Rotary valve embedded half-bridge guide and control mechanism and fluid control valve

A fluid control valve, embedded technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of complex structure, large volume, low commutation frequency, etc., to achieve the overall volume Small, simple and ingenious structure, the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

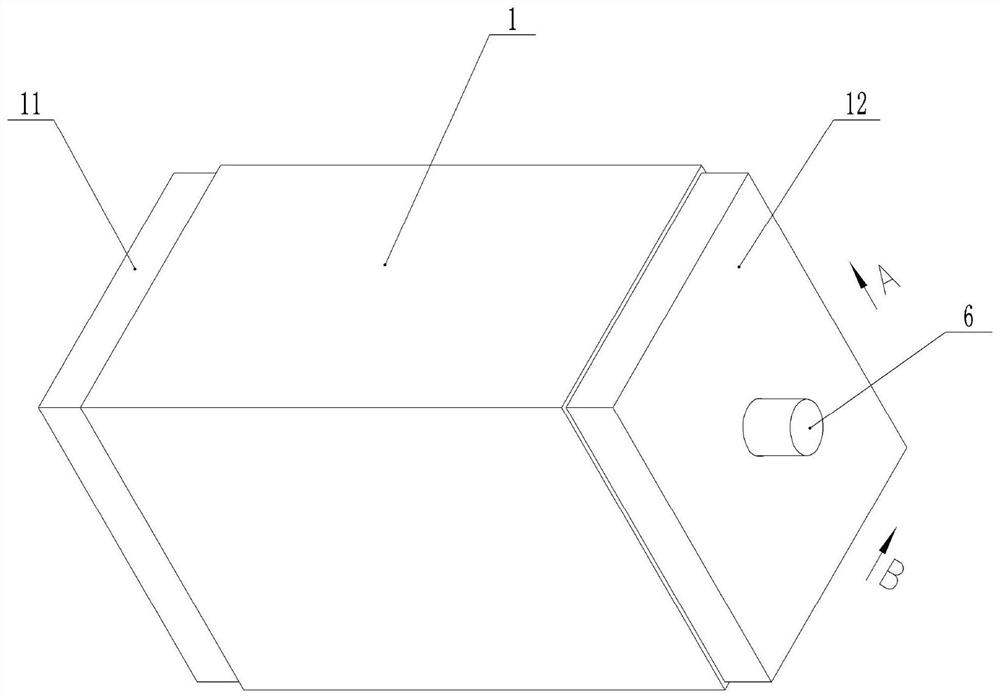

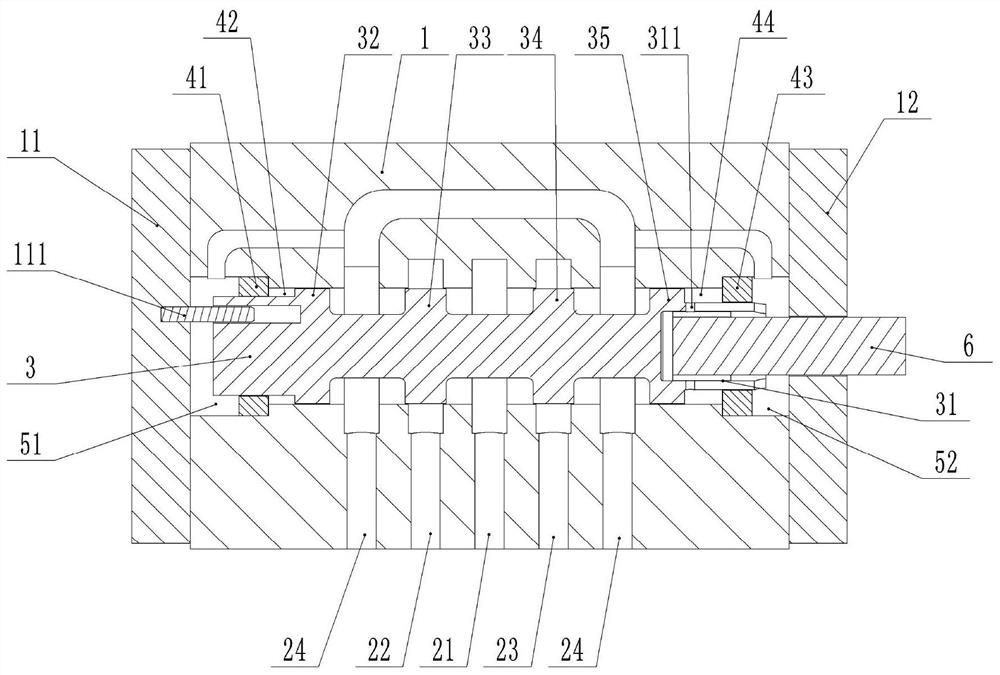

[0049] Example figure 1 As shown, the rotary valve embedded half-bridge pilot control mechanism and the fluid control valve include the valve body 1, the main valve core 3 and the pilot valve core 6, the main valve core 3 is slidably connected inside the valve body 1, and the pilot valve core 6 rotates Connected to the right end of the main spool 3, the left end of the valve body 1 is the left end cover 11, and the left end cover 11, the valve body 1 and the left end of the main spool 3 form a left adjustment cavity 51; the left end cover 11 is fixedly connected with a positioning pin 111 for positioning The pin 111 is arranged eccentrically with the main valve core 3, and the left end of the main