Anti-adhesion hydrophobic coating formula for pipette tip and preparation process

A hydrophobic coating and anti-adhesion technology, applied in the coating and other directions, can solve the problems of reducing the accuracy of test results, affecting the accuracy of reagents, etc., to meet the needs of mass production, the production process is simple and convenient, and the effect of reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

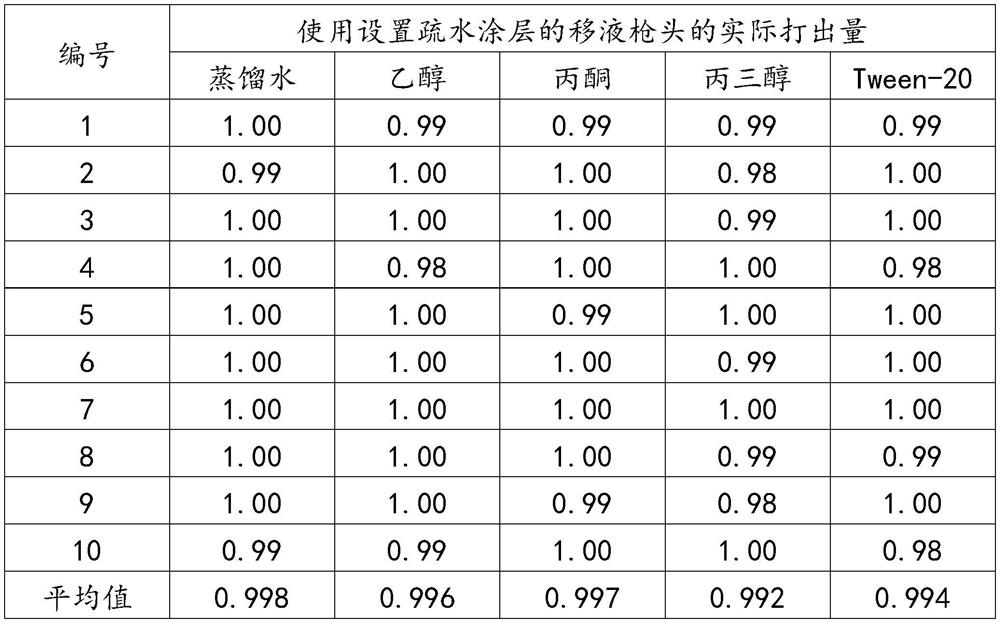

Examples

Embodiment

[0023] An anti-adhesion hydrophobic coating formula for a pipette tip, which consists of the following components by weight fraction: 20-35 parts of nano silicon dioxide, 25-40 parts of fluorosilane, and 8-12 parts of polyvinyl alcohol nano-microspheres , 5-20 parts of fixative, 2-4 parts of defoamer, 20-35 parts of solvent.

[0024] Specifically, silicon fluoride is one of tridecafluorooctyltriethoxysilane and perfluorodecyltriethoxysilane, the particle size of polyvinyl alcohol nanospheres is 0.5-0.8 μm, and the curing agent is One of polyamide, phenolic modified amine and epoxy resin, the defoamer is a combination of one or more of alkyl silicone oil, alcohols and oleic acid, the solvent is absolute ethanol, n-propanol, iso A combination of one or more of propanol, acetone, tetrahydrofuran, N, N-dimethylacetamide, N, N-dimethylformamide, toluene and xylene.

[0025] Also provided in this embodiment is a production process for the anti-adhesion hydrophobic coating of the pi...

Embodiment 1

[0036] An anti-adhesion hydrophobic coating formula for a pipette tip, which consists of the following components by weight fraction: 20 parts of nano silicon dioxide, 25 parts of fluorosilane, 8 parts of polyvinyl alcohol nano microspheres, 5 parts of fixative, 2 parts of defoamer, 20 parts of solvent.

[0037] Specifically, the silicon fluoride is tridecafluorooctyltriethoxysilane, the particle size of the polyvinyl alcohol nanospheres is 0.5 μm, the curing agent is polyamide, the defoaming agent is alkyl silicone oil, and the solvent is n-propanol .

Embodiment 2

[0039] An anti-adhesion hydrophobic coating formula for a pipette tip, which consists of the following components by weight fraction: 30 parts of nano silicon dioxide, 35 parts of fluorosilane, 10 parts of polyvinyl alcohol nano microspheres, 10 parts of fixative, 3 parts of defoamer, 30 parts of solvent.

[0040] Specifically, the silicon fluoride is perfluorodecyltriethoxysilane, the particle size of polyvinyl alcohol nanospheres is 0.6 μm, the curing agent is phenolic modified amine, the defoaming agent is alkyl silicone oil, and the solvent is acetone-free.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com