Drying device for bolt machining

A drying device and bolt technology, applied in heating device, drying gas arrangement, drying solid materials without heating, etc., can solve the problems of long time consumption, inconvenient use, low efficiency, etc., to achieve convenient use and improve work efficiency , the effect of reducing the vibration force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

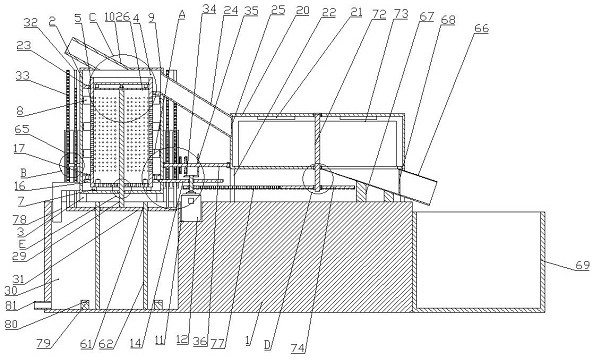

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-12 Shown: a drying device for bolt processing, including a workbench 1, a drainage mechanism is provided on one side of the workbench 1, a feed water rejection mechanism is provided on the workbench 1, and an outlet is provided on the side of the feed water rejection mechanism. Material drying mechanism, the side of the discharging drying mechanism is equipped with a collection mechanism,

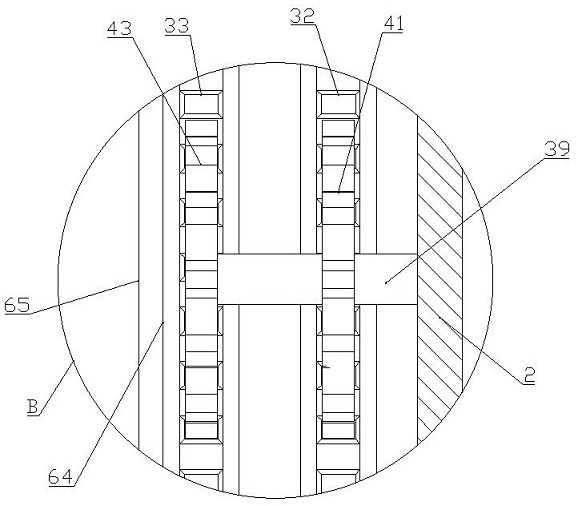

[0031] The water feeding mechanism includes a fixed platform 2 located above the workbench 1. Support legs 3 are installed at the four corners of the lower surface of the fixed platform 2. The lower ends of the support legs 3 are fixed on the upper surface of the workbench 1. Circular groove 4, is placed in circular groove 4 to get rid of bucket 5, has a plurality of permeable holes 6 on the side plate and base plate of bucket 5, and a plurality of first universal balls 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com