A kind of processing method of ceramic-based stone composite board

A processing method and composite board technology, which is applied in the field of composite boards, can solve problems such as difficult clamping methods, corrosion, and unsightly composite boards, and achieve an overall smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

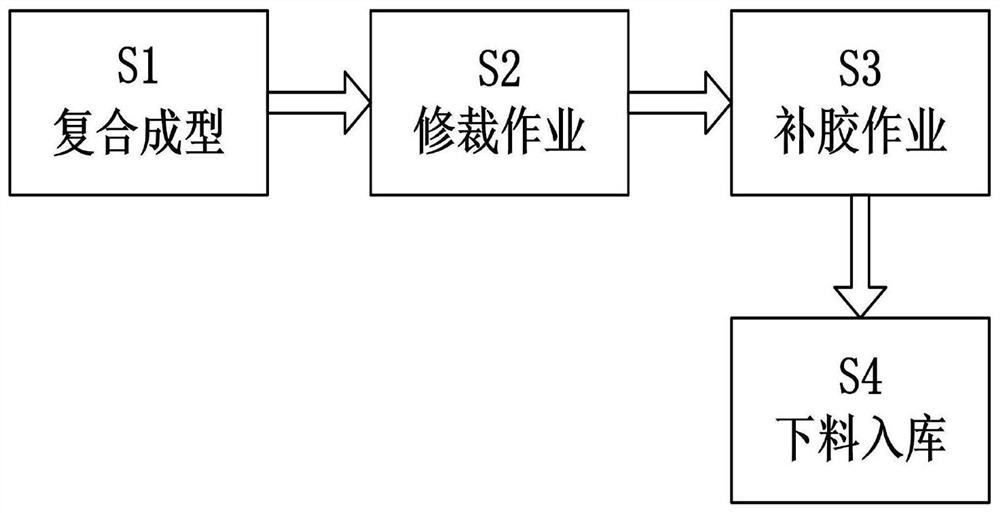

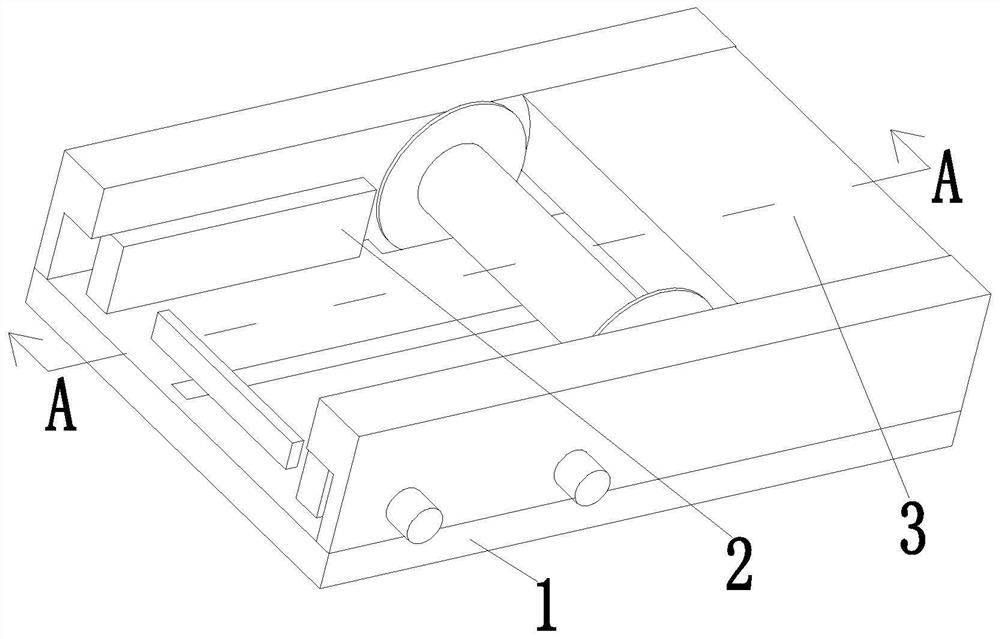

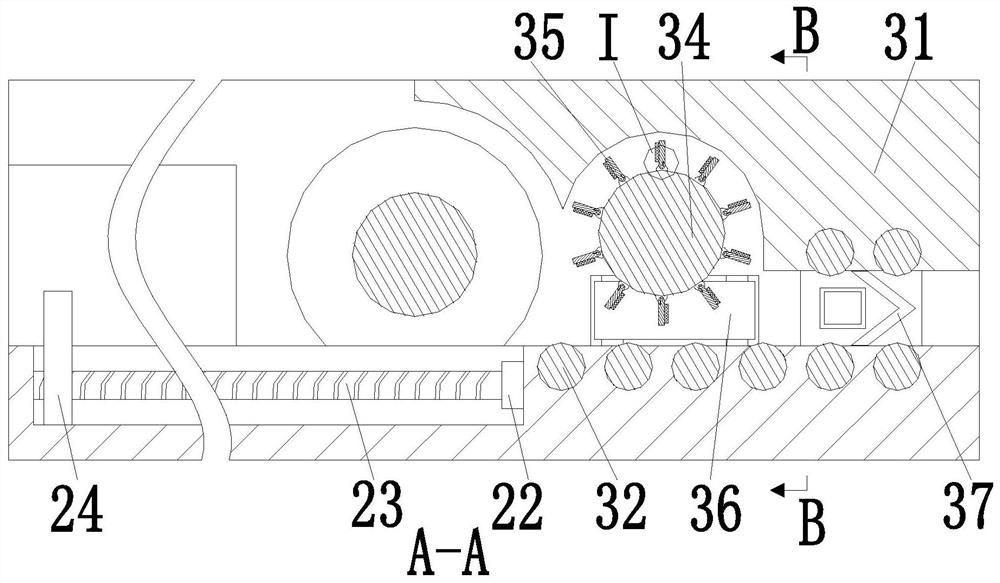

[0032] like Figure 1 to Figure 7 As shown in the figure, a method for processing a ceramic-based stone composite panel, which uses a cutting and repairing glue equipment, the cutting and repairing glue equipment includes a base 1, a feeding and trimming device 2 and an auxiliary glue repairing device 3. The processing method of the composite board by the glue equipment also includes the following steps:

[0033] S1. Composite molding: composite the ceramic and the base stone through the adhesive, so that the composite board is formed;

[0034] S2. Trimming operation: trim both sides of the composite board through the feeding and cutting device 2, so that the width of the composite board is consistent;

[0035] S3. Glue replenishing operation: carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com