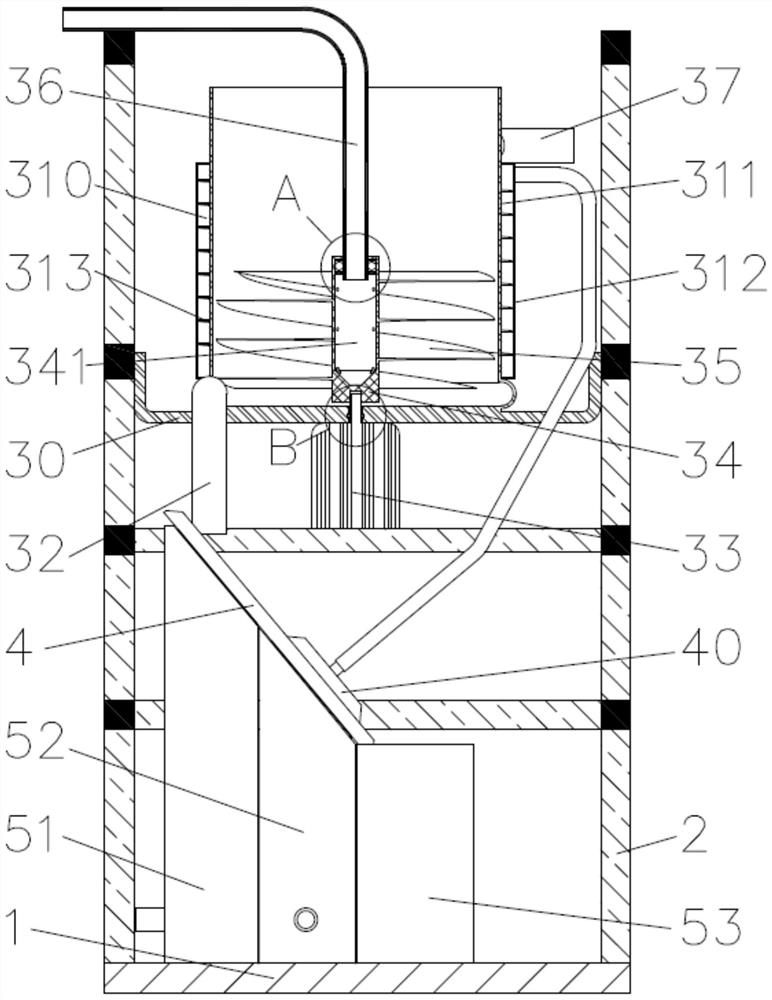

[0038] Such as Figure 1-7 As shown, an automated system for lysine production and crystallization extraction is characterized in that: it includes a base 1, a support 2, a cooling separation assembly 3, a feed trough 4 and a liquid collector assembly 5, and the upper end surface of the base 1 and the support 2. The bottom is fixedly connected, and the cooling separation component 3 is fixedly arranged on the bracket 2;

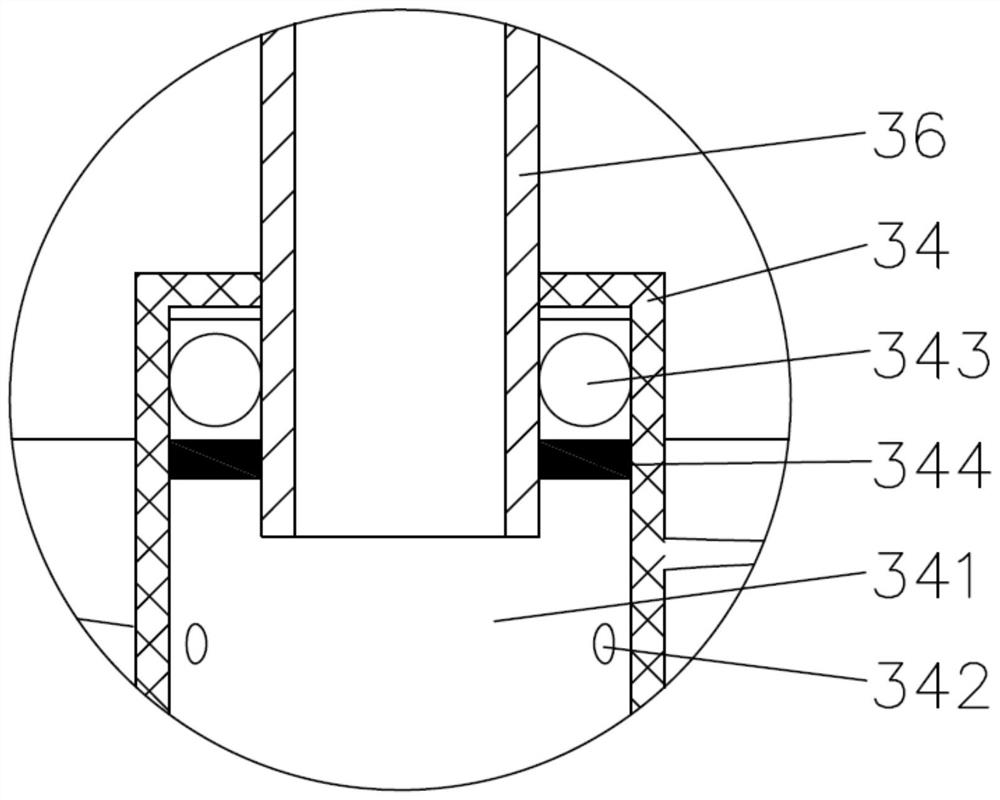

[0039] The cooling separation assembly 3 comprises a cooling separation tank 31, a discharge pipe 32, a drive motor 33, a rotating shaft 34, a separation blade 35, and a feed pipe 36; The tank 31 is a double-layer structure, including a cooling inner wall 311 and a thermal insulation outer wall 312. A cooling cavity 310 is formed between the cooling inner wall 311 and the thermal insulation outer wall 312. A spiral deflector 313 is arranged in the cooling cavity 310 and the middle of the spiral deflector 313 The axis is collinear with the central axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com