Combined treatment method for regenerated high-concentration salt wastewater of sodium ion exchanger

A sodium ion exchanger and combined treatment technology, which is applied in the field of combined treatment of high-concentration salt wastewater regenerated by sodium ion exchangers, can solve the problems of high price, high energy consumption, and unfavorable promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A steel company uses a sodium ion exchanger to prepare softened water. After the resin of the sodium ion exchanger is saturated, it uses 6% sodium chloride solution to regenerate the resin. Through the control of the wastewater discharge valve and discharge pipeline, the low-salt wastewater is discharged to In the sewage treatment plant in the factory area, the wastewater is treated to become qualified reclaimed water, and the reclaimed water is prepared through a sodium ion exchanger to soften water; the regenerated high-concentration salt wastewater generated during the resin regeneration process is collected through the control of the concentrated salt wastewater discharge valve and the concentrated salt wastewater discharge pipeline.

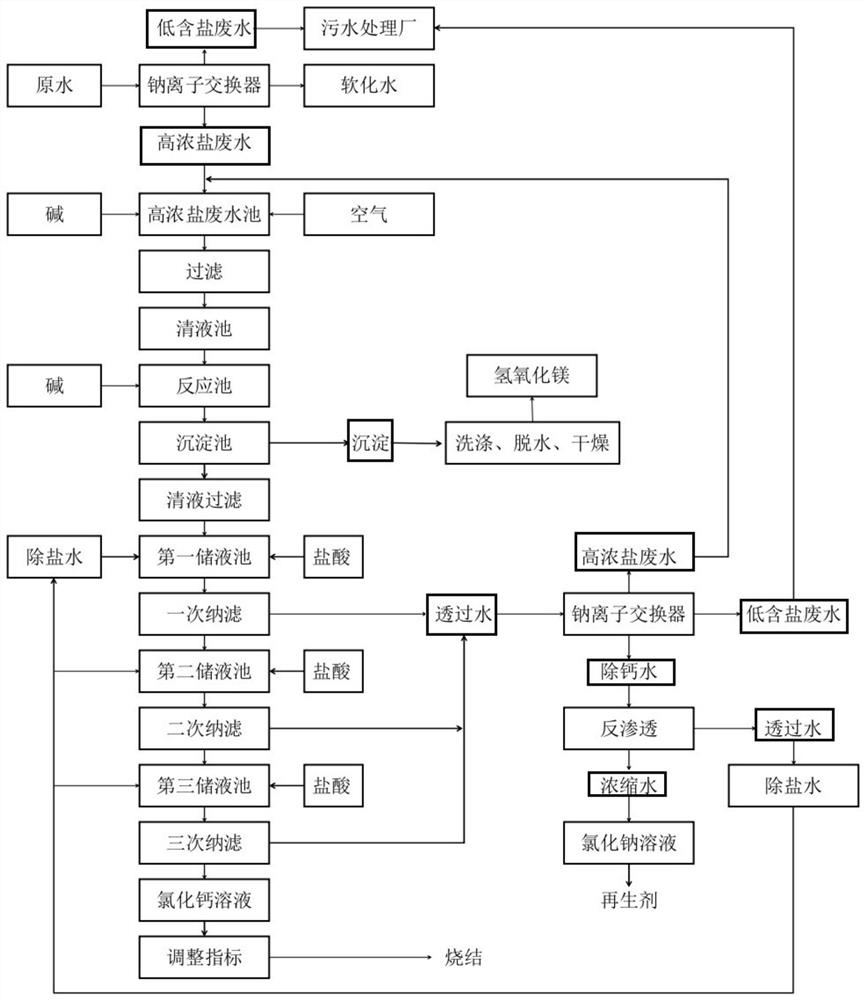

[0032] A combined treatment method for high-concentration salt wastewater regenerated by a sodium ion exchanger, the treatment process is as follows:

[0033]S1, the high-concentration salt wastewater regenerated by the sodium ion exch...

Embodiment 2

[0047] A steel company uses a sodium ion exchanger to prepare softened water. After the resin of the sodium ion exchanger is saturated, 8% sodium chloride solution is used to regenerate the resin. Through the control of the wastewater discharge valve and discharge pipeline, the low-salt wastewater is discharged to In the sewage treatment plant in the factory area, the wastewater is treated to become qualified reclaimed water, and the reclaimed water is prepared through a sodium ion exchanger to soften water; the regenerated high-concentration salt wastewater generated during the resin regeneration process is collected through the control of the concentrated salt wastewater discharge valve and the concentrated salt wastewater discharge pipeline.

[0048] A combined treatment method for high-concentration salt wastewater regenerated by a sodium ion exchanger, the treatment process is as follows:

[0049] S1, lead the high-concentration salt wastewater regenerated by the sodium io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com