Oil pump variable displacement mechanism adopting hydraulic lead screw and control method of oil pump variable displacement mechanism

A variable mechanism and control method technology, applied in pump control, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems affecting the responsiveness and control accuracy of proportional hydraulic pumps, large throttling loss, etc., to achieve convenient operation and maintenance. , The effect of small throttling loss and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below, and the accompanying drawing shows an implementation example of the present invention. The present invention can be implemented in different forms, and is not limited to this embodiment case.

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

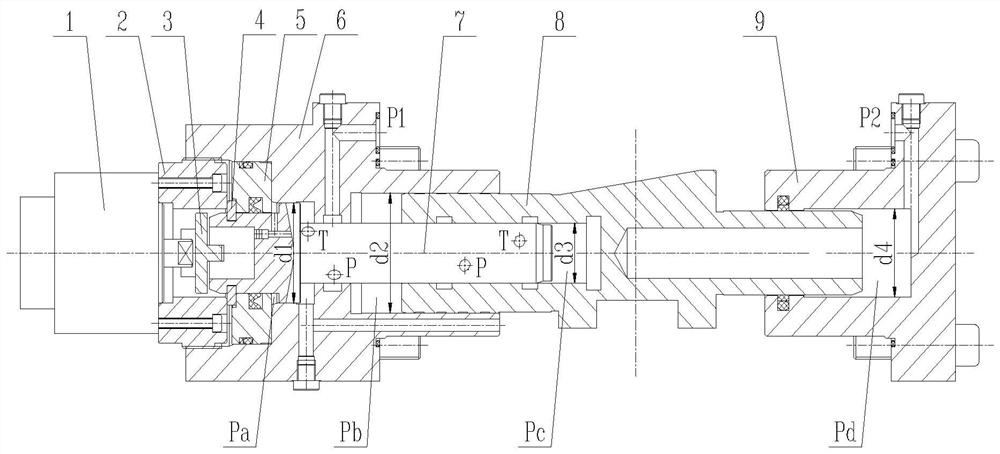

[0022] Among them, such as figure 1 As shown, the oil pump variable mechanism of the present invention includes a servo motor 1, a pressing block 2, an Oldham coupling 3, a snap ring 4, an inner and outer sealing seat 5, a front end cover 6, a micro-actuator control rod 7, and an oil pump variable Push rod 8, rear end cover 9, the servo motor 1 is installed on the compression block 2, the compression block 2 is installed on the front end cover 6, the two ends of the Oldham coupling 3 have a servo motor 1 and a micro actuator Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com