Multi-dimensional rapid building method for high-strength bamboo corridor

A high-strength, corridor technology, applied in the processing of building materials, climate change adaptation, building materials, etc., can solve the problems of low structural strength, long construction period and slow construction speed for multi-dimensional construction of bamboo corridors. Set up quick, easy, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

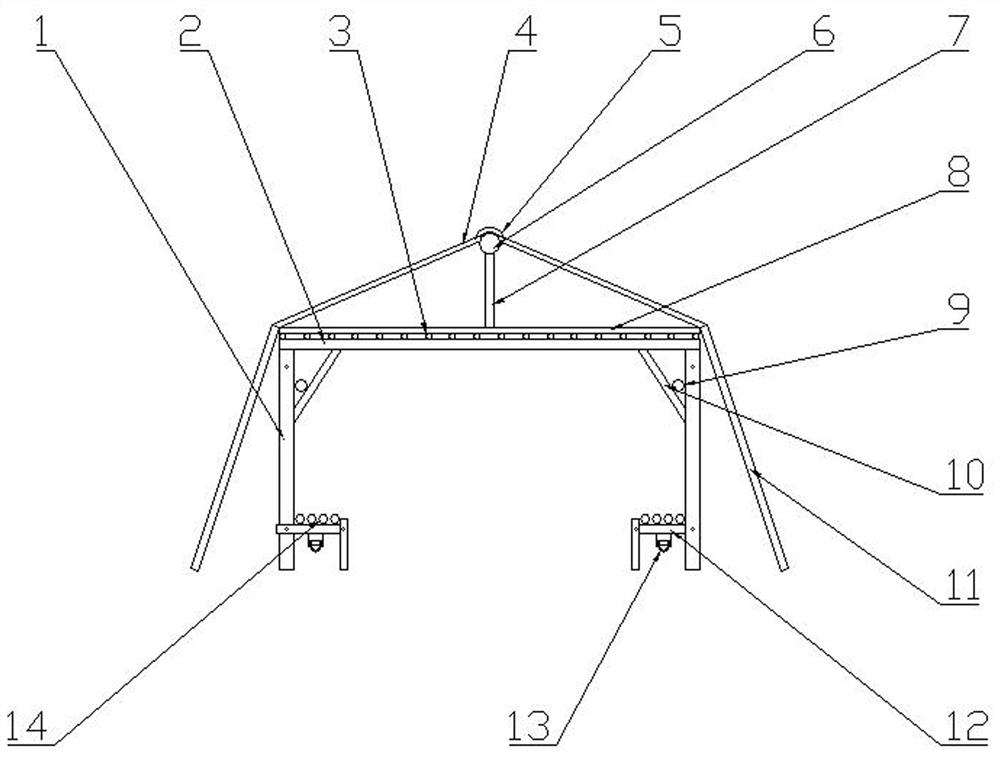

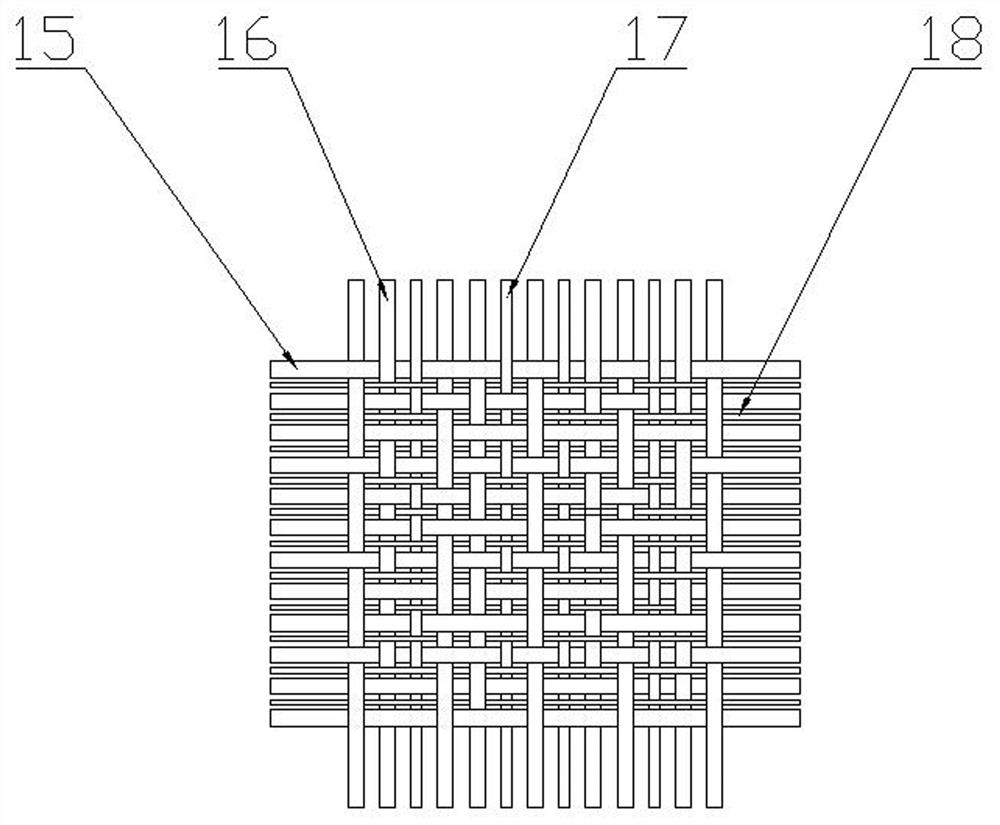

[0034] Example: such as Figure 1-10 As shown, a high-strength bamboo corridor multi-dimensional rapid erection method includes the following steps:

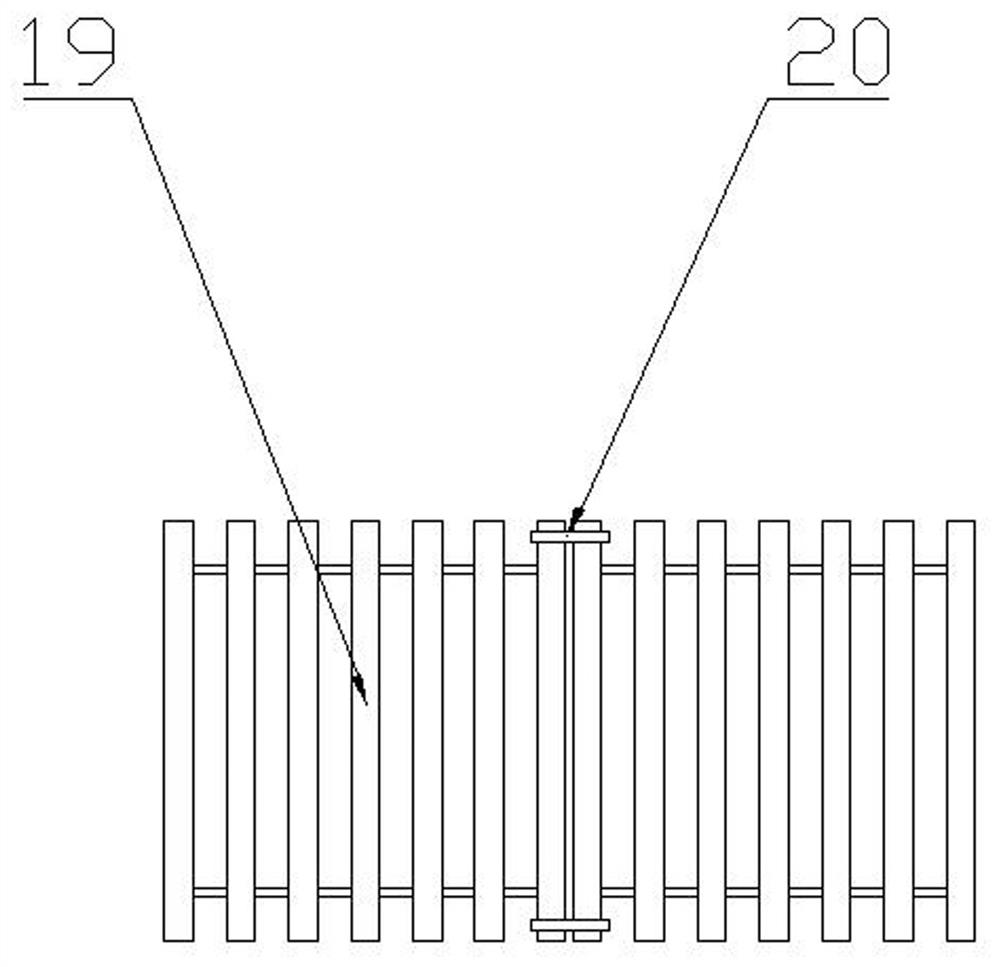

[0035] The first step: process the wall assembly 1, and connect and fix the upper and lower ends of 8 groups of adjacent wall bamboo rows 19 with hoops 20.

[0036] 9 bamboo poles are placed in the processing platen 32 of the wall bamboo raft, and the pressure rods 35 are inserted into the two pairs of side ear plates 34 on the upper ends of the two sides of the processing platen 37, then the upper ends of the bamboo poles are cut to form the bamboo poles 21, and then the lifting frame 38 is adjusted. Make the screw shaft 40 concentric with the plunger hole 36, then insert the hole saw assembly 42 into the screw shaft 40, lock it with the locking gear nut 41, and then start the drive motor 39 to drive the hole saw assembly 42 to process The vertical bamboo pole 21 in the platen 37 is drilled. The hole saw assembly 42 uses a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com