Copper bar packaging line system

A packaging line and wrapping material technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as slow connection and affect production efficiency, achieve efficient connection, ensure processing accuracy, and improve stacking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

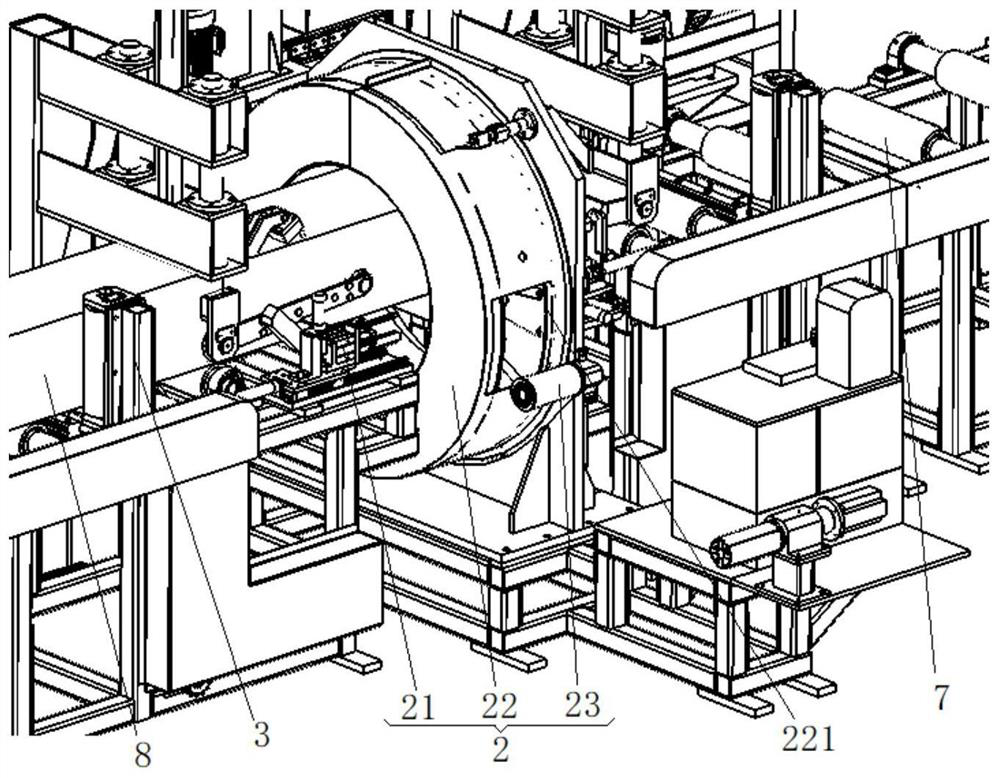

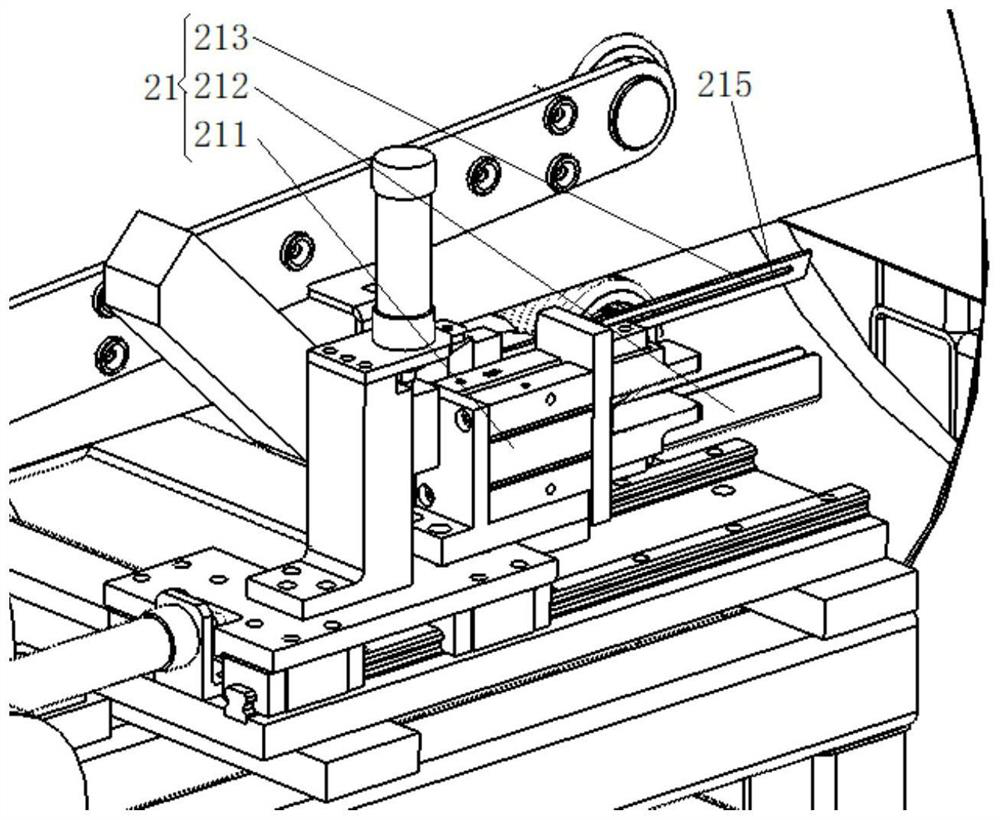

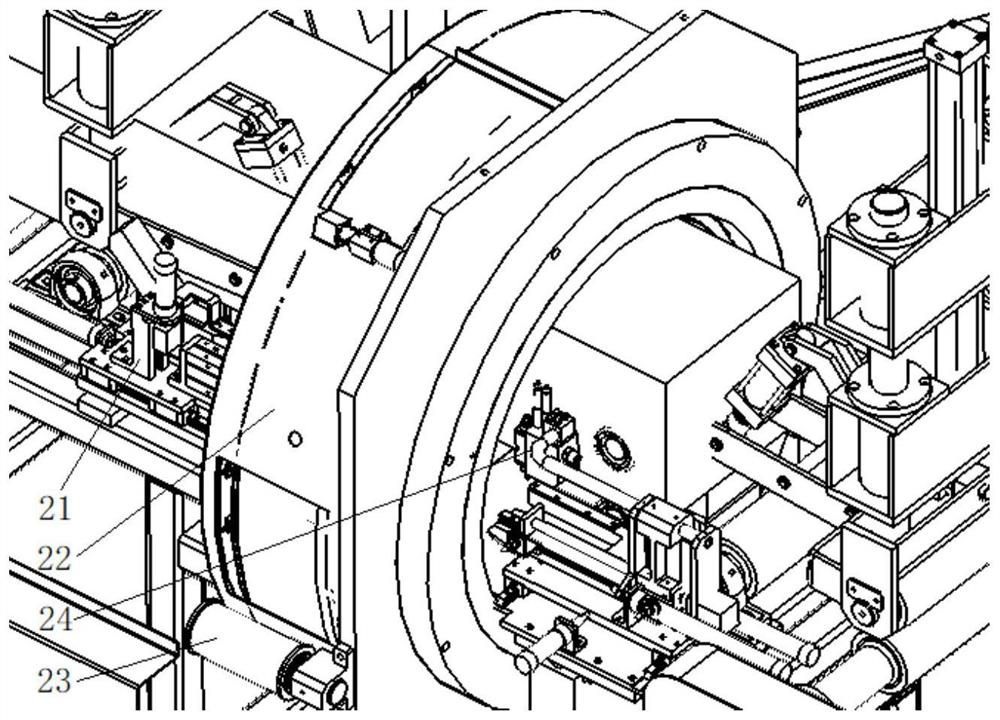

[0025] A copper bar packaging line system, including a hot melt adhesive auxiliary winding packaging device; such as figure 1 As shown, it includes a conveying roller table 7 and a surrounding assembly 2; a copper bar stack 8 is placed above the conveying roller table 7; the surrounding assembly 2 includes a positioning member 21, a ring member 22 and a material roll 23; the ring member 22 is set around the conveying roller table 7; the coil 23 is set outside the ring 22; the positioning member 21 is set inside the ring 22; the surface of the ring 22 penetrates A feed port 221 is provided; the wrapping material from the material roll 23 passes through the feed port 221 and is connected to the positioning member 21; the rotating ring 22 drives the wrapping material to wrap around the copper bar The surface of the stacking 8; because the positioning part 21 fixes the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com