Compound high-performance expanding agent for cement-based material

A cement-based material and expansion agent technology, applied in the field of cement-based material admixtures, can solve the problems of insufficient cement slurry, high alkali content of the expansion agent, non-conformance, etc., to prevent cracks, excellent expansion performance, and save engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

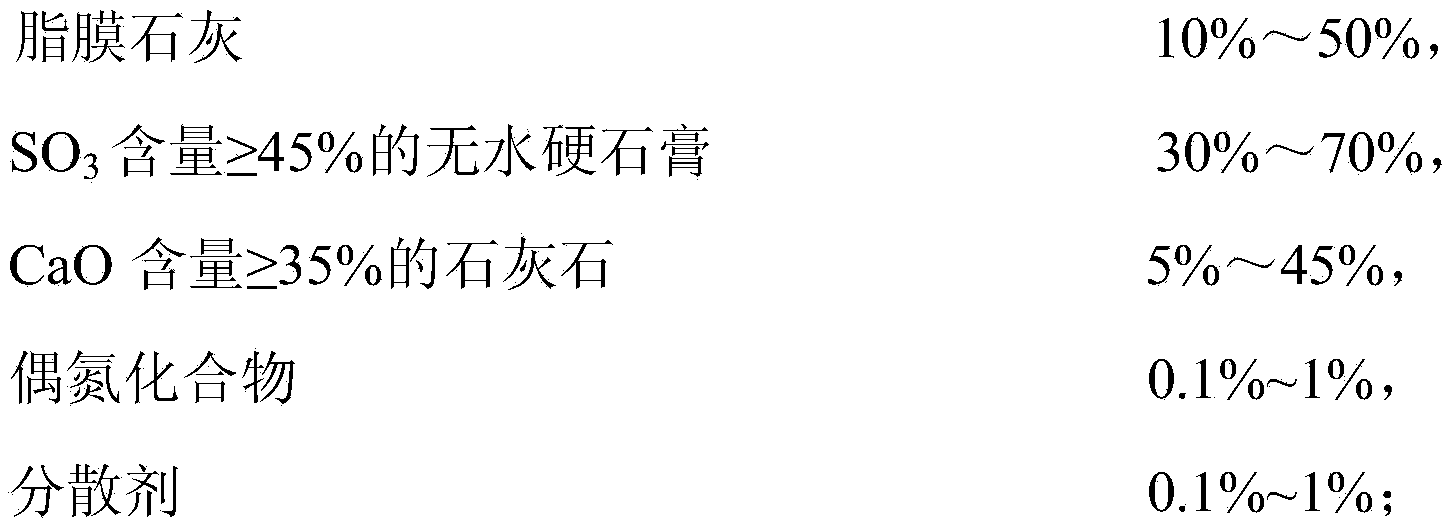

[0030] Taking 100KG composite high-performance expansion agent as an example, its formula is:

[0031] Weigh 35KG of lipid film lime powder, 45KG of anhydrite powder, and 19.3KG of limestone powder, mix and grind until the specific surface area reaches 300m 2 / kg~600m 2 / kg, then add 0.4KG of azodicarbonamide and 0.3KG of sodium tripolyphosphate, and mix for 15 minutes. Made into cement concrete composite high-performance expansion agent. The experimental materials used Huaxin 42.5 grade ordinary Portland cement and polycarboxylate high-efficiency water reducer. The experimental ratio was: cement 2760g, expansion agent 240g, water reducer 6g, water-cement ratio 0.27, tested according to national standards, and tested performance indicators as follows:

