Vehicle body completion bogie moving alignment device

A technology of alignment device and bogie, which is applied in the direction of workpiece clamping device and manufacturing tools, can solve the problems of low work efficiency and achieve the effects of high alignment, precise positioning and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

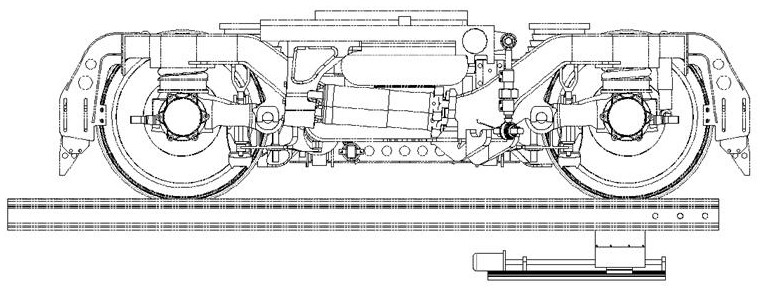

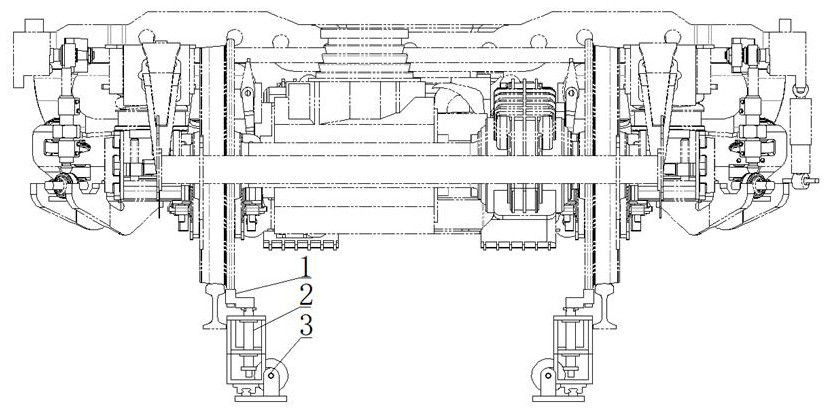

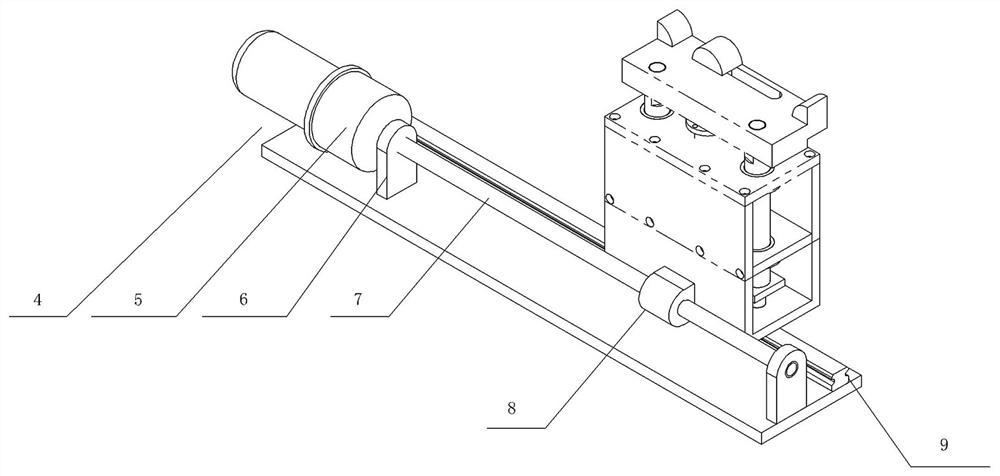

[0029] The invention relates to a mobile alignment device for a bogie when a car body is completed. The alignment device includes a wheel rim clamping device 1, a lifting device 2, a driving device 3 and a laser positioning device; the driving device 3 has a linear slide rail and is equipped with a lifting device. Device 2, the rim clamping device 1 is located on the top of the lifting device 2, and the laser positioning device is installed on the frame machine; the laser positioning device emits a cross laser line, and the laser line is positioned at the position of the center pin of the bogie as a reference point, and the driving device 3 drives the lifting The device 2 and the rim clamping device 1 move along the direction of the linear slide rail, and the rim clamping device 1 drives the bogie to move. When the center pin of the bogie coincides with the reference point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com