Efficient desilting device with good cleaning effect for hydraulic engineering

A water conservancy project and dredging device technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as poor crushing effect, pipeline blockage, and poor use effect, and achieve Improve crushing efficiency, facilitate repair and maintenance, and facilitate mud cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

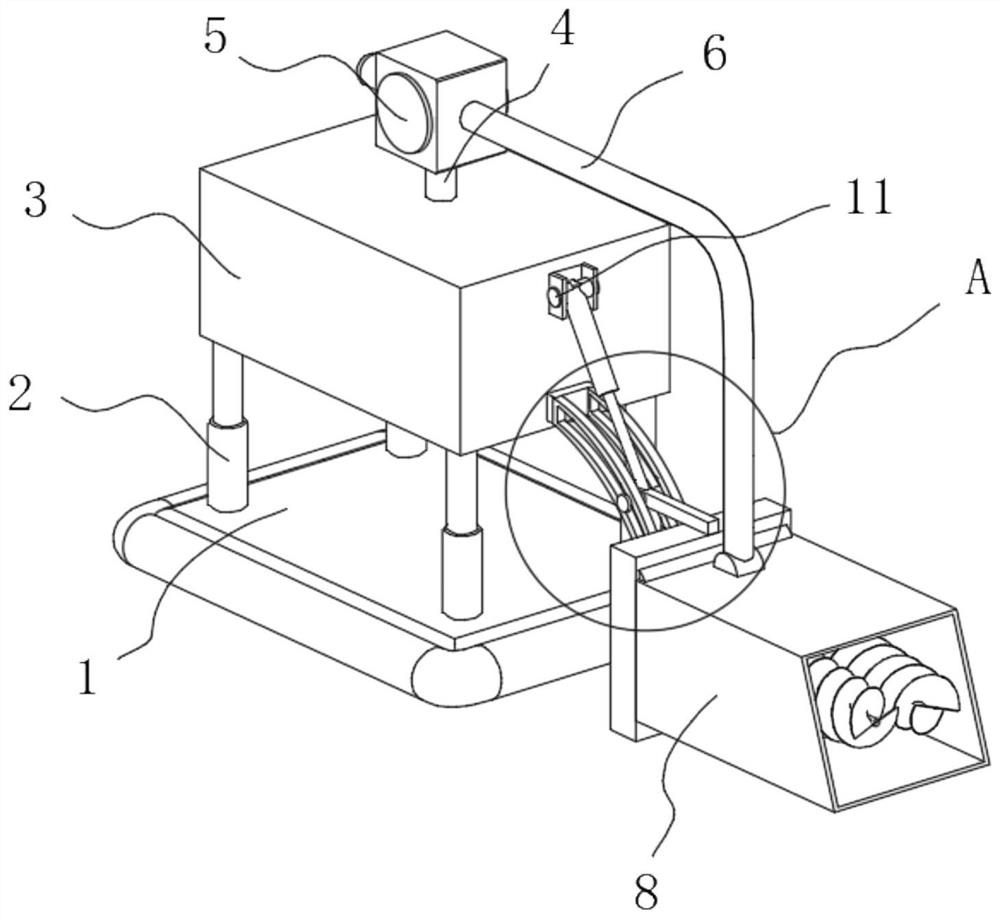

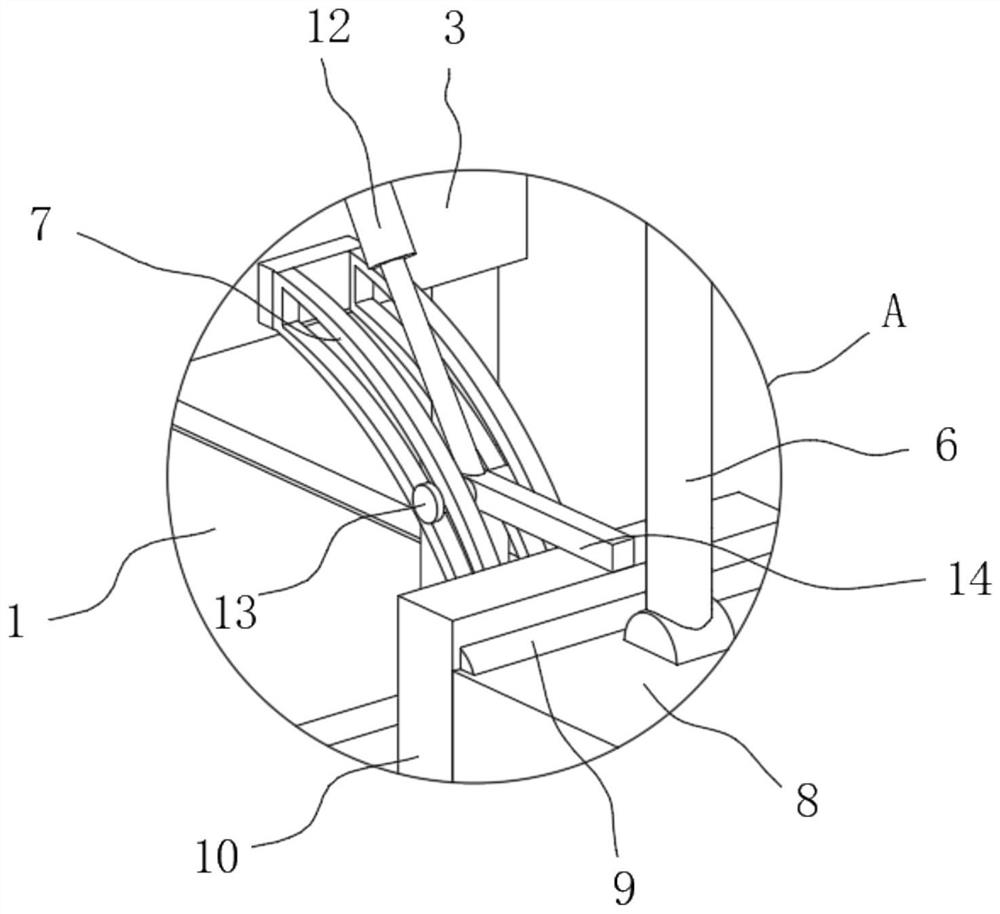

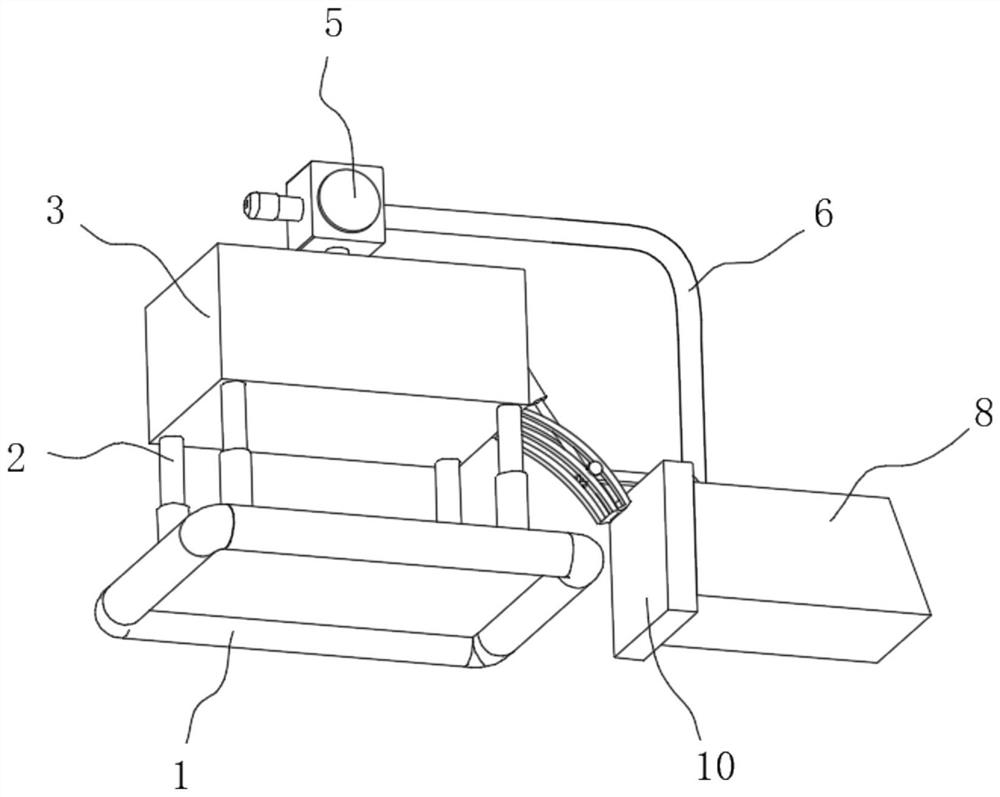

[0030] see Figure 1-7, the present invention provides a technical solution: a high-efficiency dredging device with good cleaning effect for water conservancy projects, comprising a floating plate 1, the four corners of the top of the floating plate 1 are fixedly connected with a hydraulic cylinder 2, and the top of the hydraulic cylinder 2 is fixedly connected with a The mud storage box 3, the top of the mud storage box 3 is fixedly connected with the mud inlet pipe 4, the top of the mud inlet pipe 4 is fixedly connected with the dredging pump 5, and one side of the mud pump 5 is fixedly connected with the connecting pipe 6, the connecting pipe 6 A mud scraper 8 is hinged at the bottom of the mud scraper 8, and a dismounting device 9 is provided on one side of the mud scraper 8. The dismounting device 9 includes a concave groove 901, and a convex block 902 is clamped on the inner wall of one side of the concave groove 901. The convex block The inside of 902 is connected with ...

Embodiment 2