valve core 3 is provided with a slide hole, and the positioning pin 111 is slidably connected with the left end of the main valve core 3 through the slide hole. The right end of the valve body 1 is the right end cover 12, the right end cover 12, the right end of the valve body 1 and ...

Embodiment 2

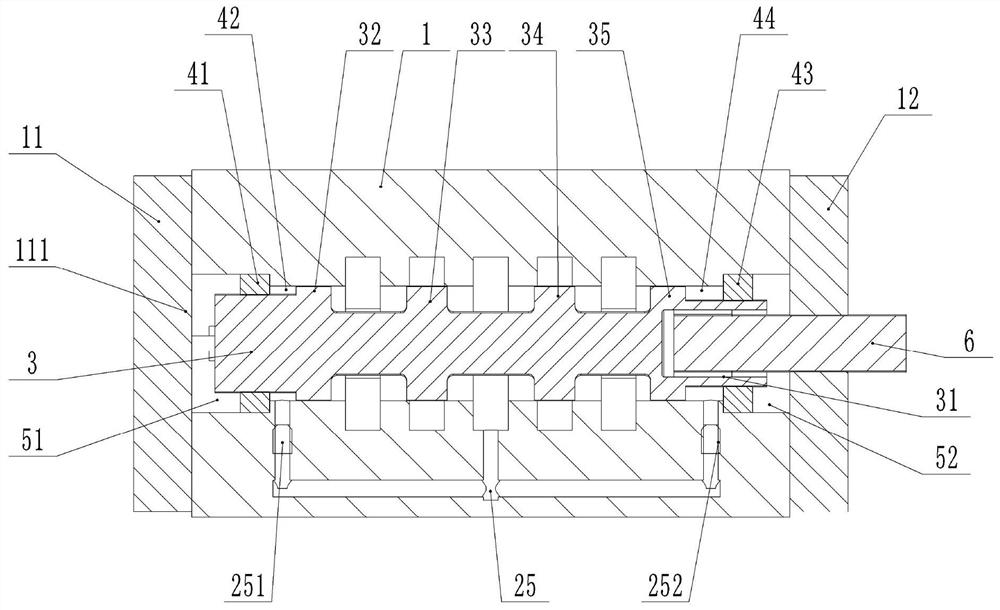

[0059] The difference between this embodiment and Embodiment 1 is that 12 oil grooves 61 are provided in this embodiment, and the 12 oil grooves 61 are evenly distributed along the circumferential direction of the pilot valve core 6, and there are 12 corresponding inner oil ports 311. The 12 inner oil ports 311 are evenly distributed along the circumferential direction of the main valve core 3, the positions of the 12 inner oil ports 311 can correspond to the positions of the 12 oil grooves 61, and the increase in the number of inner oil ports 311 can increase the flow area. When the control valve is in use, every time the pilot spool 6 rotates one revolution, the pilot stage valve port will switch 12 times to realize further amplification of the switching frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com