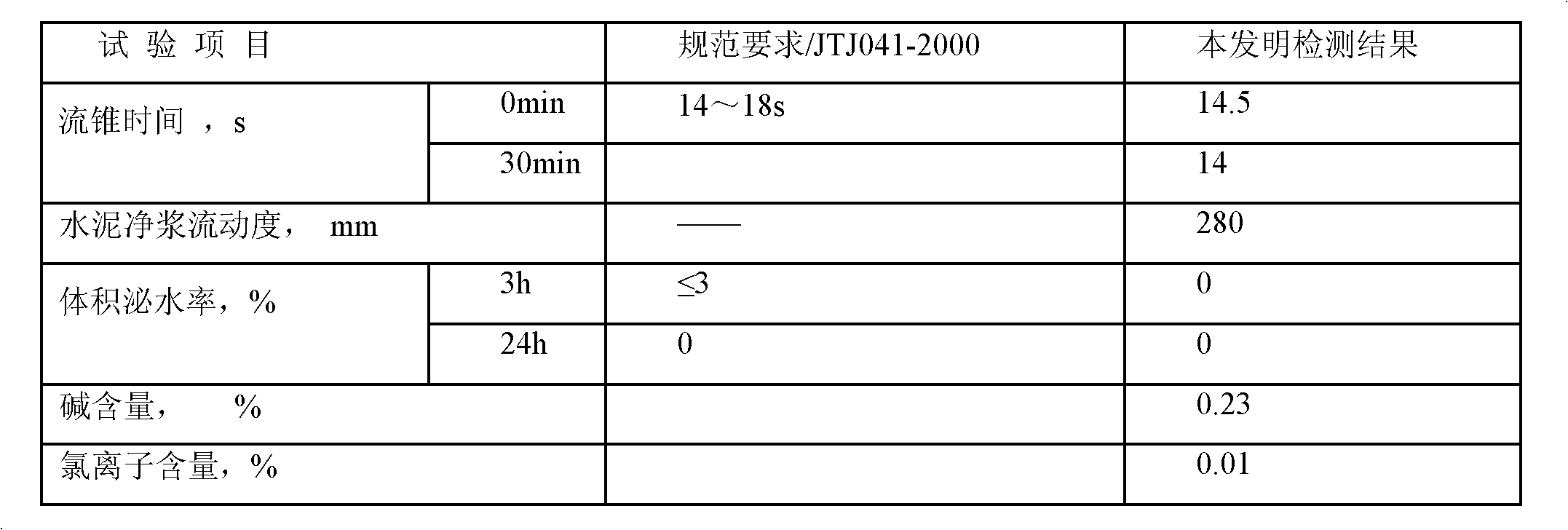

[0032] Table 1 The detection data of the present invention compares with the technical performance of the construction specification

[0033]

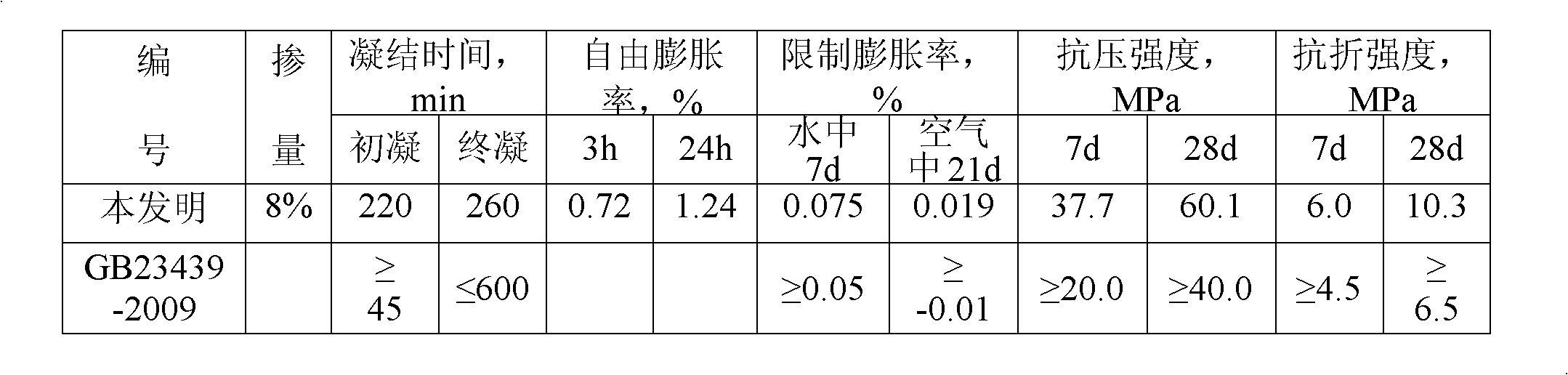

[0034] Table 2 The detection data of the present invention is compared with ...

Embodiment 2

[0038] Taking 100KG composite high-performance expansion agent as an example, its formula is:

[0039] Weigh 30KG of lipid film lime, 50KG of anhydrite, and 19.4KG of limestone powder, mix and grind until the specific surface area reaches 300m 2 / kg~600m 2 / kg; add 0.4KG of a mixture of azodicarbonamide and azobisisobutyronitrile in a weight ratio of 1:1, and 0.2KG of sodium hexametaphosphate. Mix for 15 min. Made into cement concrete composite high-performance expansion agent. According to the national standard test, when the dosage accounts for 9% of the total mass of cement-based materials, the limit expansion rate of 7 days in water curing is 0.061%, the limit expansion rate of 21 days in air curing is 0.022%, and the compressive strength of 7 days is 36.2MPa. The 28-day compressive strength is 59.7MPa, the 7-day flexural strength is 6.3MPa, and the 28-day flexural strength is 10.1MPa, which meets the requirements of the "Concrete Expansive Agent" GB23439-2009 standard;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com