Working method of experiment system for bridge

A technology of experimental system and working method, which is applied in the field of bridge experimental system, can solve problems such as difficulty in processing, difficulty in processing and installation of sealing structure, and influence on effect, and achieve a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

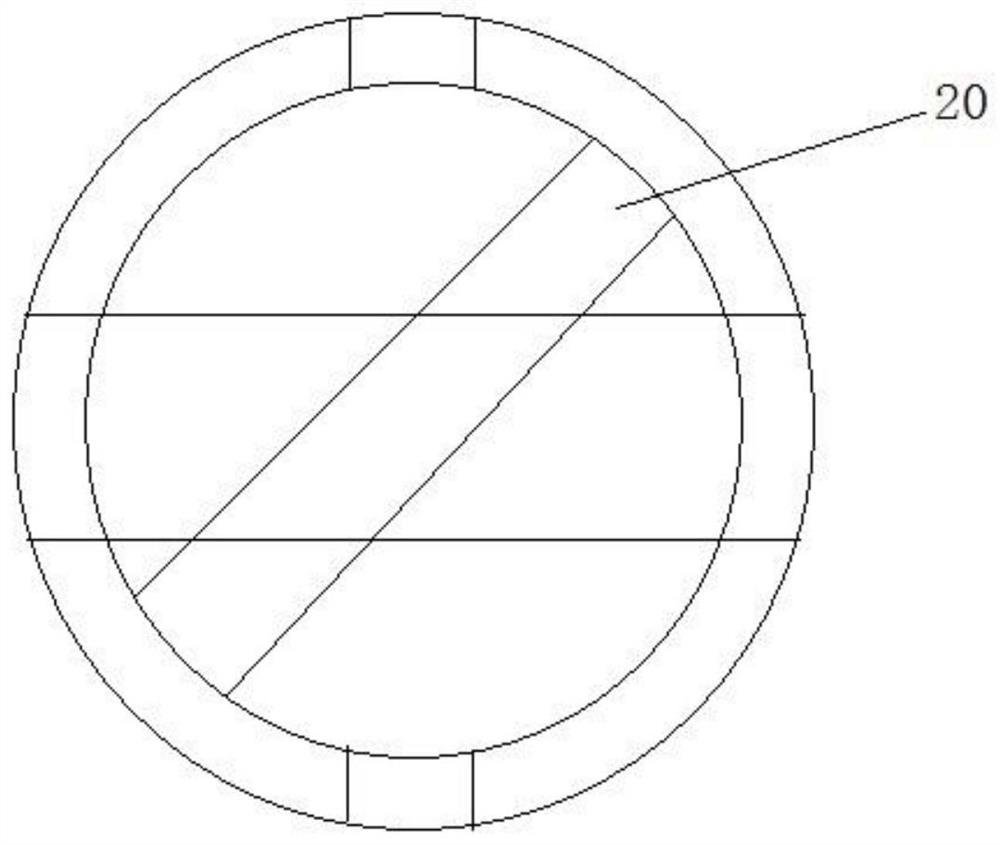

[0055] As shown in the figure: a working method of an experimental system for a bridge, including a fan, an air suction port, an air blowing port, a control valve, an air filter, a main girder section model, and a control unit; wherein the main girder section model includes Edge, main beam section, suction port, suction pipeline, blowing port, external port 1, external port 2, blowing pipeline, acceleration sensor, anemometer, flow meter, the fan sucks air through the suction port, The air filter is connected through the blowing port, the output end of the air filter is connected to the control valve, and the output air of the control valve is blown to the edge of the main beam segment model, and the main beam section is provided with There are an external port 1 and an external port 2. The external port 1 is connected to an external blowing device, and the external port 2 is connected to an external suction device. The edge is provided with a suction port and a blowing port. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com