Small and light-weight high-power heavy-load electric wheel lubricating and sealing method and structure

A technology with a sealing structure and high power density, which is applied in the direction of gear lubrication/cooling, electric components, electromechanical devices, etc., and can solve the problems of lack of sealing and lubrication for the miniaturization and light weight of electric drive wheels, so as to ensure lubrication and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

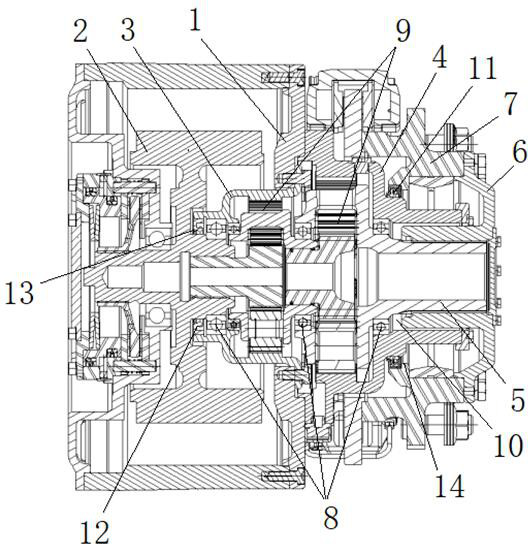

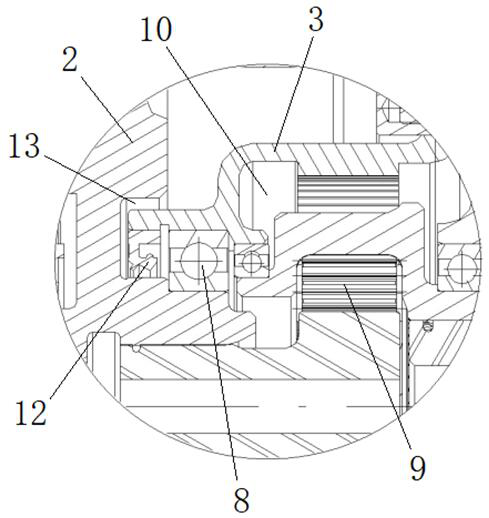

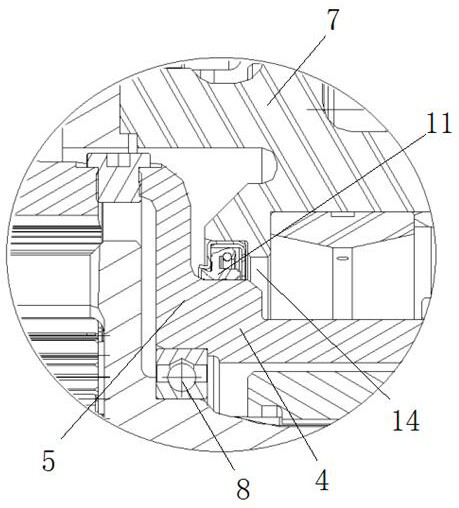

[0031] From attached figure 1 It can be seen that the present invention relates to a small, lightweight, high-power, heavy-duty electric wheel lubrication and sealing structure, including a drive motor end cover 1, a drive motor rotor 2, a reducer left end casing 3, a reducer right end casing 4, and a reducer Output shaft 5, wheel hub connection support ring 6 and wheel hub 7; drive motor end cover 1, drive motor rotor 2, reducer left end casing 3, reducer right end casing 4, reducer output shaft 5, wheel hub connection support ring 6 The airtight space 10 formed by combining with the hub 7 is provided with a bearing 8 and a gear 9 in the airtight space 10; seals 11, 12 are arranged at the positions of the static and dynamic joints in the airtight space 10, and the seals 11, 12 Seal the dynamic and static joints in the enclosed space 10 .

[0032] Further, through the analysis of the integrated structure of the drive motor and the reducer, it is determined that the positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com