Correction method, device and equipment of X-ray luggage inspection equipment and storage medium

A luggage inspection and X-ray technology, which is applied in the direction of measuring devices, nuclear radiation exploration, conveyor control devices, etc., can solve the problems of single correction method and low security inspection efficiency of security inspection machines, so as to solve the single correction method and improve security inspection efficiency , Overcoming the effect of image deformation and abnormal gray scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

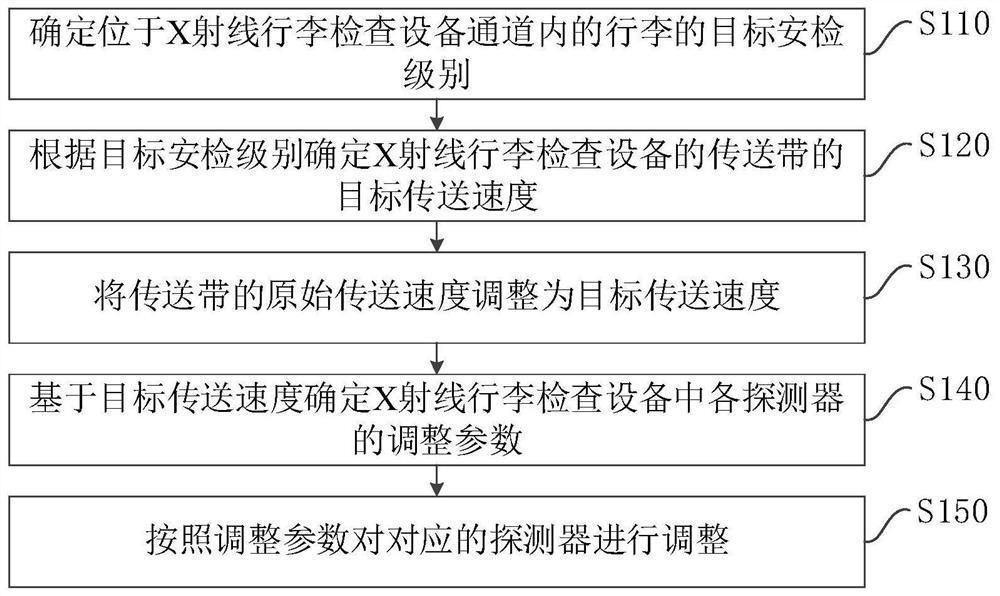

[0030] figure 1 It is a flow chart of a calibration method for X-ray luggage inspection equipment provided by Embodiment 1 of the present invention. This embodiment is applicable to the case of calibrating the detector in the X-ray luggage inspection equipment. The calibration device of the X-ray baggage inspection equipment can be implemented by the calibration device of the X-ray luggage inspection device, which can be realized by software and / or hardware, and can be configured in a computer device, such as a server, workstation, personal computer, etc. The method specifically includes the following step:

[0031] S110. Determine the target security inspection level of the baggage located in the channel of the X-ray baggage inspection equipment.

[0032] X-ray baggage inspection equipment, also known as X-ray baggage security inspection machine, is an electronic device that sends the baggage to be inspected into the X-ray inspection channel by means of a conveyor belt to co...

