Assembling device for built-in motor of electric motorcycle

An electric motorcycle and assembly device technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of difficult to grasp accuracy, low efficiency, inconvenience, etc., to prevent damage to parts and reduce the amount of compression , the effect of reducing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

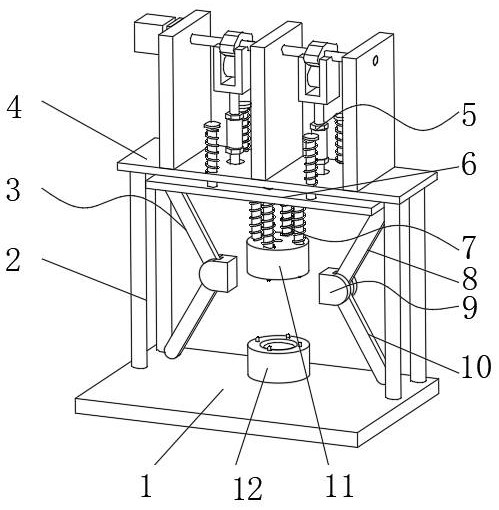

[0037] An assembly device for a built-in motor of an electric motorcycle, such as figure 1 , 2 As shown in . The bottom of the transition plate 6 is connected with a transition plate 6, the bottom of the transition plate 6 is provided with a pressure applying mechanism 7, the upper mold 11 is fixedly installed on the bottom of the pressure applying mechanism 7, the lower mold 12 is fixedly installed on the top outer wall of the base 1, the base 1 and the transition plate 6 Two groups of symmetrical supporting mechanisms 3 are provided on the outer wall on the opposite side. The driving mechanism 5 includes a motor 13 and a rotating shaft 14. At least three load-bearing plates 15 are fixed on the top outer wall of the top plate 4 by bolts. The rotating shaft 14 is rotatably connected to the On the inner wall of the bearing plate 15, the motor 13 is fixed on the outer wall of one of the bearing plates 15 by bolts, and its output shaft is connected with the rotating shaft 14 throu...

Embodiment 2

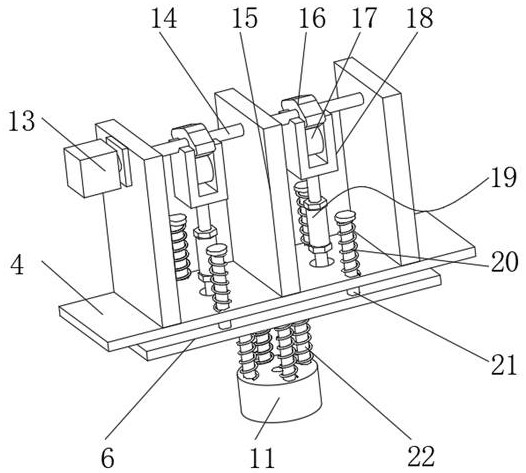

[0040] An assembly device for a built-in motor of an electric motorcycle, such as figure 2 As shown, in order to solve the limit problem; this embodiment makes the following improvements on the basis of Embodiment 1: the pressure applying mechanism 7 includes a slide bar 22 and a spring 2, and the bottom of the slide bar 22 is fixed to the On the top outer wall of the upper mold 11 , the outer wall of the second slide bar 22 is slidably connected to the inner wall of the transition plate 6 , and the second spring is sleeved on the outer wall of the second slide bar 22 .

[0041] When this embodiment is in use, it is difficult to maintain the pressing distance and the pressing force after the pressing is in place no matter whether the cylinder, oil cylinder, threaded screw or the device is used for pressing, and the device is equipped with two springs. , the pressing force is applied to the upper mold 11 through the spring 2. On the one hand, the elastic force of the spring 2 ...

Embodiment 3

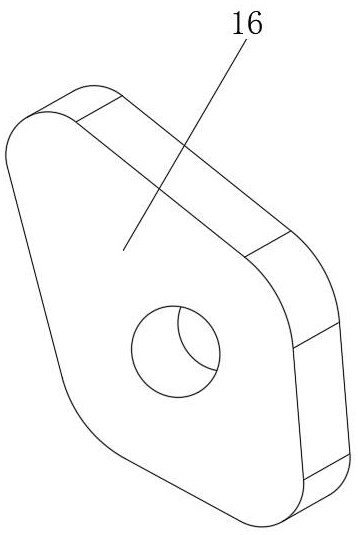

[0043] An assembly device for a built-in motor of an electric motorcycle, such as Figure 4 As shown, in order to solve the limit problem; this embodiment makes the following improvements on the basis of embodiment 2: the connecting assembly 19 includes two screw rods 23 and a sleeve 24, and the two screw rods 23 rotate in opposite directions The two sides of the sleeve 24 are threadedly connected, and the outer walls of the two screw rods 23 are threaded with locknuts 25 .

[0044] When this embodiment is in use, the device is provided with a screw rod 23 and a sleeve 24. When the sleeve 24 is twisted, it can change the length of the entire connecting assembly 19 through thread action, so that the device, on the one hand, is used for fixing For different types of rotors, the pressing force can be adjusted by twisting the sleeve 24. On the other hand, for different types of rotors, the pressing distance can be adjusted by twisting the sleeve 24, which is more practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com