Tank prying type LNG generator set based on separated water tank heat dissipation system

A technology for generating sets and heat dissipation systems, which is applied in the direction of charging systems, engine components, combustion engines, etc., and can solve the problem of the small internal space of container-type LNG generating sets, which affects the safety of gasifiers and LNG storage tanks, and the effect of ventilation and heat dissipation Poor and other problems, to avoid displacement, ensure integrity, reduce the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

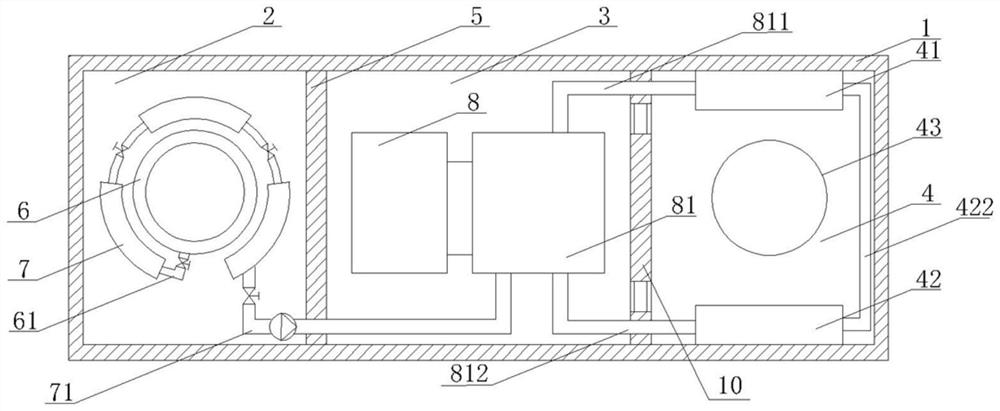

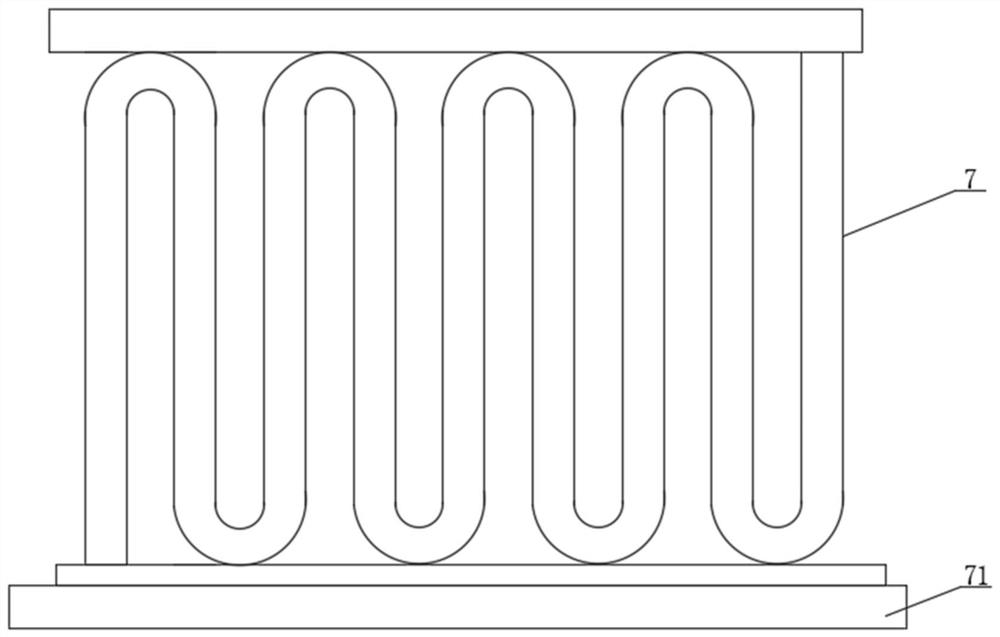

[0042] Such as Figure 1-9As shown, a box-based LNG generator set based on a separating water tank heat dissipation system includes a generator set, including a gasifier, a power zone 3, and a heat dissipation zone 4, a gasification zone 2 top. With Ges, a first double opening door is provided on the side of the gasification area, and the first double opening door is opened, and the first heat sink 12 is used to ensure the air of the gasifier 2 side. Circulation, reduce heat retention;

[0043] The gasification region 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com