Preparation process of antibacterial film

A preparation process and film technology, applied in the field of the preparation process of antibacterial films, can solve the problems of contaminated food or medicine, insignificant antibacterial effect, mildew, etc., to enhance surface adhesion, improve low film strength, and high film strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

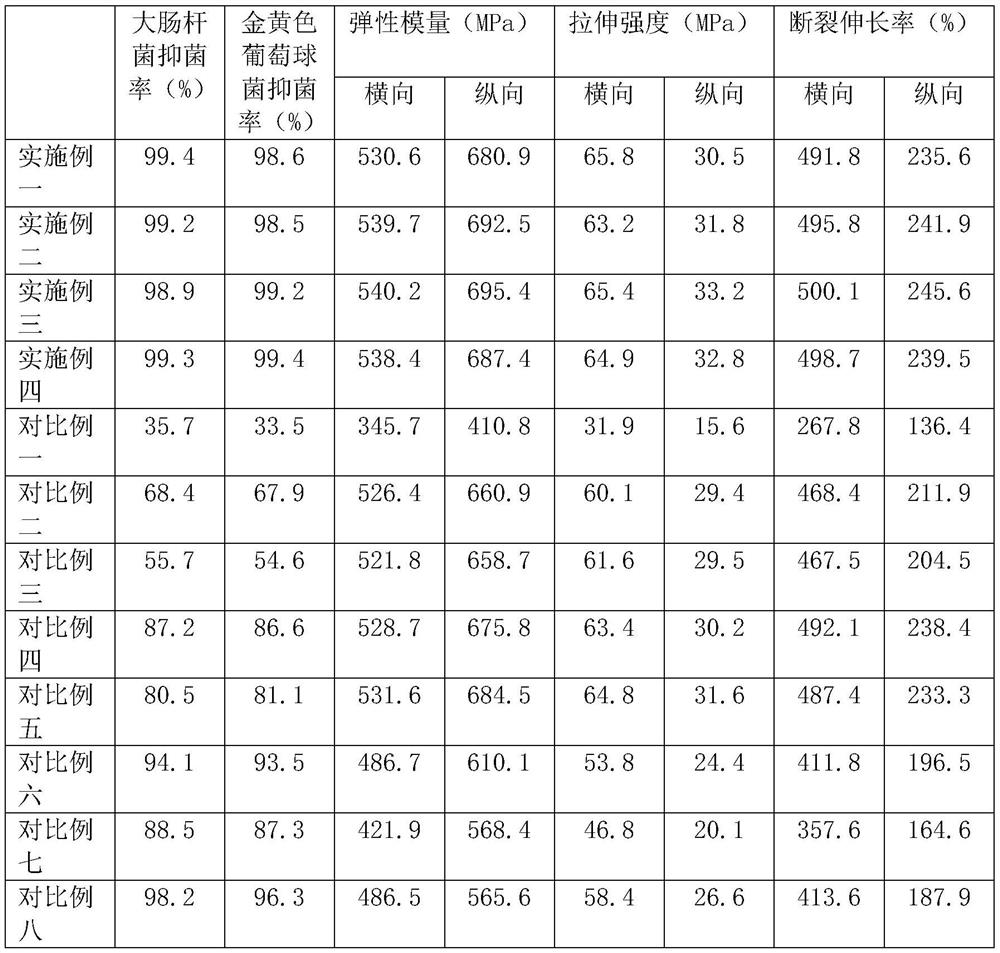

Examples

Embodiment 1

[0035] A preparation process of antibacterial film, in parts by weight, take 1 part of nano-silver antibacterial agent, 100 parts of polyethylene resin blends, 2 parts of modified lignocellulose, 0.5 parts of silver-loaded nano-zinc oxide, plasticized 1 part of agent, 0.05 part of dispersant and 0.1 part of antioxidant are mixed, and after mixing, granulation, drying and film blowing are carried out to prepare antibacterial film.

[0036] Described nano-silver antibacterial agent is prepared according to the following steps:

[0037] Step a: Take dandelion leaves and dandelion roots, dry and pulverize them respectively, mix dandelion leaves and dandelion roots at a weight ratio of 1:2, mix dandelion leaves and dandelion roots, mix with 50% ethanol solution, and heat at 100°C Reflux for 30 min, repeat 3 times, combine the extracts for 3 times, evaporate under reduced pressure at 35°C to obtain dandelion extract extract, then dilute the dandelion extract extract to 100 mg / mL wit...

Embodiment 2

[0057] A preparation process of antibacterial film, in parts by weight, take 2 parts of nano-silver antibacterial agent, 120 parts of polyethylene resin blends, 4 parts of modified lignocellulose, 1 part of silver-loaded nano-zinc oxide, plasticizer 2 parts of agent, 0.1 part of dispersant and 0.6 part of antioxidant are mixed, and after mixing, granulation, drying and film blowing are carried out to prepare antibacterial film.

[0058] Described nano-silver antibacterial agent is prepared according to the following steps:

[0059] Step a: take dandelion leaves and dandelion roots, dry and pulverize them respectively, mix dandelion leaves and dandelion roots at a weight ratio of 1:3, mix dandelion leaves and dandelion roots, mix with 50% ethanol solution, and heat at 100°C Reflux for 40 min, repeat 3 times, combine the extracts for 3 times, evaporate under reduced pressure at 35°C to obtain dandelion extract extract, then dilute the dandelion extract extract to 100mg / mL with 7...

Embodiment 3

[0079] A preparation process of antibacterial film, in parts by weight, take 1.5 parts of nano-silver antibacterial agent, 110 parts of polyethylene resin blends, 3 parts of modified lignocellulose, 0.75 parts of silver-loaded nano-zinc oxide, plasticized 1.5 parts of agent, 0.075 part of dispersant and 0.35 part of antioxidant are mixed, and after mixing, granulation, drying and film blowing are carried out to prepare antibacterial film.

[0080] Described nano-silver antibacterial agent is prepared according to the following steps:

[0081] Step a: take dandelion leaves and dandelion roots, dry and pulverize them respectively, mix dandelion leaves and dandelion roots at a weight ratio of 1:2.5, mix dandelion leaves and dandelion roots, mix with 50% ethanol solution, and heat at 100°C Reflux for 35 minutes, repeat 3 times, combine the extracts for 3 times, evaporate under reduced pressure at 35°C to obtain dandelion extract extract, then dilute the dandelion extract extract t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com