Mechanical pressure switch capable of realizing high-precision rigidity compensation and compensation method thereof

A pressure switch, mechanical technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of difficult to meet the high-precision adjustment of the flow system, reduce the pressure sensitivity of mechanical pressure switches, and large spring stiffness, etc., to improve the mechanics Environmental adaptability, improving sensitivity and working accuracy, reducing the effect of spring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

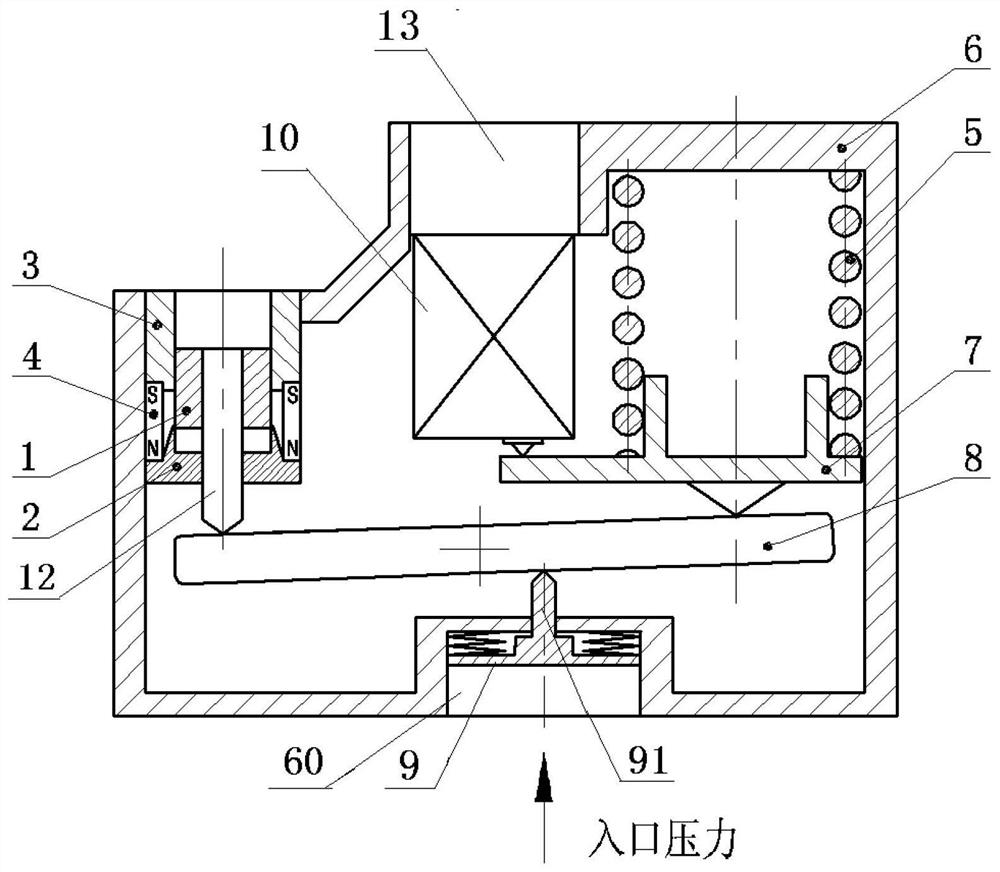

[0049] Such as figure 1As shown, a mechanical pressure switch that can realize high-precision stiffness compensation in this embodiment includes a microswitch 10, a housing 6, a pressure sensing unit arranged on the housing 6, and a Lever 8, compensation unit and reset unit;

[0050] The micro switch 10 is fixed in the housing 6 , and an outlet hole 13 is arranged above the micro switch 10 , and the micro switch 10 is electrically connected to the pump outside the housing 6 through the outlet hole 13 .

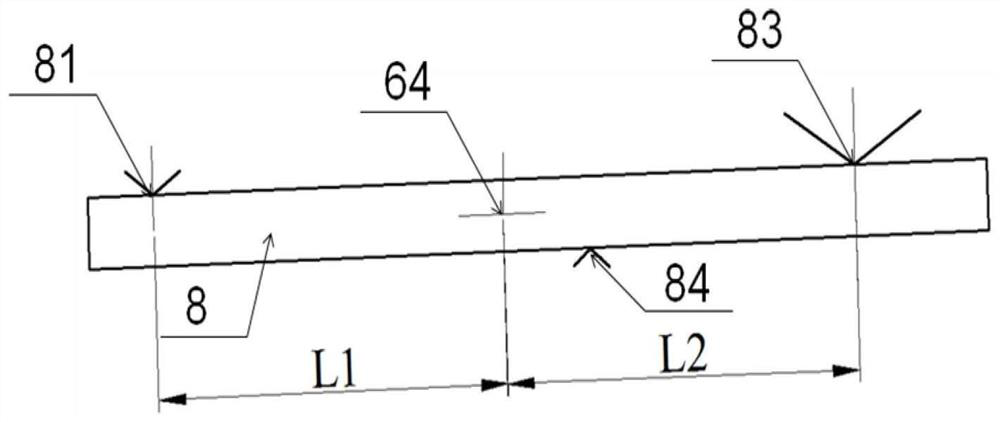

[0051] Such as image 3 As shown, there is a permanent magnet contact point 81, a return spring contact point 83 and a pressure-sensitive piston contact point 84 on the lever 8;

[0052] The pressure-sensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com