Chinese chestnut machine with cleaning function

A chestnut machine and functional technology, applied in cleaning methods and utensils, cleaning methods using liquids, food processing, etc., can solve problems such as inability to clean chestnuts, troublesome touching other items, sticking by hand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

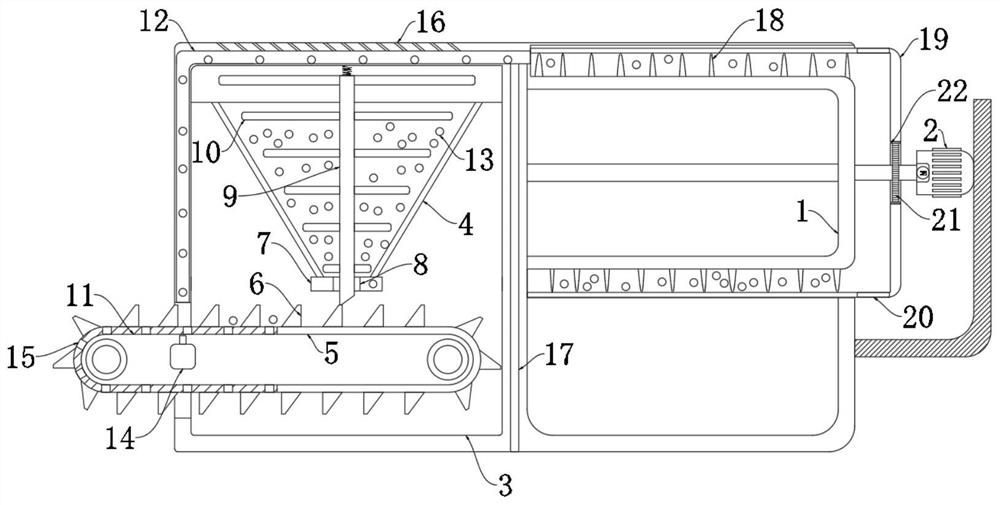

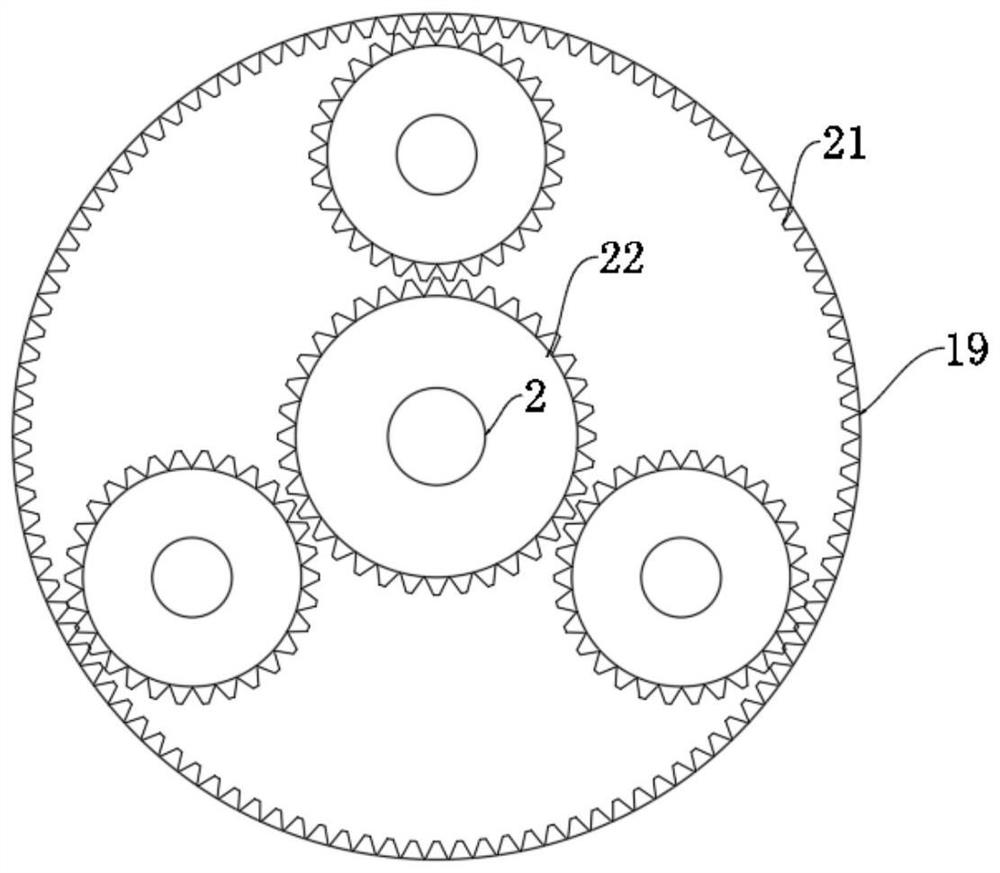

[0037] refer to Figure 1-2 , a chestnut machine with a cleaning function, comprising a chestnut machine 1, an L-shaped plate is fixedly connected to the right side wall of the chestnut machine 1, a motor 2 is arranged on the L-shaped plate, and the output shaft of the motor 2 is stirred with the chestnut machine 1 The shaft is fixedly connected; the left side of the chestnut machine 1 is fixedly connected with an installation box 3, and the installation box 3 is provided with a conical cleaning box 4, and the conical cleaning box 4 is provided with a plurality of cleaning balls 13, and a plurality of cleaning balls 13 are Cotton lightweight pellets;

[0038] The installation box 3 is provided with a belt conveyor 5, and the belt surface of the belt conveyor 5 is equidistantly fixedly connected with a plurality of wedge-shaped plates 6;

