Self-tie steel-wood combined joint and mounting method

A technology of steel-wood combination and joints, which is applied in the direction of architecture and building construction, can solve problems such as no recovery ability, small parts are easy to break, and complex connections, so as to avoid large deformation and damage, improve integrity and energy consumption capacity , Improve the effect of the overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

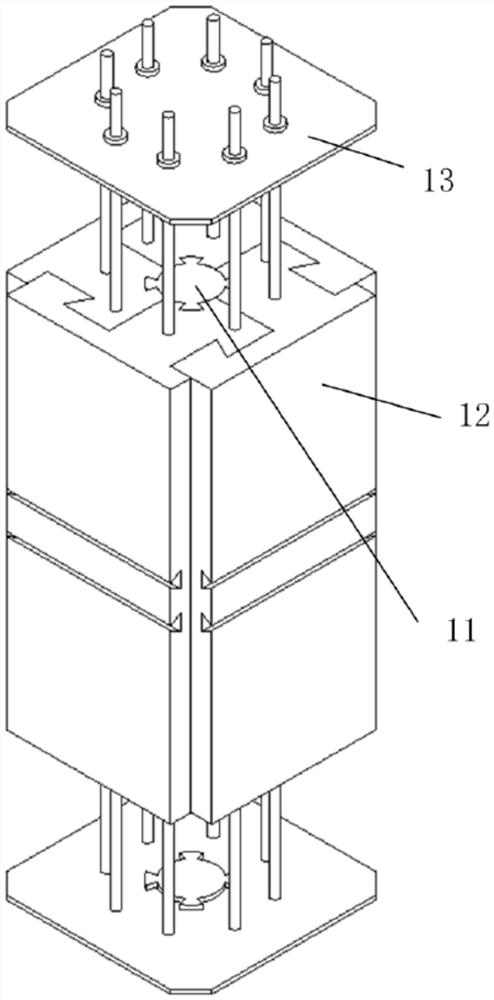

[0052] Such as figure 1 As shown, the self-tensioning steel-wood composite node of this embodiment includes a self-tensioning composite column 1 , a composite beam 2 and a beam-column reinforcement kit 3 .

[0053] Such as figure 2 As shown, the self-tie composite column includes a central column 11 and four peripheral tie columns 12 located outside the central column 11. The two adjacent peripheral tie columns are connected by mortise and tenon, and the central column and its outer periphery The mortise and tenon connection of the pull knot column forms a square column.

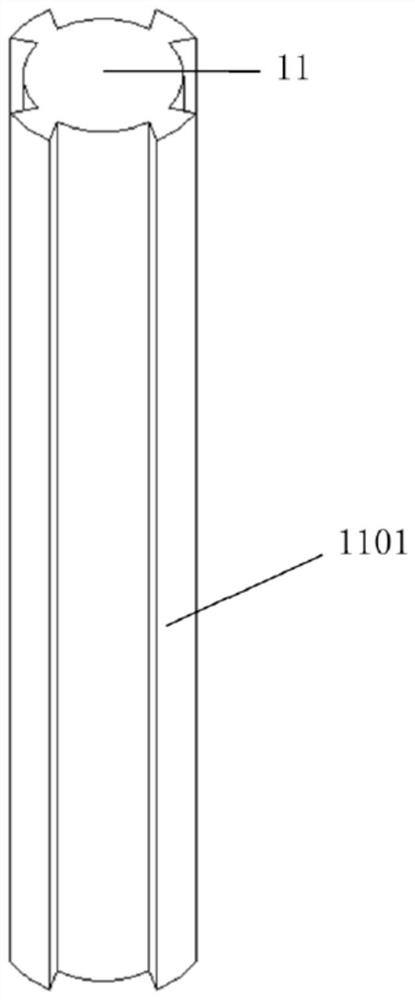

[0054] Such as image 3 As shown, four dovetail-shaped tenons 1101 are evenly distributed on the central column 11 along the circumference of the column, and the dovetail-shaped tenons 1101 are integrated with the central column 11 and have the same height.

[0055] Such as Figure 4 to Figure 6As shown, the cross-section of the peripheral tie column 12 is L-shaped, including the horizontal short side 1...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 is that the composite beam and the self-tensioning composite column are connected through the beam-column connection block 4, such as Figure 12 As shown, a horizontal tenon 41 is provided on one side of the beam-column connection block 4 , horizontal sockets 42 are provided at the upper and lower ends of the corresponding other side, and vertical tenons 43 are provided between the horizontal sockets.

[0069] In this embodiment, since the composite beam 2 is connected with the beam-column connecting block 4, the structure of the composite beam 2 is also changed, as Figure 13 As shown, there is a vertical mortise 2202 at the front end of the web, and the mortise on the inner side of the flange plate and the mortise 2201 on the top and bottom of the web do not run through the entire length, but are short.

[0070] When connecting, first insert the horizontal mortise 41 of the beam-column connecting block 4 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com