Method for determining cavitation bubble separation point of runner blade through external characteristic indexes

A technology of cavitation bubbles and runner blades, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the negative impact on the safe and stable operation of hydraulic machinery, affect the accuracy of cavitation evaluation of runner blades, Problems such as cavitation bubbles and cavitation bubble detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

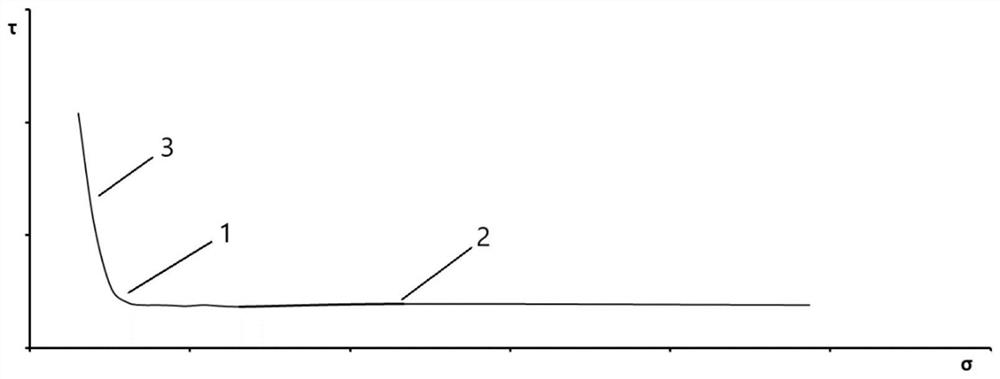

[0064] A method for determining the separation point of cavitation bubbles in runner blades through external characteristic indexes, the operation steps are as follows:

[0065] 1) Start the hydraulic mechanical model test system;

[0066] 2) The hydraulic mechanical model is running in a non-cavitation state;

[0067] 3) Keep the hydraulic mechanical model running stably;

[0068] 4) Collect the cavitation coefficient of the hydraulic mechanical model;

[0069] 5) Collect the energy fluctuation signal at the tailwater cone of the hydraulic mechanical model;

[0070] 6) Calculate the energy change rate of the energy fluctuation signal at the tailwater cone of the hydraulic mechanical model:

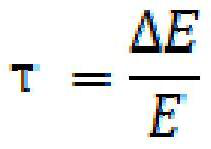

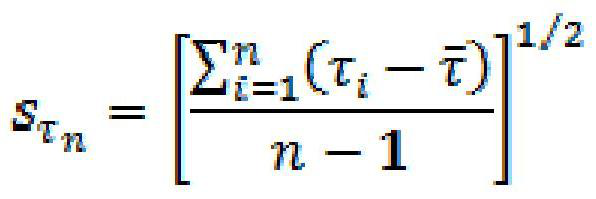

[0071] The energy change rate of the energy fluctuation signal at the tailwater cone of the hydraulic mechanical model is calculated according to the following formula:

[0072]

[0073] In the formula:

[0074] τ: energy change rate of the energy fluctuation signal at the tailwat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com