Moisture-permeable soft composite core and preparation method thereof

A composite core and soft technology, applied in sanitary napkins, absorbent pads, underwear, etc., can solve the problems of low utilization rate of superabsorbent resin, and achieve the effects of good compressibility, reduced usage, and fast absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

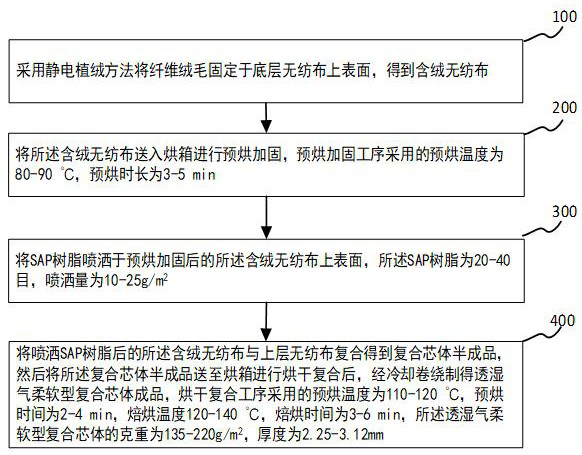

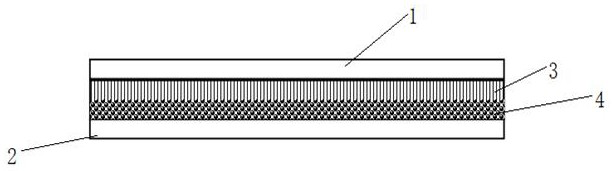

[0032] figure 1 It is a method flowchart of a method for preparing a moisture-permeable flexible composite core shown according to an exemplary embodiment, as shown in figure 1 Shown, described preparation method comprises:

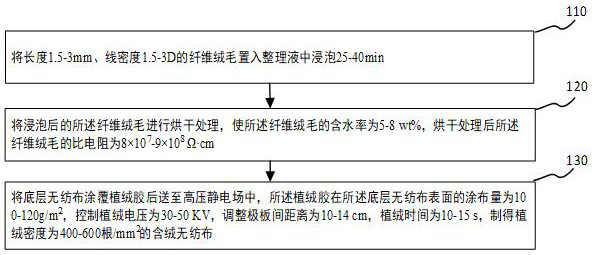

[0033] Step 100: Using electrostatic flocking method to fix the fiber fluff on the upper surface of the bottom non-woven fabric to obtain the fluff-containing non-woven fabric.

[0034] Step 200: Send the cashmere-containing non-woven fabric into an oven for pre-drying and strengthening. The pre-drying temperature used in the pre-drying and strengthening process is 80-90° C., and the pre-drying time is 3-5 minutes.

[0035]Step 300: Spray a superabsorbent resin on the upper surface of the fleece-containing nonwoven fabric after pre-baking and strengthening, the superabsorbent resin is 20-40 mesh, and the spraying amount is 10-25g / m 2 .

[0036] Step 400: Combine the cashmere-containing non-woven fabric sprayed with superabsorbent resin and the upper no...

Embodiment 1

[0050] (1) Soak fiber fluff with a length of 1.mm and a linear density of 1.5D in the finishing solution for 25 minutes. The temperature of the finishing solution is 45°C and the bath ratio is 1:30. The components in the finishing solution Percent by weight: 0.5wt% penetrant JFC, 2wt% K 2 SO 4 , 2wt% nonionic antistatic agent, 3wt% silica sol, 2wt% MgCl 2 , 1 wt% softener, 0.5 wt% glacial acetic acid, and the balance is water; wherein, the silicon dioxide concentration in the silica sol is 10 wt%, and the average particle size of silicon dioxide is 10-13 μm.

[0051] The material of the fiber fluff is PE / PP, the fiber fluff is upright, and the curl degree is 0.

[0052] (2) Drying the soaked fiber fluff so that the moisture content of the fiber fluff is 5 wt%, and the specific resistance of the fiber fluff after the drying treatment is 8´107 Ω·cm.

[0053] (3) Coat the bottom non-woven fabric with flocking glue and send it to a high-voltage electrostatic field. The coating ...

Embodiment 2

[0059] (1) Soak fiber fluff with a length of 2mm and a linear density of 2.5D in the finishing solution for 30 minutes. The temperature of the finishing solution is 50°C, the bath ratio is 1:35, and the weight percentage of each component in the finishing solution is For: 0.8wt% penetrant JFC, 3.5wt% K 2 SO 4 , 3wt% nonionic antistatic agent, 4.5wt% silica sol, 3wt% MgCl 2 , 2.5 wt% softener, 1.8wt% glacial acetic acid, and the balance is water; wherein, the silicon dioxide concentration in the silica sol is 13.6wt%, and the average particle size of silicon dioxide is 13-16 μm.

[0060] The material of the fiber fluff is PE / PET, the fiber fluff is upright, and the curl degree is 0.

[0061] (2) Drying the soaked fiber fluff so that the moisture content of the fiber fluff is 7.1 wt%, and the specific resistance of the fiber fluff after drying is 8.5´108 Ω·cm.

[0062] (3) Coat the bottom non-woven fabric with flocking glue and send it to a high-voltage electrostatic field. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com