Expansion agent for concrete as well as preparation and use methods of expansion agent

An expansion agent, concrete technology, applied in the field of concrete expansion agent, can solve unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

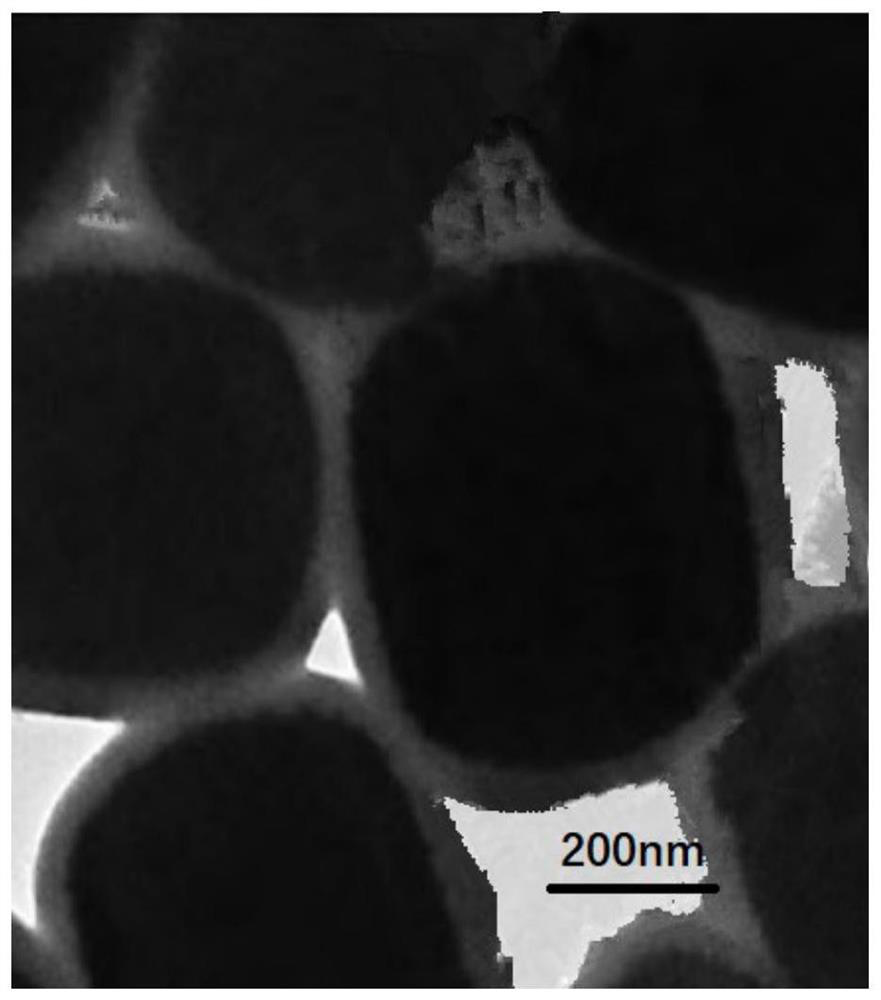

Image

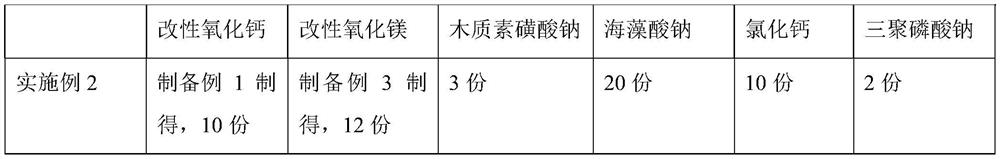

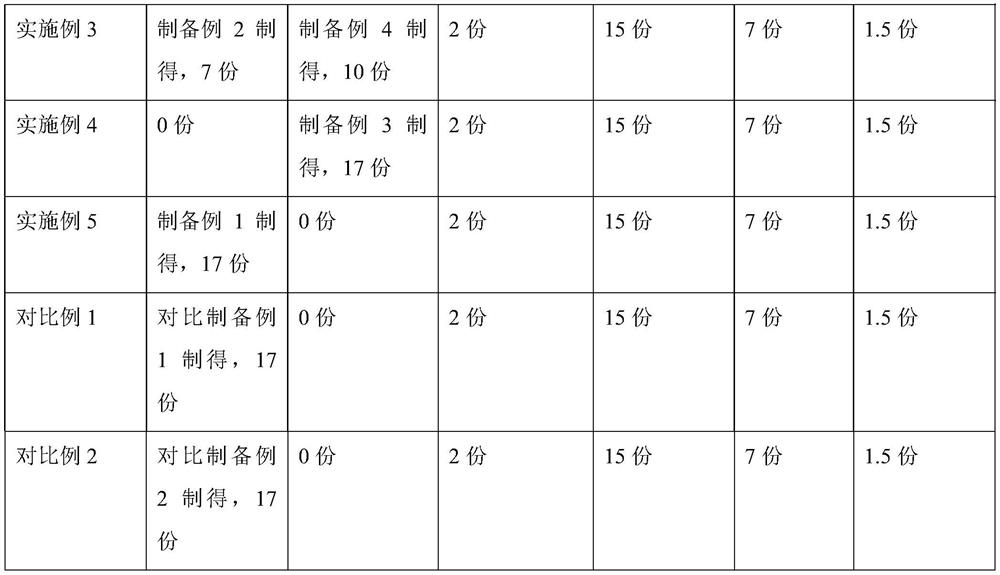

Examples

preparation example 1

[0033] The preparation of preparation example 1 modified calcium oxide

[0034] Composition of raw materials (parts by weight): 50 parts of calcium oxide, 4 parts of citric acid, 10 parts of bentonite, and 50 parts of ethanol.

[0035] Methods as below:

[0036]S1. Dry calcium oxide at 100°C, then add citric acid, bentonite and ethanol in proportion, and ball mill and mix for 4 hours;

[0037] S2. Filter the mixture in step S1, wash, and dry at 100° C. for 20 minutes;

[0038] S3. Calcining the dried product obtained in step S2 at 500° C. for 1 hour, and then pulverizing it to 200 mesh to obtain modified calcium oxide.

preparation example 2

[0039] Preparation of Preparation Example 2 Modified Calcium Oxide

[0040] Composition of raw materials (parts by weight): 40 parts of calcium oxide, 3 parts of citric acid, 7 parts of bentonite, and 40 parts of ethanol.

[0041] Methods as below:

[0042] S1. Dry calcium oxide at 90°C, then add citric acid, bentonite and ethanol in proportion, and ball mill and mix for 3 hours;

[0043] S2. Filter the mixture in step S1, wash, and dry at 90° C. for 15 minutes;

[0044] S3. After calcining the dried product obtained in step S2 at 450° C. for 1 hour, it was crushed to 150 mesh to obtain modified calcium oxide.

preparation example 3

[0059] Preparation of Preparation Example 3 Modified Magnesium Oxide

[0060] Composition of raw materials (parts by weight): 30 parts of magnesium oxide, 2 parts of citric acid, 5 parts of bentonite, and 30 parts of ethanol.

[0061] Methods as below:

[0062] S1. Dry the magnesium oxide at 80°C, then add citric acid, bentonite and ethanol in proportion, and ball mill and mix for 2 hours;

[0063] S2. Filter the mixture in step S1, wash, and dry at 80° C. for 10 minutes;

[0064] S3. After calcining the dried product obtained in step S2 at 400° C. for 0.5 h, it was crushed to 100 mesh to obtain modified magnesium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com