Injection molding part mold parameter optimization method based on GA-ELM-GA

An optimization method and technology of injection molded parts, applied in the direction of gene model, design optimization/simulation, genetic rules, etc., can solve problems such as warpage and deformation of injection molded parts, and achieve the effect of improving the quality of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

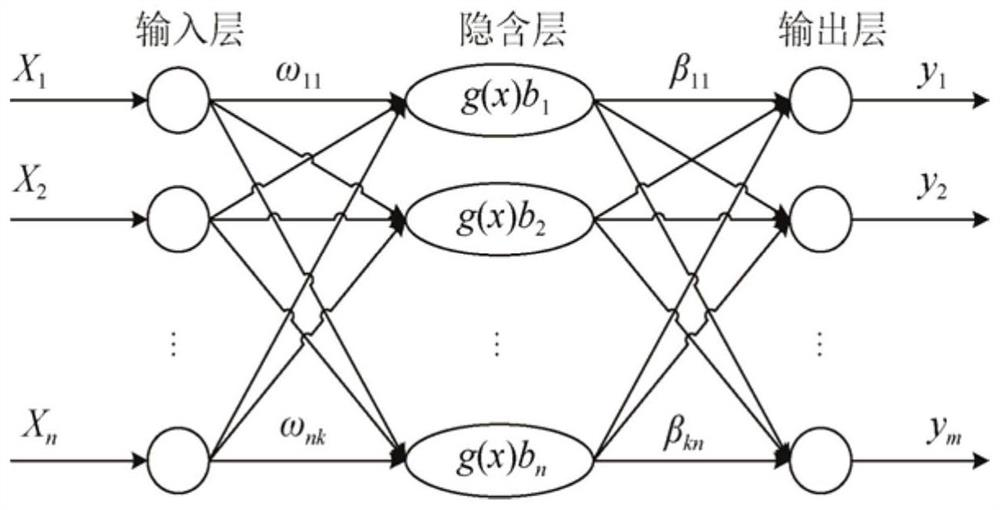

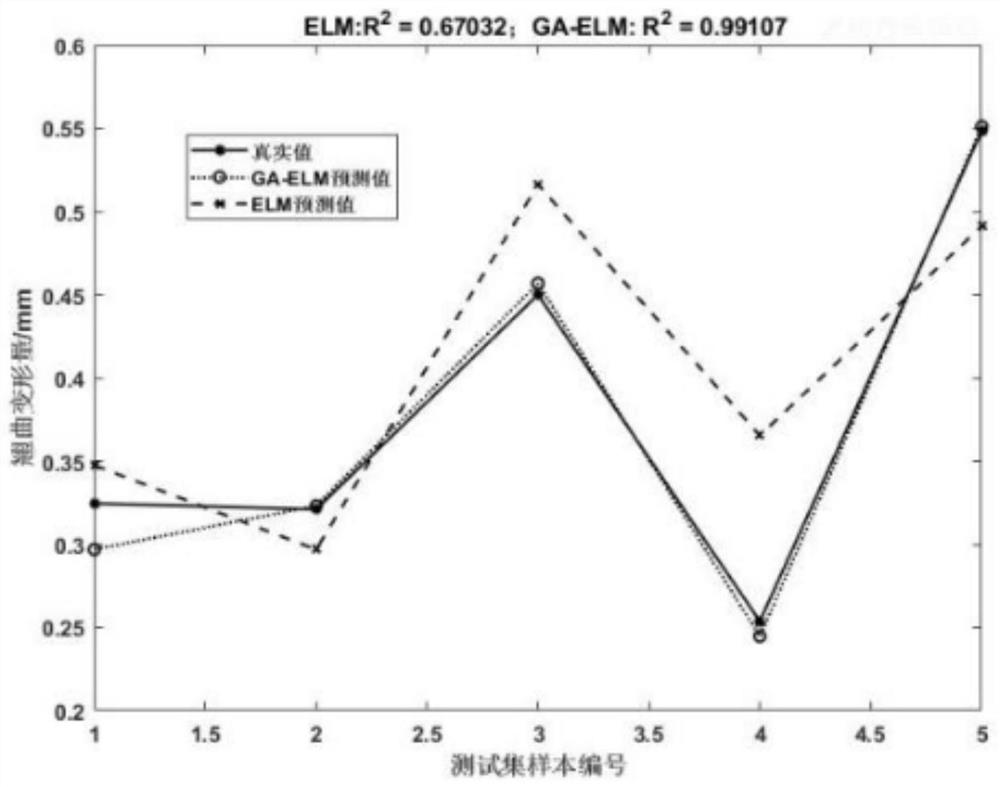

Method used

Image

Examples

Embodiment Construction

[0028] Analysis on the structure and manufacturability of the electric button cover shell

[0029] Electric buckle cover structure

[0030] The basic size of the electrical buckle cover is 670mm×104mm×70mm, which belongs to the size of medium-sized parts, and is composed of figure 1 The structural diagram of the electrical buckle cover shows that some areas of the plastic part are irregular in shape, containing various molding features such as bosses, holes, ribs, and grooves, and are prone to warping and deformation.

[0031] Manufacturability Analysis of Electric Button Cover Shell

[0032] The plastic part of the electrical button cover shell is used in the packaging of electrical parts, mainly to protect personal safety and maintain the life of electrical parts, and has high requirements in terms of performance and appearance. The maximum thickness of the plastic part measured by NX12.0 is 4.91, and the average wall thickness is 1.94. In some areas, the wall thickness is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com