[0033] see Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the driving mechanism 10 includes a driving box 1001, the top inner wall of the driving box 1001 is fixedly connected with a hydraulic part 1002, and the bottom of the hydraulic part 1002 is fixedly connected with a gear plate 1003, one side of the gear plate 1003 is meshed with a gear one 1004, one side of the gear one 1004 is fixedly connected with a drive rod one 1005, one side of the drive rod one 1005 is rotatably connected with a movable seat one 1006, and the gear plate 1003 is far away from the gear one 1004 One side of gear two 1007 is meshed with gear two 1007, one side of gear two 1007 is fixedly connected with drive rod two 1008, one side of drive rod two 1008 is rotatably connected with movable seat two 1009, and the outer wall of drive rod one 1005 is fixedly connected with broken blades One 1010, the outer wall of the drive rod two 1008 is fixedly ...

Embodiment 3

[0036] see Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: one side of the outer wall of the mud storage box 3 is fixedly connected with an arc-shaped frame 7, and one side of the mud scraper 8 is passed through a disassembly device 9. A driving mechanism 10 is fixedly connected. One side of the outer wall of the mud storage box 3 is fixedly connected with a hinged support 11. One side of the hinged support 11 is hinged with a moving cylinder 12. The bottom of the moving cylinder 12 is fixedly connected with an H-shaped sliding column 13. One side of the H-shaped slid 13 is fixedly connected with a connecting rod 14, and one side of the arc-shaped frame 7 is provided with an arc-shaped hole that is compatible with the H-shaped slid 13, and the inner wall of the arc-shaped hole is connected with the H-shaped slid 13. The outer wall of the connecting rod 14 is fixedly connected to the top outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com