[0039] The lower end of the conical cleaning box 4 is connected with a magnetic cover plate 7 through the rotation of the transmission shaf...

Embodiment 2

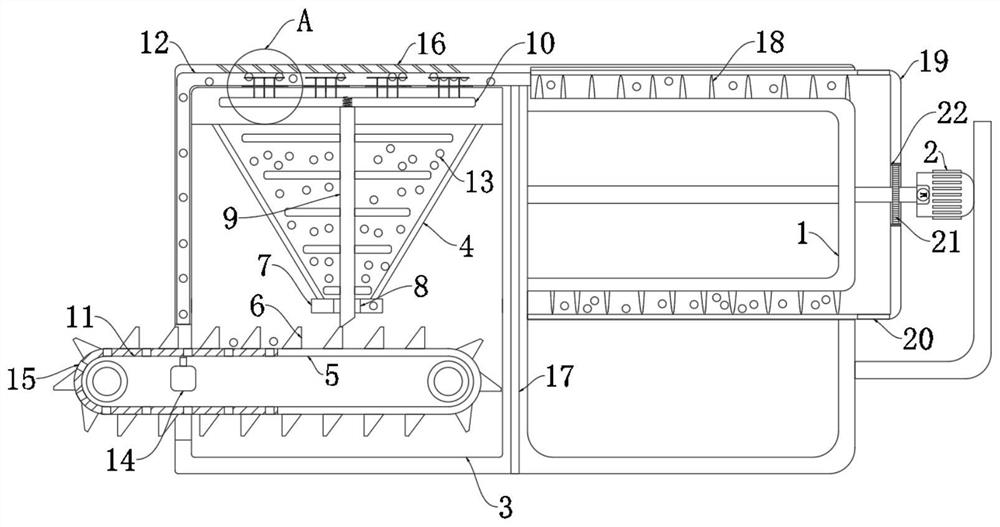

[0049] refer to Figure 3-5 The difference between this embodiment and Embodiment 1 is that the inner bottom of the guide ball channel 12 is provided with a plurality of receiving grooves 23, and a plurality of receiving grooves 23 are provided with lifting plates, and a plurality of lifting plates are provided with multiple A pressure water port 24, fixedly connected on the uppermost stirring plate 10 has many support rods connected with the lifting plate, the diameter of the water pressure port 24 is less than the diameter of the cleaning ball 13, and the thickness of the lifting plate is far less than the diameter of the cleaning ball 13. During the up-and-down reciprocating movement of the stirring plate 10 at the end, the lifting plate reciprocates up and down, so that a plurality of water pressure ports 24 push up the cleaning ball 13 to offset against the inner wall of the ball guide channel 12, and squeeze out the water in the cleaning ball 13, further increasing The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com