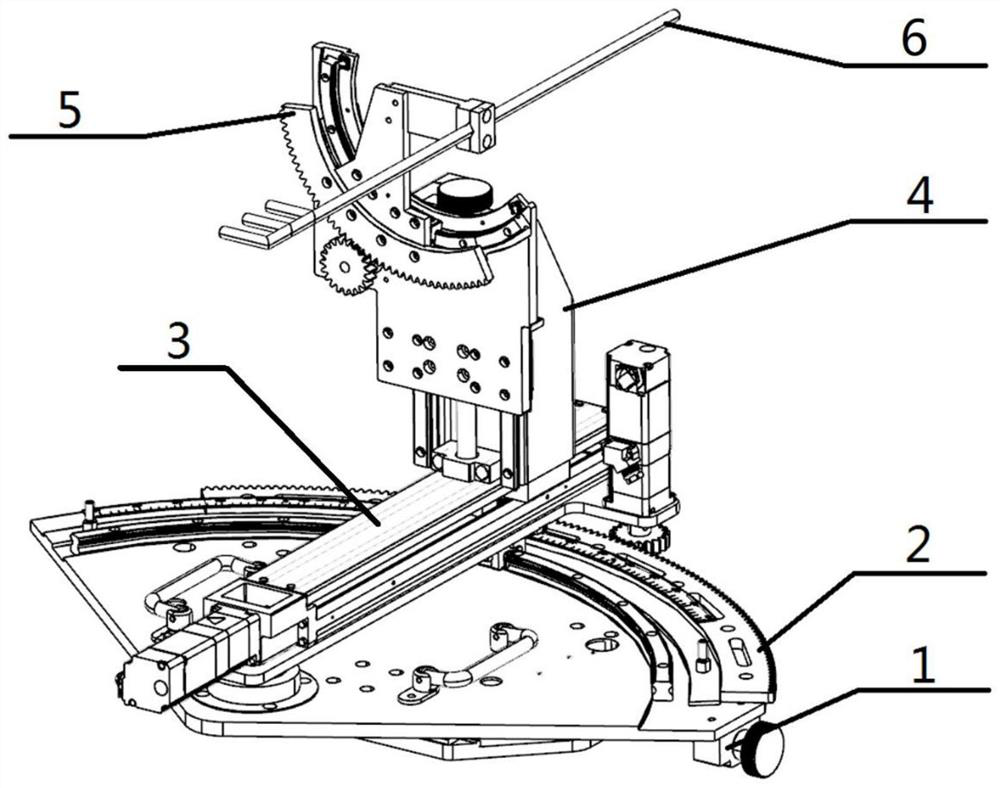

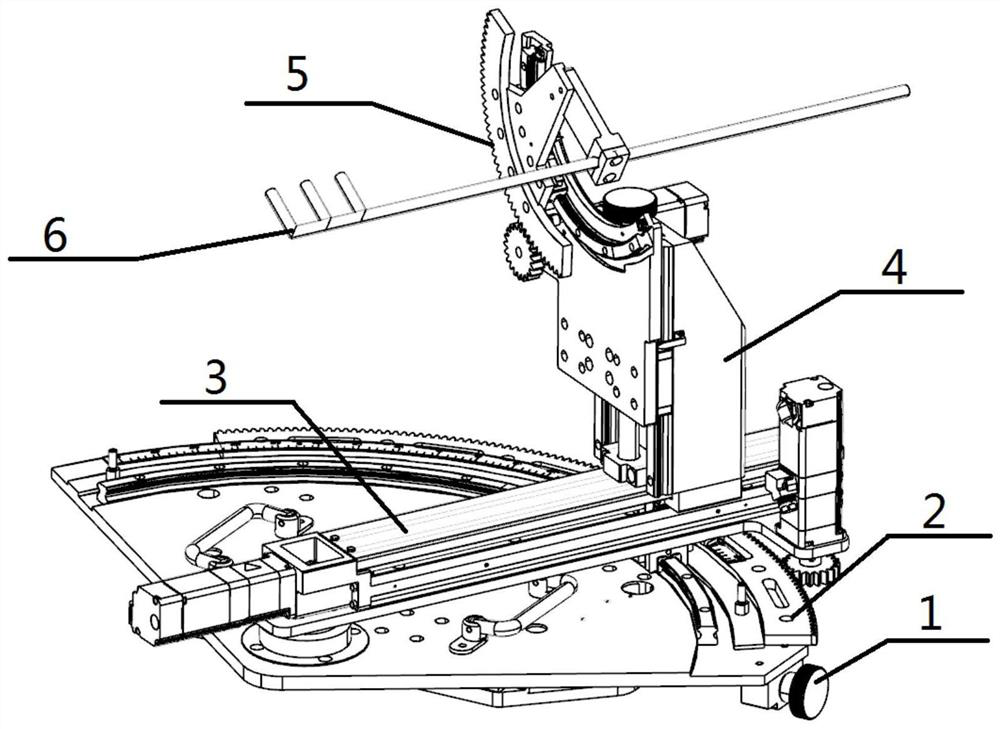

Five-degree-of-freedom probe clamping device for pneumatic probe calibration

A clamping device and a degree of freedom technology, applied in the field of wind tunnel testing, which can solve the problems of deviation from the center of the nozzle outlet, low calibration efficiency, and no automatic adjustment function of the calibration position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

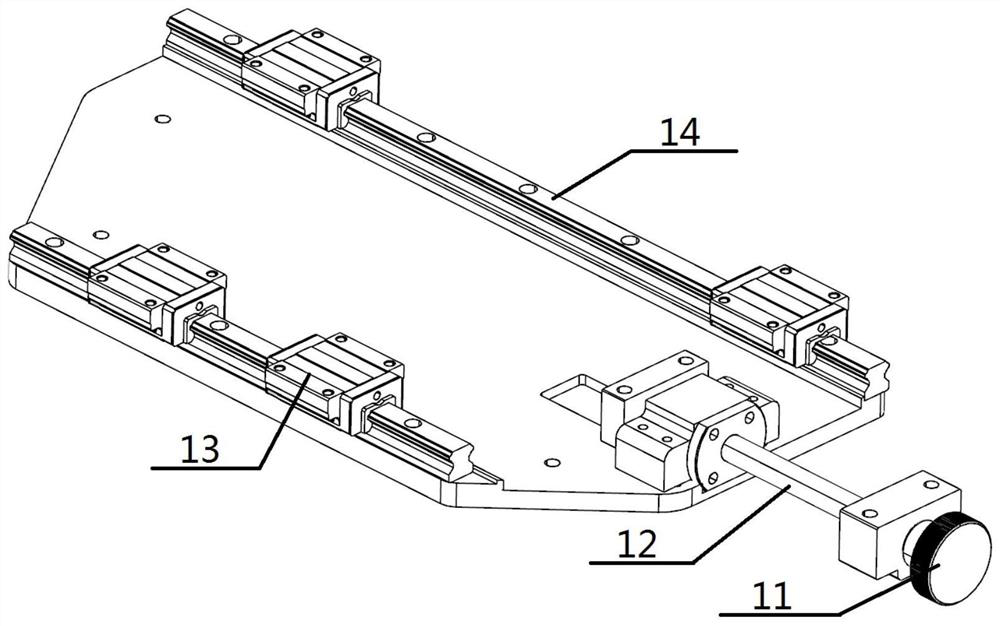

Method used

Image

Examples

Embodiment 1

[0038] The method of using the five-degree-of-freedom probe clamping device for pneumatic probe calibration in this embodiment is as follows:

[0039] Before calibrating the probe 6, first replace the clamping part 51 adapted to the probe 6, and clamp the probe 6 stably on the clamping part 51; secondly, adjust the pitch mechanism 5 and the yaw mechanism 2 to the zero position, Then adjust the X-direction displacement mechanism 1, Y-direction displacement mechanism 4 and Z-direction displacement mechanism 3 in turn to ensure that the first sensing part of the probe 6 is located in the core flow field of the nozzle outlet; then set the pitch of each calibration state Angle, yaw angle, and Z-coordinates of other sensing parts; finally, the calibration wind tunnel is opened, and each sensing part is calibrated with variable pitch angle and yaw angle in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com