Embodiment 2

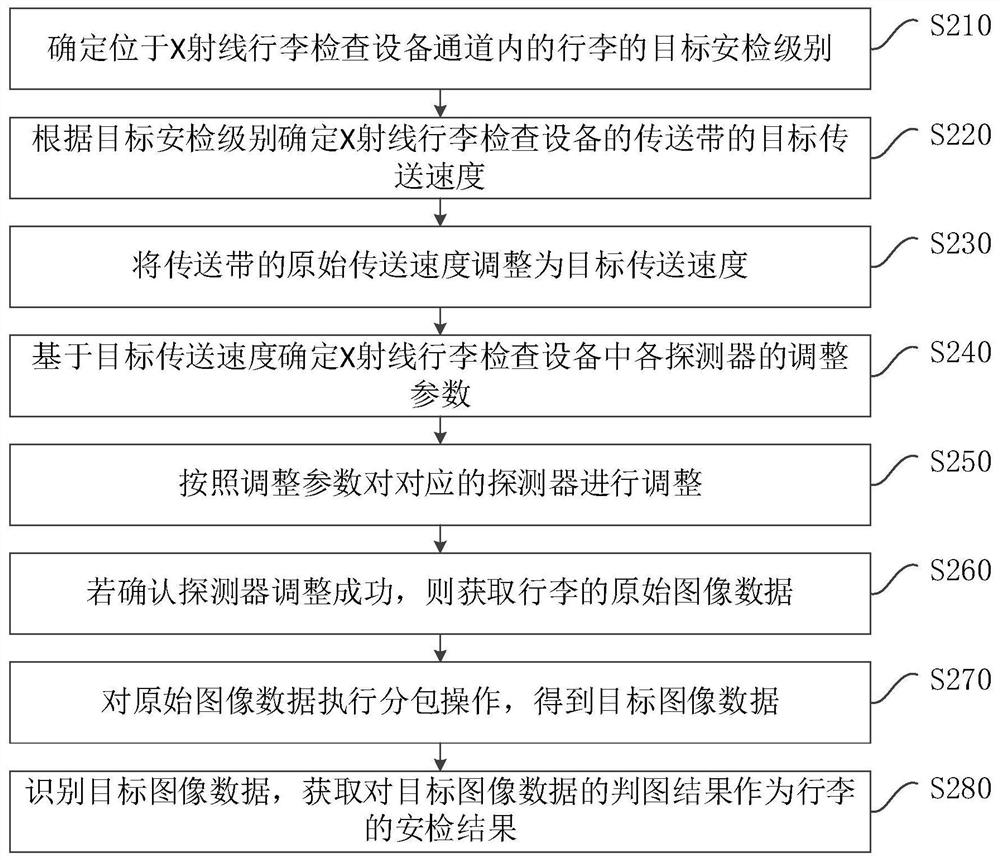

[0066] figure 2 It is a flow chart of a calibration method for X-ray baggage inspection equipment provided by Embodiment 2 of the present invention. This embodiment is based on the foregoing embodiments, and further refines and supplements the technical solution proposed by the present invention. This embodiment It can be applied to a server, and may specifically include the following steps:

[0067] S210. Determine the target security inspection level of the baggage located in the channel of the X-ray baggage inspection equipment.

[0068] S220. Determine the target transmission speed of the conveyor belt of the X-ray baggage inspection device according to the target security inspection level.

[0069] S230. Adjust the original transmission speed of the conveyor belt to the target transmission speed.

[0070] In this embodiment, different target security inspection levels correspond to different conveying speeds of the conveyor belt, and also correspond to different distri...

Embodiment 3

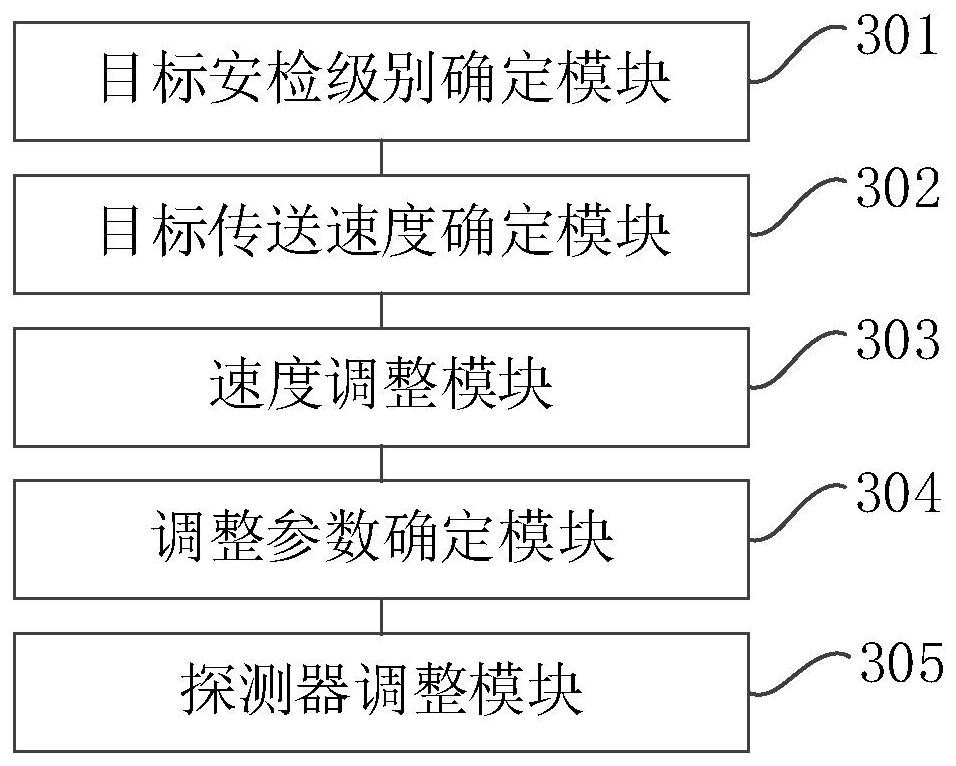

[0099] image 3 It is a schematic structural diagram of a calibration device of an X-ray luggage inspection device provided in Embodiment 3 of the present invention. The device may specifically include the following modules:

[0100] A target security check level determination module 301, configured to determine the target security check level of luggage located in the channel of the X-ray luggage inspection equipment;

[0101] A target transmission speed determination module 302, configured to determine the target transmission speed of the conveyor belt of the X-ray baggage inspection device according to the target security inspection level;

[0102] a speed adjustment module 303, configured to adjust the original transmission speed of the conveyor belt to the target transmission speed;

[0103] An adjustment parameter determination module 304, configured to determine the adjustment parameters of each detector in the X-ray baggage inspection device based on the target transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com