Machining tool of toothed adjusting sleeve assembly and machining method of toothed adjusting sleeve assembly

A technology for adjusting sleeves and components, applied in the field of rolling mill parts processing, can solve problems such as inability to ensure accuracy, and achieve the effects of accurate adjustment of feed size, flexible rotation, quality assurance and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

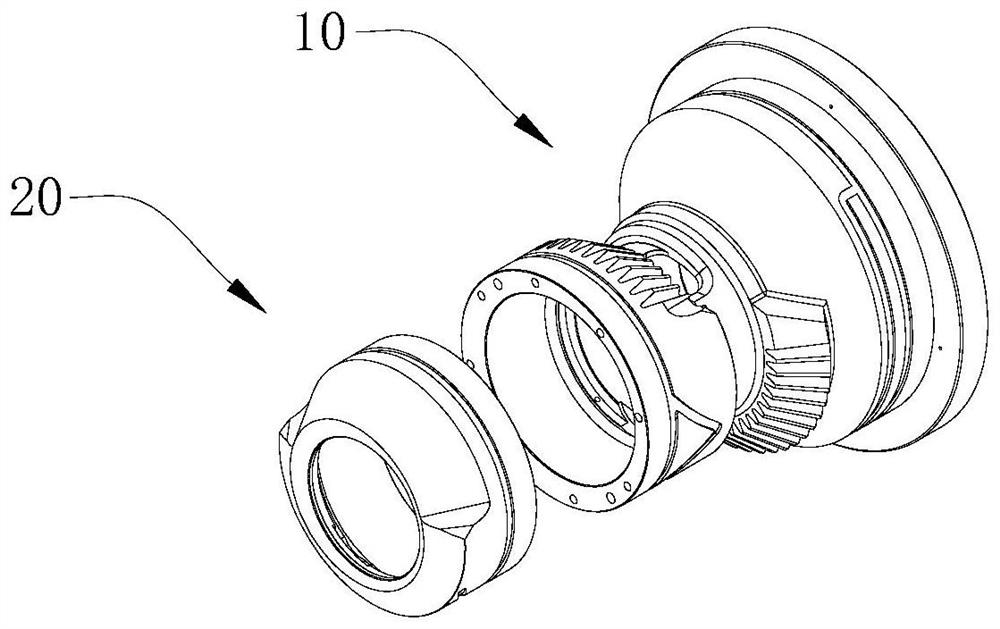

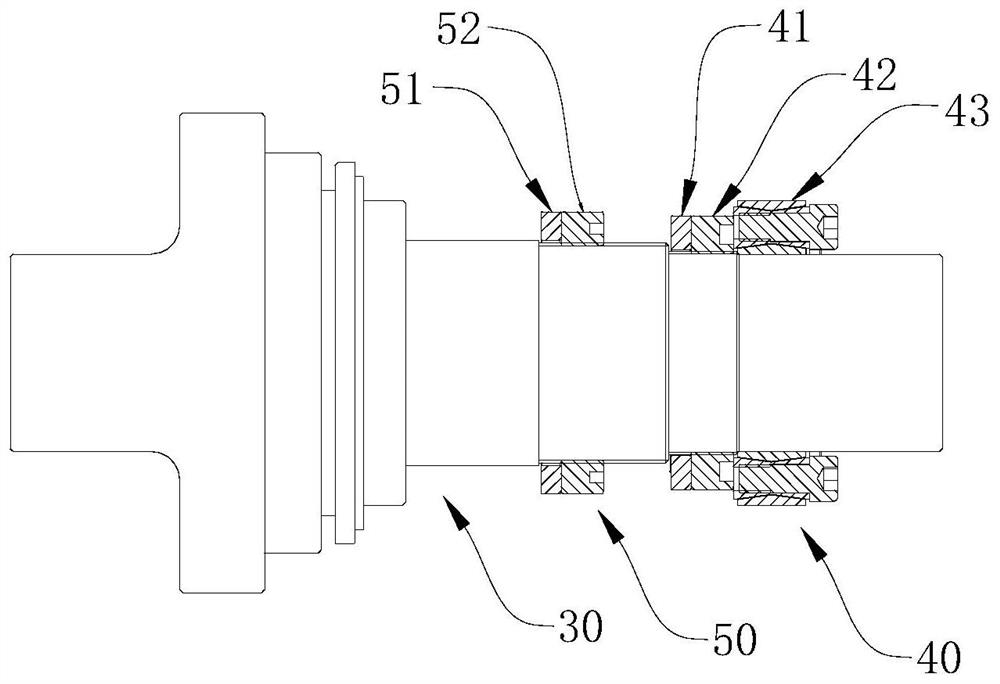

[0054] Please refer to figure 2 , a processing tool for a toothed adjustment sleeve assembly, comprising: a mandrel 30 , a first limit assembly 40 and a second limit assembly 50 . The mandrel 30 is provided with a first positioning notch 32 and a second positioning notch 33 . The first limiting component 40 is sleeved on the mandrel 30 , and is used to limit the toothed adjusting sleeve 10 after matching with the first positioning notch 32 , so as to facilitate the clamping of the toothed adjusting sleeve 10 . The second limiting component 50 is also sleeved on the mandrel 30 , and is used to limit the adjusting sleeve 20 after matching with the second positioning notch 33 , so as to facilitate the clamping of the adjusting sleeve 20 .

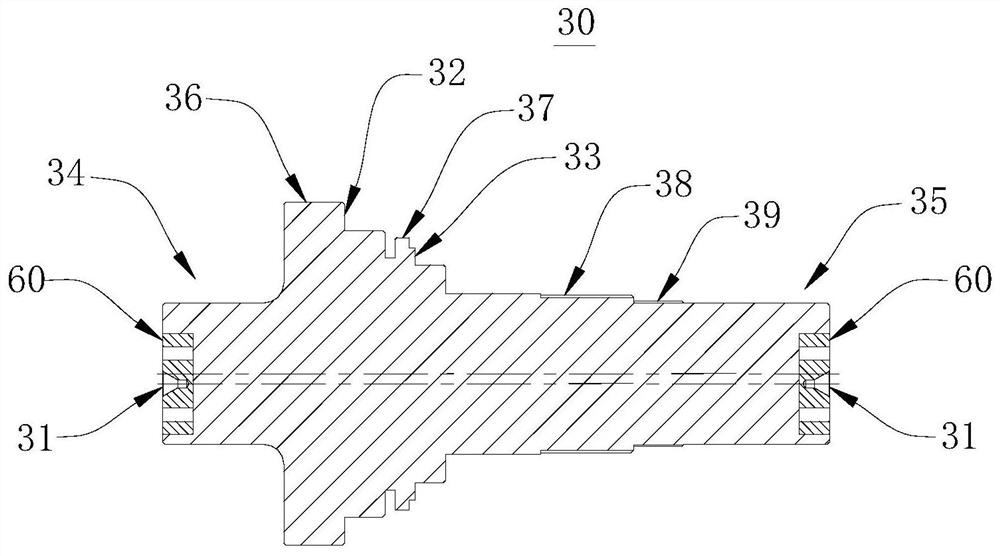

[0055] Please refer to Figure 3 to Figure 5 , the mandrel 30 is a structure of revolution, which itself has an axis. The two ends of mandrel 30 are respectively embedded with top cone plate 60, and top cone plate 60 is connected with mand...

Embodiment 2

[0061] A processing method for a toothed adjusting sleeve assembly, using the above-mentioned processing tool for the toothed adjusting sleeve assembly for clamping and processing, comprising the following steps:

[0062] S10: processing the toothed adjustment sleeve 10, which includes the following steps:

[0063] S11: Forge the blank and perform normalizing treatment, and at the same time conduct ultrasonic flaw detection to ensure that the material is qualified;

[0064] S12: Outer circle and inner hole of blank rough turning;

[0065] S13: According to the direction of the inner hole and eccentricity, the direction positioning surface 11 of the outer circle of the large end face is milled, which is used to determine the direction of the adjusting tooth and the rotating tooth;

[0066] S14: Clamping the outer circle of the big end, rough milling the rotating gear and adjusting gear;

[0067] S15: quenching and tempering treatment;

[0068] S16: Semi-finishing the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com