Ultrasonic responsive 4D printed porous ceramic part and preparation method thereof

A porous ceramic and ultrasonic technology, applied in ceramic products, ceramic molding machines, applications, etc., can solve the problem that ceramic parts do not have deformation function, etc., and achieve the effects of rich variety, effective control, and strong remote control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

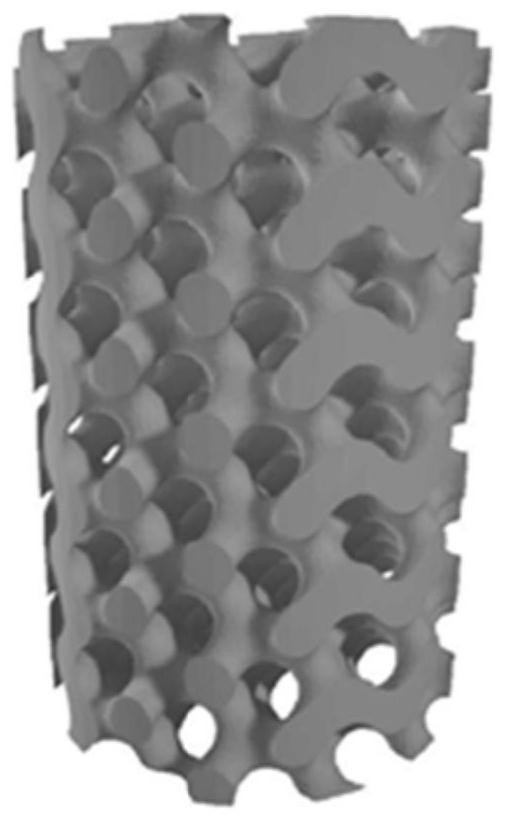

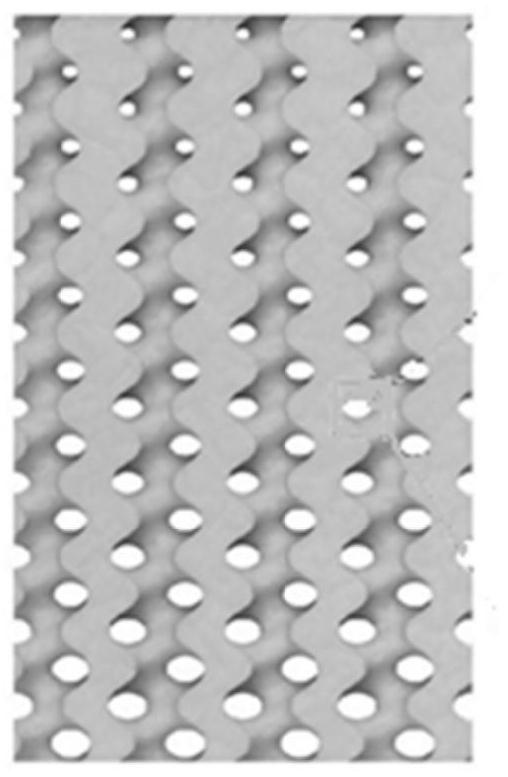

[0026] see figure 1 , figure 2 and Figure 5 , the preparation method of the ultrasonic-responsive 4D printing porous ceramic piece provided by the present invention mainly includes the following steps:

[0027] Step 1, preparation of ceramic powder material.

[0028] Specifically, single-phase or multi-phase uniformly mixed piezoelectric ceramic powder is selected as the raw material, wherein the piezoelectric ceramic powder is the main phase material. The piezoelectric ceramic powder is preferably one or more of zinc oxide, boron nitride, barium titanate, barium zirconate titanate, barium calcium zirconate titanate, potassium sodium metaniobate, potassium barium metaniobate, The addition amount is not less than 20 wt%, and the particle size of the powder is preferably 0.5-20 μm.

[0029] Step 2, porous structure design.

[0030] Specifically, three-dimensional modeling software is used to design a porous model with different pore structure characteristics, and the poro...

Embodiment 1

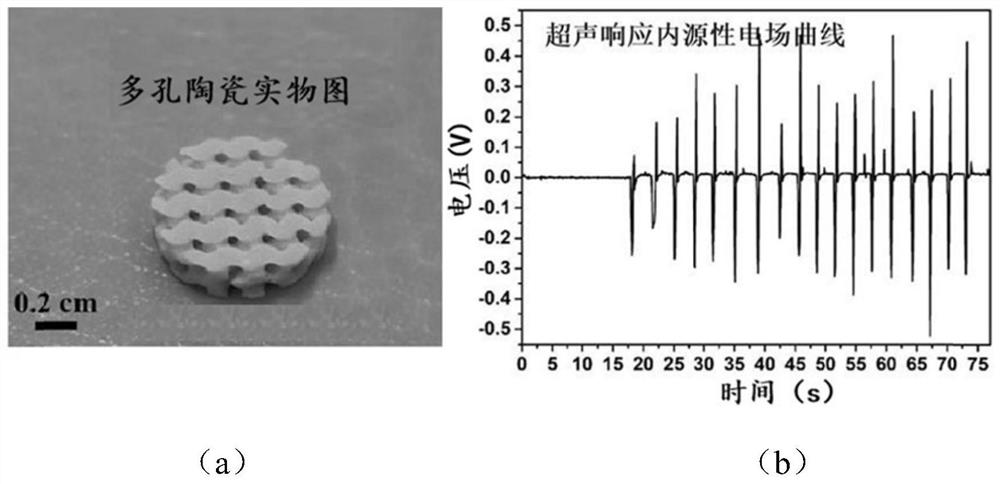

[0040] see image 3 , a preparation method of ultrasonic responsive 4D printing porous ceramic material, the specific steps are as follows:

[0041] (1) Select barium zirconate titanate powder with an average particle size of 0.5 μm as the raw material;

[0042] (2) Using 3D modeling software to design a 3D model of a uniform porous structure, the porosity is 60%, the pore size is 450 μm, and the pore connectivity rate is 57.5%;

[0043] (3) uniformly mixing 47.5vol% ceramic powder with 52.5vol% photocurable resin monomer, 1.25wt% photoinitiator, 2.75wt% dispersant, etc. to obtain slurry;

[0044] (4) 4D printing of ceramic parts: import the porous model, light-cured the printing paste to obtain a green body, and sintered the green body at a DC voltage of 3500V / m and polarized at 65 °C for 17.5 minutes, and finally obtained an ultrasonic-responsive 4D printed ceramic part.

Embodiment 2

[0046] see Figure 4 , a preparation method of ultrasonic responsive 4D printing porous ceramic material, the specific steps are as follows:

[0047](1) Select barium calcium zirconate titanate / hydroxyapatite powder with an average particle size of 10 μm as the raw material, wherein the content of barium calcium zirconate titanate powder is 60wt%;

[0048] (2) A three-dimensional model of a uniform porous structure was designed by using three-dimensional modeling software, with a porosity of 90%, a pore size of 200 μm, and a pore connectivity rate of 20%;

[0049] (3) uniformly mixing 60vol% ceramic powder with 40vol% photocurable resin monomer, 2.0wt% photoinitiator, 5.0wt% dispersant, etc. to obtain slurry;

[0050] (4) 4D printing of ceramic parts: import the porous model, light-cured the printing paste to obtain a green body, and sintered the green body at a DC voltage of 2000 V / m and polarized at 20 °C for 5 minutes, and finally obtained an ultrasonic response 4D printed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com