Maintenance-free high-pressure-difference gas-phase medium valve system

A high pressure difference, maintenance-free technology, applied in the direction of valve details, valve devices, valve housing structure, etc., can solve the problems of steam leakage, valve and pipe wall damage, etc., to reduce the medium flow rate, ensure stable operation, and avoid erosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] See Figure 1 ~ 3 One-free high-pressure differential gas phase medium valve system, including high pressure difference valve 1, Raval tube 2, and shrink tube 3, characterized in that one end of the high pressure difference valve is fixedly mounted to mount the Lavar tube 2, the pull The Wal Tube 2 is fixedly mounted from one end of the high pressure difference valve 1, wherein the high pressure difference valve 1, the Lavar tube 2 and the shrink tube 3 are connected by the flange.

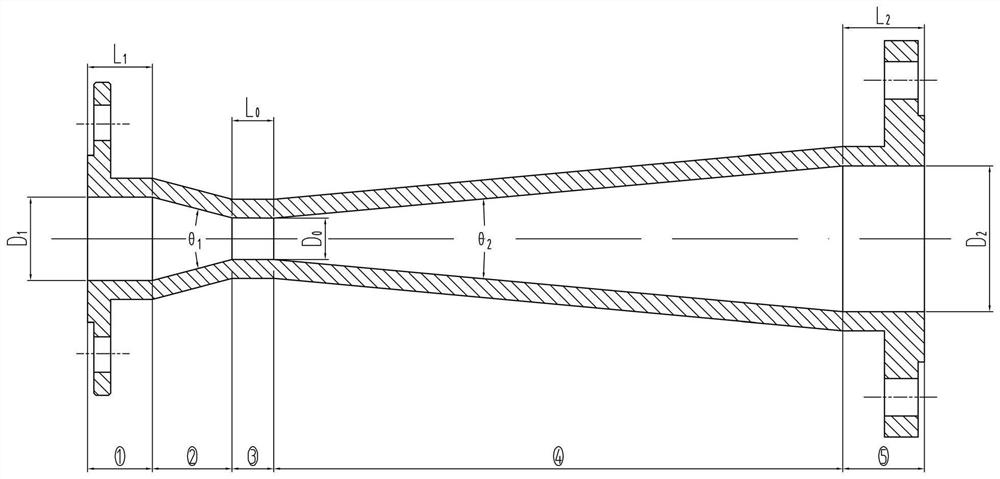

[0020] Depend on figure 2 It can be seen that the Lavar tube 2 is composed of a shrinkage section, a Raval tube balance section, a Raval tube diffusion section, and a Raval tube outlet, by calculating the determination of the Dalvar inlet diameter D. 1 , Inlet length L 1 , Throat diameter D 0 , Export diameter D 2 , Shrink angle θ 1 , Diffusion angle θ 2 , Balancing tube length L 0 And Raval outlet length L 2 .

[0021] Depend on image 3 It can be seen that the shrink tube 3 is composed of a shr...

Embodiment 2

[0024] Example 2, based on the above-described Embodiment 1, the various components of this design can be adjusted, thereby applies to high temperature high pressure differential gas phase media valves under different conditions of industrial production units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com