Device for an installation structure fireproof test under engine suspension static loading

A technology of engine mounting and static loading, which is used in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as poor flame resistance, engine disengagement, failure, etc., to avoid construction difficulties, The effect of saving manufacturing cost and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

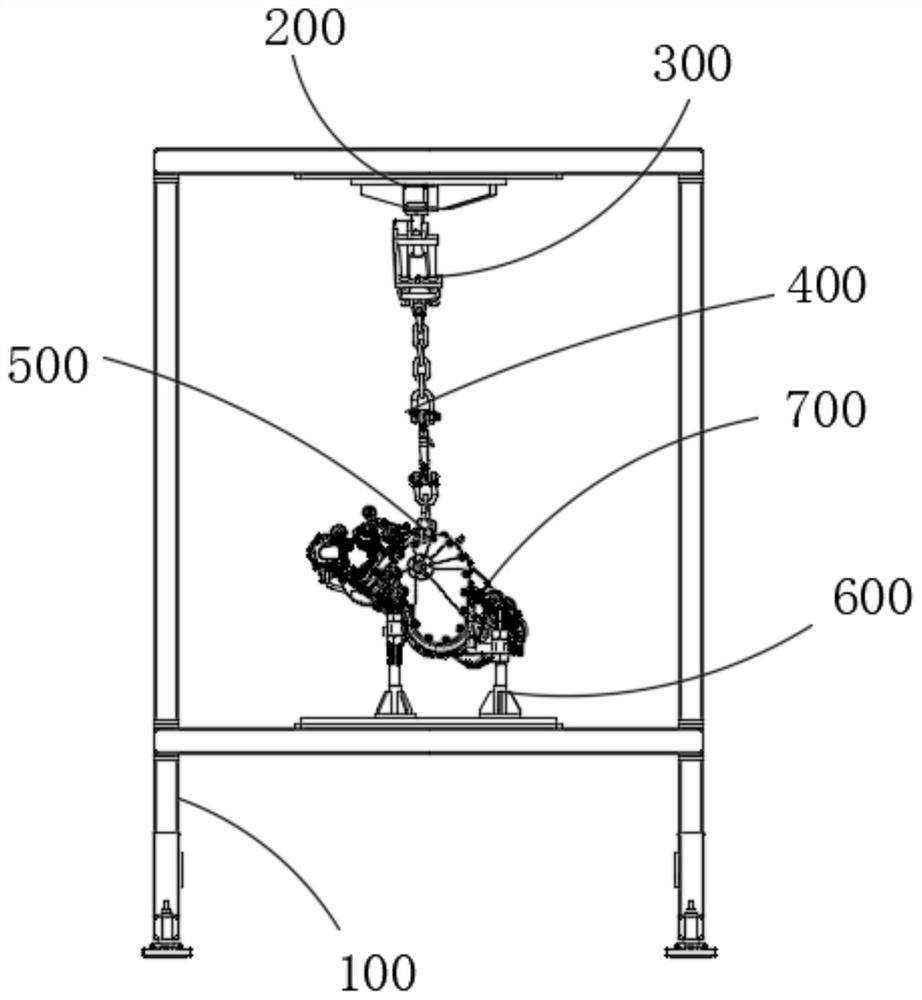

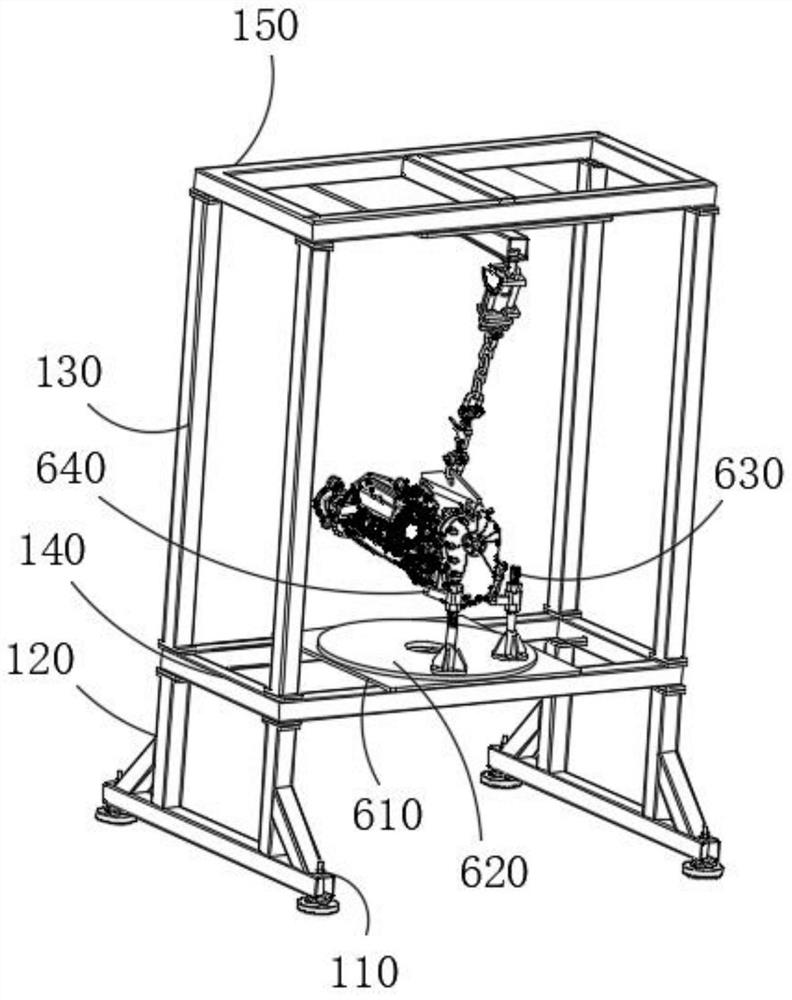

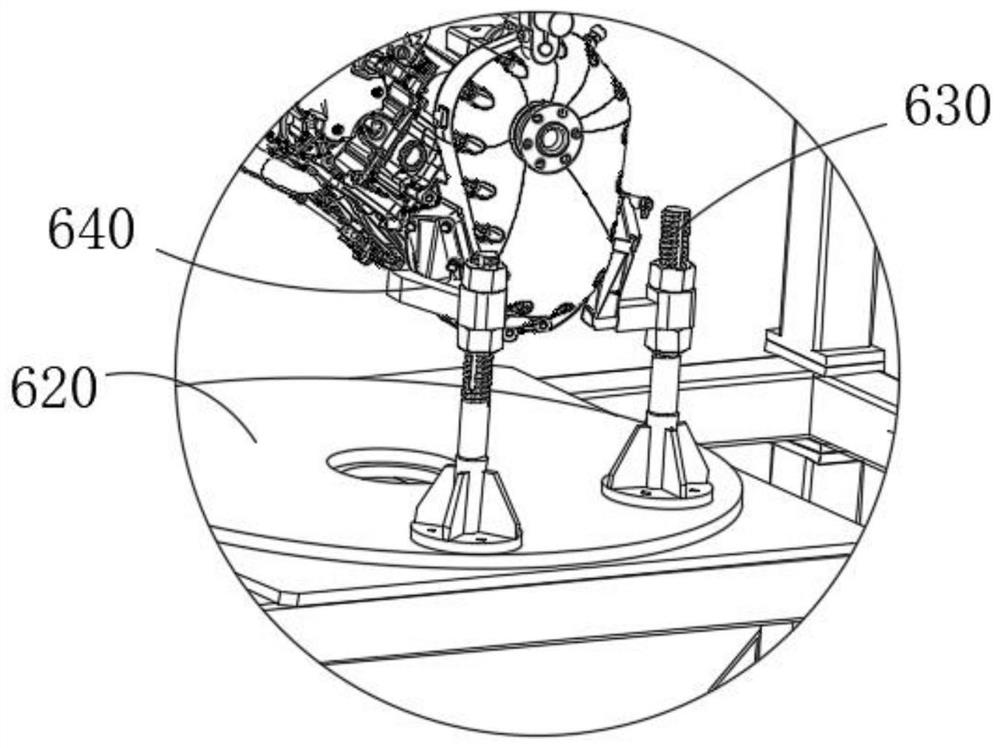

[0039] Refer to attached Figure 1-Figure 5 As shown in the present embodiment, a device for the fire test of an engine suspension under static loading, including a main frame mechanism 100, a rotatable upper cantilever mechanism 200, a load loading mechanism 300, a tension detection mechanism 400, and an engine center of mass adjustment mechanism 500 and the rotatable lower bracket mechanism 600, the rotatable upper cantilever mechanism 200 is fixedly installed on the upper part of the main frame mechanism 100, the rotatable upper cantilever mechanism 200 is connected to the load loading mechanism 300, and the lower end of the load loading mechanism 300 is connected to the tension detection mechanism 400 The lower end of the tension detection structure is fixedly connected to the engine center of mass adjustment mechanism 500, the engine center of mass adjustment mechanism 500 is fixedly arranged on the aeroengine 700, the lower part of the main frame mechanism 100 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com