Automatic cable stripping device integrating longitudinal cutting and annular cutting

A technology of automatic device and slitting device, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., which can solve the problems of low efficiency, the need for workers to manipulate the walking track, and poor surface roughness after peeling. , to achieve the effect of improving cutting quality and improving cutting and peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

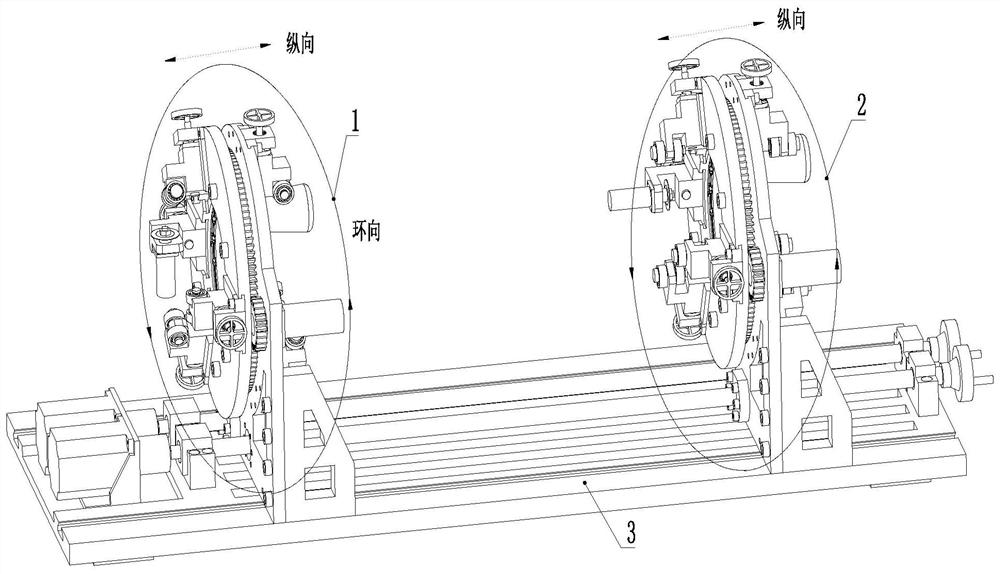

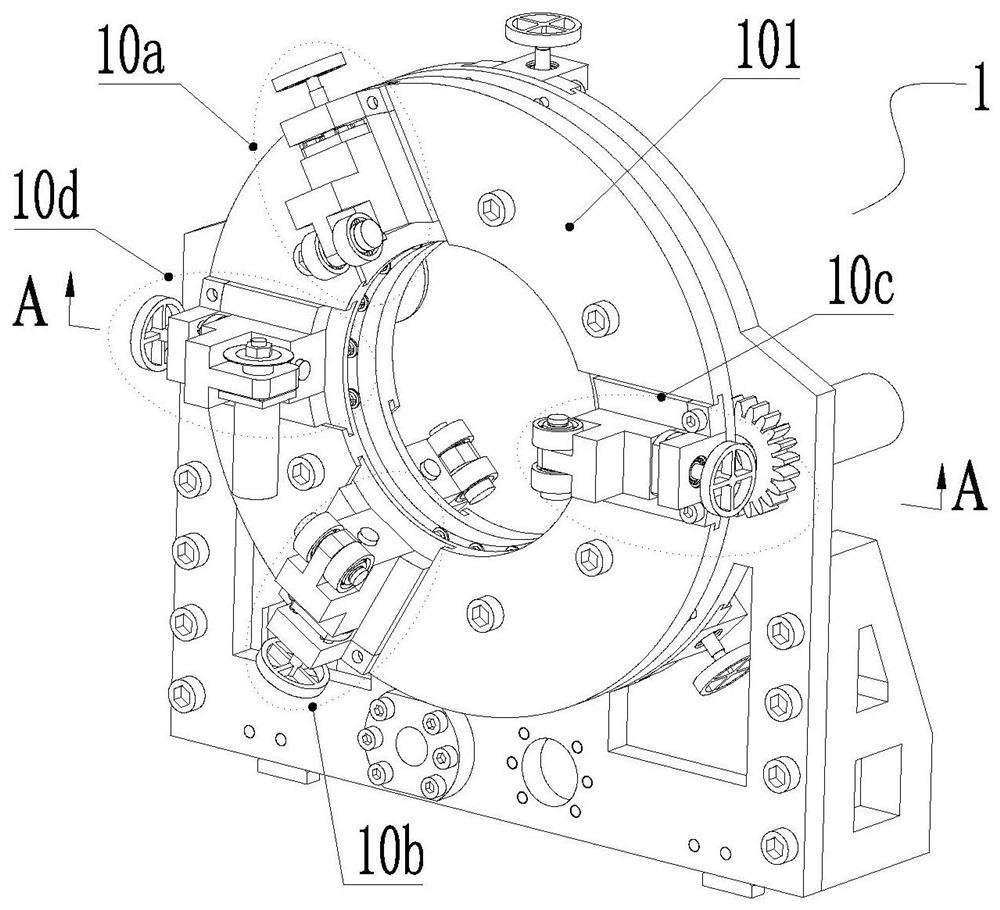

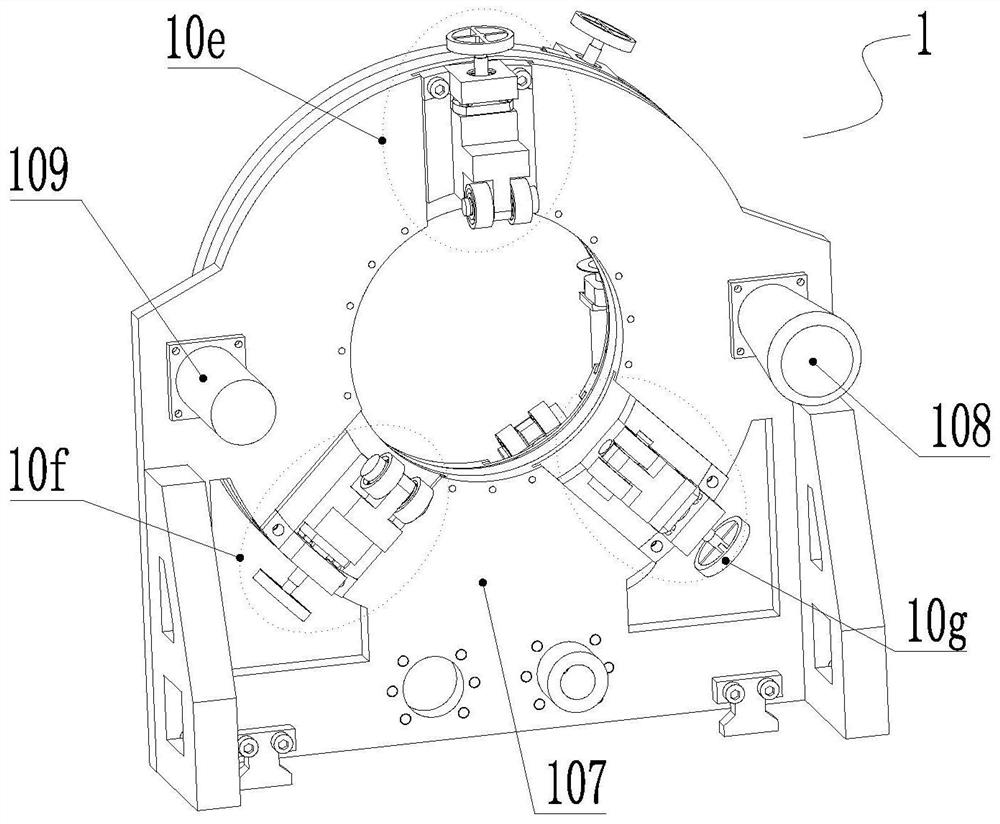

[0031] The integrated slitting and ring cutting cable stripping automation device mainly consists of three components: a slitting device 1, a ring cutting device 2 and a base double screw nut mechanism 3, such as figure 1 shown. The slitting device 1 is located at the motor-driven end of the base double-screw nut mechanism 3, and the two are connected and limited by an inverted T-shaped slider 111a, and the inverted T-shaped slider 111a is fixed to the gear base plate 107 (for details, see Figure 5 ), the limit moves in the slideway, and the slitting device 1 passes through the large stepping / servo drive motor 302b or the large handwheel 308b on the base double screw nut mechanism 3 (see for details Figure 14 ) to move in the vertical direction. The circular cutting device 2 is located at the non-driving end of the motor of the base double screw nut mechanism 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com