A kind of water-soluble thermosetting acrylic resin and preparation method thereof

An acrylic resin and thermosetting technology, applied in the field of water-soluble thermosetting acrylic resin and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

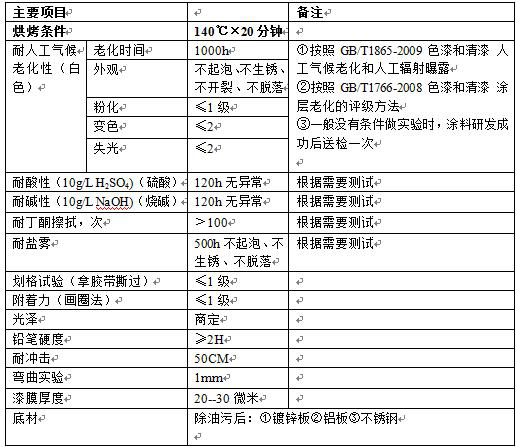

Image

Examples

Embodiment 1

[0027] The water-soluble thermosetting acrylic resin of the present embodiment, the formula composition table is as follows:

[0028] Table 1: Formulation Composition Table

[0029]

[0030] The preparation process of the water-soluble thermosetting acrylic resin of the present embodiment comprises the following steps:

[0031] 1. Check the equipment and various raw materials, and start production only after meeting the feeding conditions;

[0032] 2. First add the accurately measured bottom materials 1 and 2 to the reaction kettle, turn on the stirring, start to heat up, rise to the reflux temperature, and keep for about 10-20 minutes;

[0033] 3. After 4-4.5 hours, the mixed monomer was added dropwise at a uniform speed, and kept under reflux for 1.5 hours;

[0034] 4. Add feed 1 dropwise for 15 minutes, keep for 1 hour, with reflux;

[0035] 5. Add the feed 2 dropwise for 10 minutes, keep it for 2 hours, there is reflux, then cool down, drop to 100℃±5℃, add the thinni...

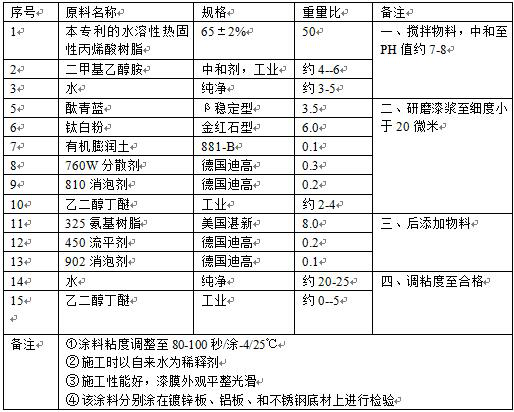

Embodiment 2

[0044] The formula of the water-soluble thermosetting acrylic resin of the present embodiment, the composition formula composition table is as follows:

[0045] Table 2: Formulation Composition Table

[0046]

[0047] The preparation process of the water-soluble thermosetting acrylic resin of the present embodiment comprises the following steps:

[0048] 1. Check the equipment and various raw materials, and start production only after meeting the feeding conditions;

[0049] 2. First add the accurately measured bottom materials 1 and 2 to the reaction kettle, turn on the stirring, start to heat up, rise to the reflux temperature, and keep for about 10-20 minutes;

[0050] 3. After 4-4.5 hours, the mixed monomer was added dropwise at a uniform speed, and kept under reflux for 1.5 hours;

[0051] 4. Add the feeding material ① dropwise for 15 minutes, keep it for 1 hour, there is reflux;

[0052] 5. Add the feeding material ② dropwise for 10 minutes, keep it for 2 hours, ther...

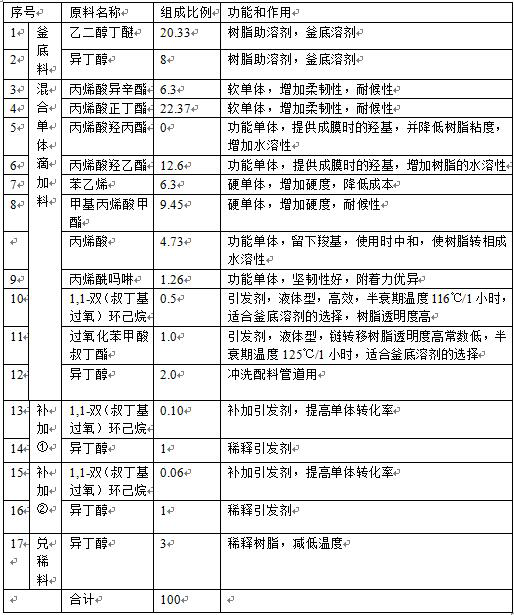

Embodiment 3

[0061] The water-soluble thermosetting acrylic resin formula of the present embodiment is composed, and the composition formula table is as follows:

[0062] Table 3: Formulation composition table

[0063]

[0064] The preparation process of the water-soluble thermosetting acrylic resin of the present embodiment comprises the following steps:

[0065] 1. Check the equipment and various raw materials, and start production only after meeting the feeding conditions;

[0066] 2. First add the accurately measured bottom materials ① and ② to the reaction kettle, turn on the stirring, start to heat up, rise to the reflux temperature, and keep it for about 10-20 minutes;

[0067] 3. The mixed monomer is added dropwise at a uniform speed in 4--4.5 hours, and kept under reflux for 1.5 hours;

[0068] 4. Add the feeding material ① dropwise for 15 minutes, keep it for 1 hour, there is a small reflux;

[0069] 5. Add the feeding material ② dropwise for 10 minutes, keep it for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com